VCM (Voice Coil Motor) testing mechanism, testing system comprising VCM testing mechanism as well as testing method

A testing agency and testing system technology, applied in motor generator testing and other directions, can solve the problems of uneven product quality, affecting product use, and high production costs, achieving controllability and traceability, improving work efficiency, Guaranteed effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

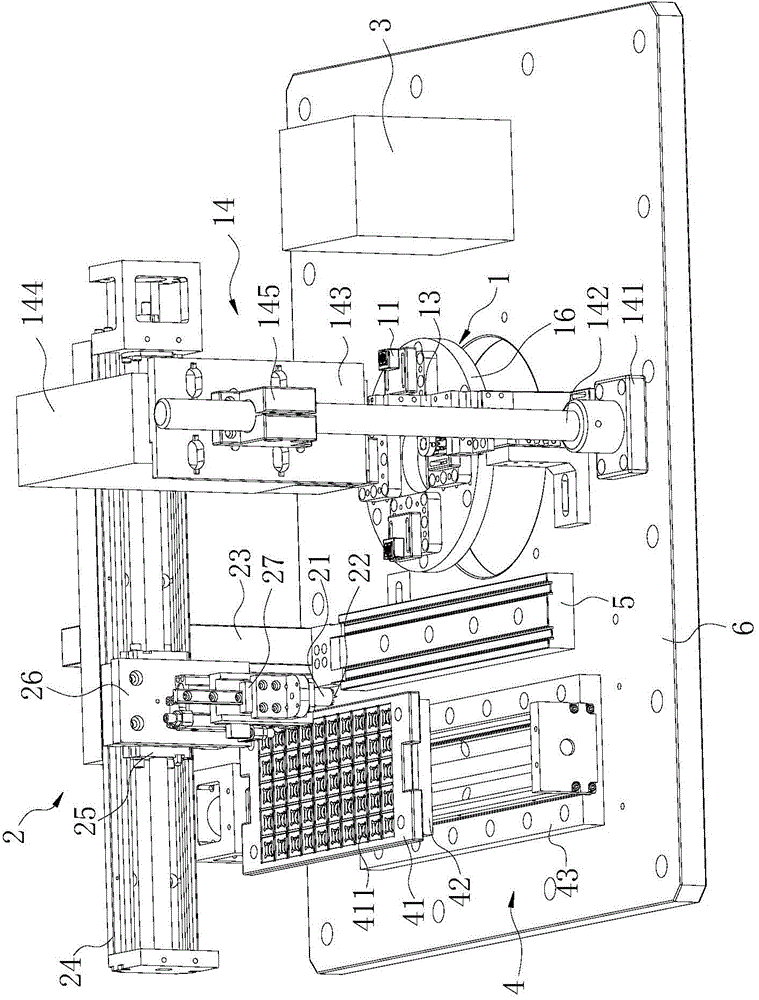

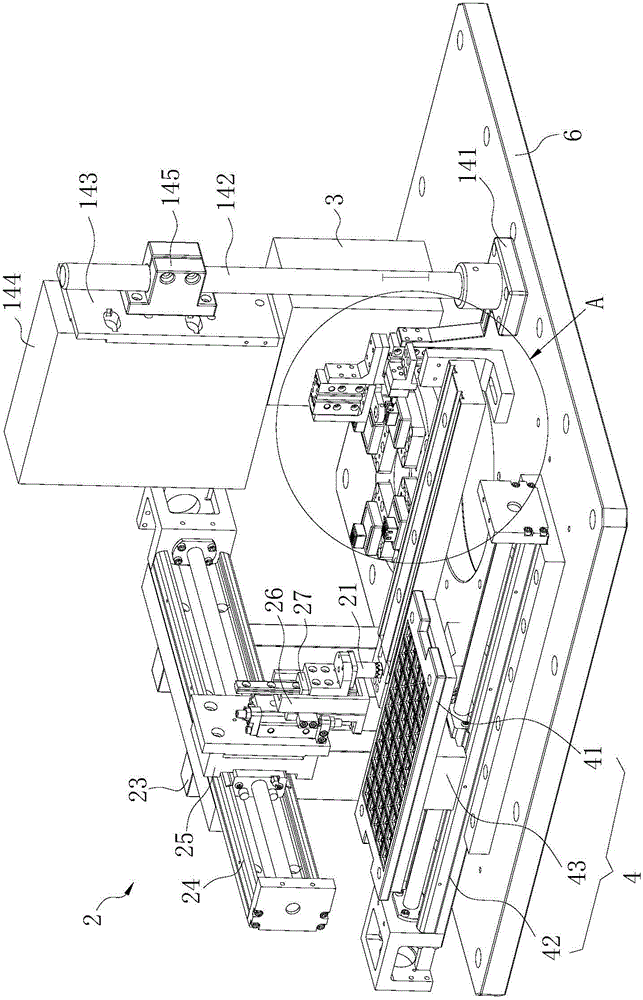

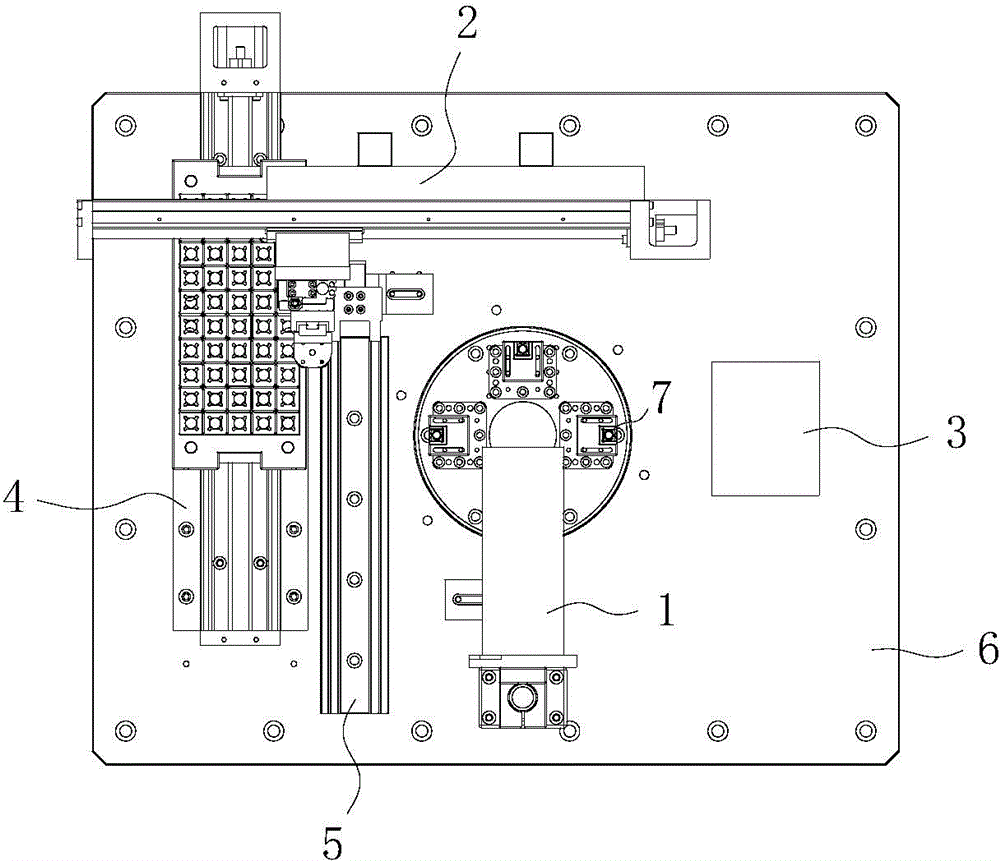

[0071] Such as Figures 1 to 4 , 8 to 11, in an embodiment of the present invention, the VCM motor testing mechanism includes a test disk assembly, a lens pick-and-place assembly 13, a sensor assembly 14, and a probe assembly 15, wherein the test disk assembly includes a test disk 16, in At least one test fixture 11 for installing the motor 7 is arranged on the test disk 16, a rotating motor is arranged at the bottom of the test disk 16, and the output shaft end of the rotating motor is connected with the center of the test disk 16 to realize the test disk by the rotating motor. 16 rotate around its center. Specifically, four test fixtures 11 are arranged on the test disk 16 , and the four test fixtures 11 are evenly distributed along the circumferential direction of the test disk 16 .

[0072] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com