A detection method for the coating degree of cement emulsified asphalt on mineral materials

A technology of cement emulsified asphalt and a detection method, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by chemical reaction of materials, etc. , to achieve the effect of accurate and reliable test results and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

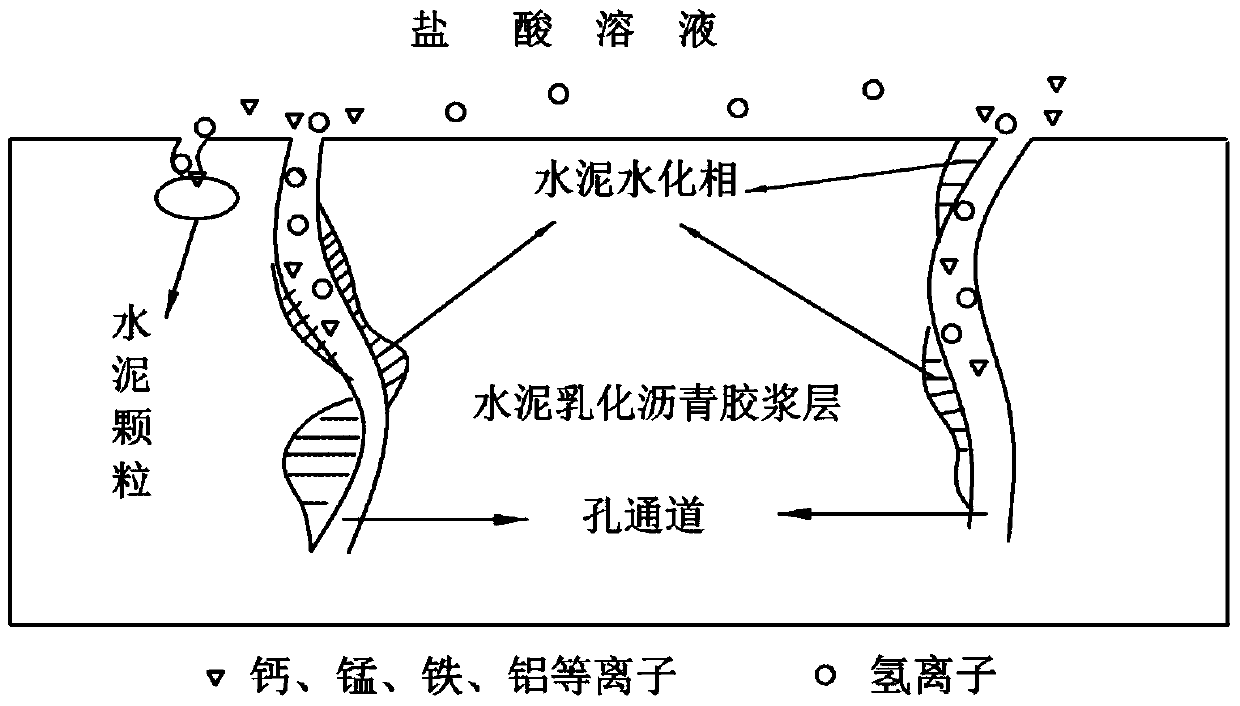

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Cement emulsified asphalt mortar on the aggregate surface of the cement emulsified asphalt mixture with a particle size of 9.5mm-13.2mm (in this embodiment, the emulsified asphalt in the cement emulsified asphalt mortar is cationic emulsified asphalt, with a solid content of 60%, and the emulsified asphalt quality and The mass ratio of cement is 3:2, and the mineral material is limestone.) Coating performance of the layer under hydrochloric acid erosion:

[0044] Wash the aggregate, dry it at 50-60°C for 1.5h, and wash it with deionized water for 5min;

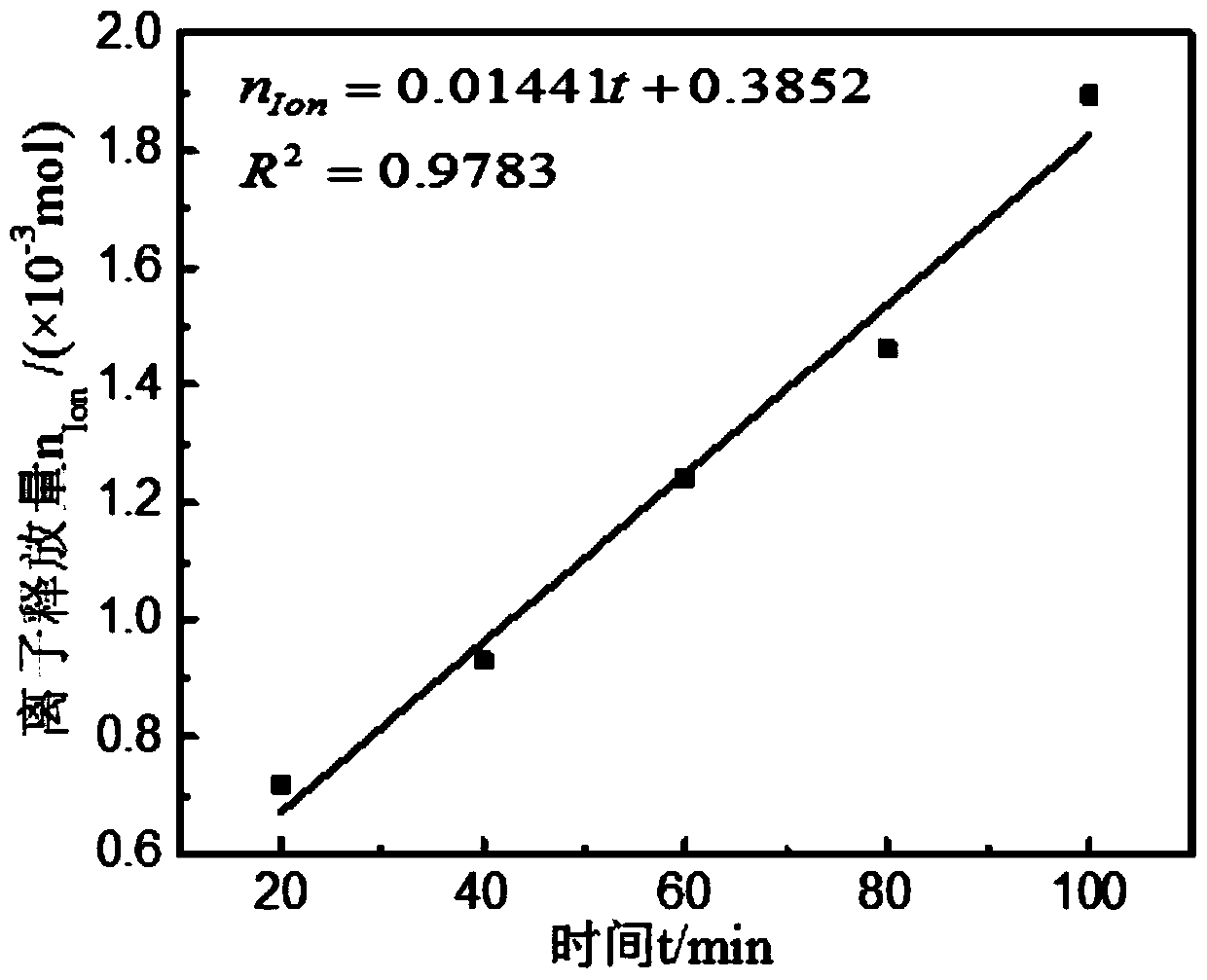

[0045] Take 10mL of 12.7mol / L concentrated hydrochloric acid and dilute it to 10 times the concentration, put the cleaned aggregate coated with cement emulsified asphalt into it for erosion, take 10mL of the erosion solution every 20min, and then dilute it 10 times; take 20mL of the dilution In the Erlenmeyer flask, add 2mL of triethanolamine solution, then add 10mL of NH with pH=10 3 -NH 4 Cl buffer solution, and the...

Embodiment 2

[0053] Measured A, B, C, D (particle size 9.5mm-13.2mm) four kinds of RAP with different shape indexes adhered to cement emulsified asphalt mortar and eroded in acid solution for 20min to release k (k is the unit mass of cement emulsified asphalt The amount of substance of the dissolved matter) value size:

[0054] Wash the four kinds of RAP aggregates separately, dry them at 50-60°C for 1.5h and weigh them. Use a digital camera to take pictures of the three vertical directions of the RAP aggregates, and collect photos of each aggregate under the same parameters. Such as image 3 As shown, IPP software is used to automatically analyze the projected area and perimeter of each picture aggregate, and the shape index S of the projected surface is calculated using formula (3).

[0055]

[0056] where SF is the shape index; l is the projected perimeter; A is the projected area. (Note: The calculation uses photo pixel units)

[0057] After carrying out the adhesion test of the ...

Embodiment 3

[0064] Cement, emulsified asphalt, limestone mineral aggregates and other materials are selected, and the continuous dense graded mixture is selected to make standard Marshall specimens in accordance with the requirements of the "Test Regulations for Asphalt and Asphalt Mixtures" (JTGE20-2011).

[0065] in:

[0066] The amount of cement in the Marshall test piece of group A is 2%, and the amount of emulsified asphalt is 7%;

[0067] The amount of cement in the Marshall specimens of group B is 2%, and the amount of emulsified asphalt is 8%;

[0068] The amount of cement in the Marshall specimens of group C is 2%, and the amount of emulsified asphalt is 9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com