Test system and test method for open-end winding permanent magnet synchronous motor

A permanent magnet synchronous motor, open winding technology, used in motor generator testing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

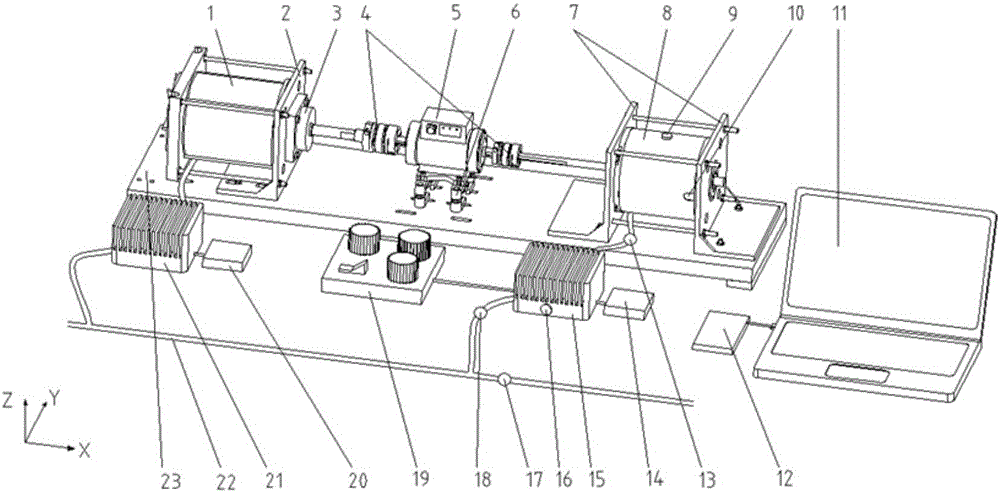

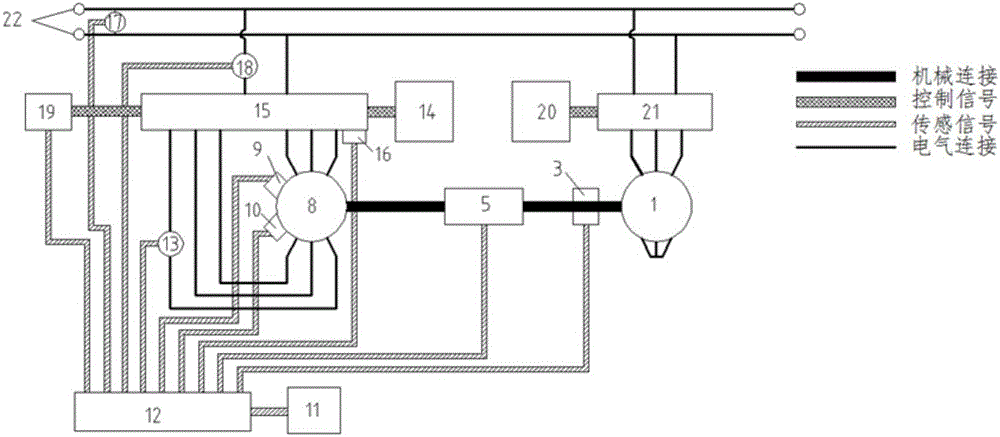

[0054] refer to figure 1 , 2 , a permanent magnet synchronous motor test system with open windings, comprising a permanent magnet synchronous load motor 1 and a tested open winding drive motor 8 arranged at both ends of a frame 23 through a load motor support 2 and a drive motor support 7 respectively, The torque sensor support 6 is arranged on the torque sensor 5 between the permanent magnet synchronous load motor 1 and the measured open winding drive motor 8. The output shaft of the winding drive motor 8 is connected to the output shaft of the permanent magnet synchronous load motor 1, the resolver 3 set on the output shaft of the permanent magnet synchronous load motor 1, the permanent magnet synchronous load motor 1 and the tested open winding drive motor 8 The load motor controller 20 connected to the load motor inverter 21 and the driver connected to the drive motor inverter 15 are respectively connected in parallel to the DC bus 22 through the load motor inverter 21 an...

Embodiment 2

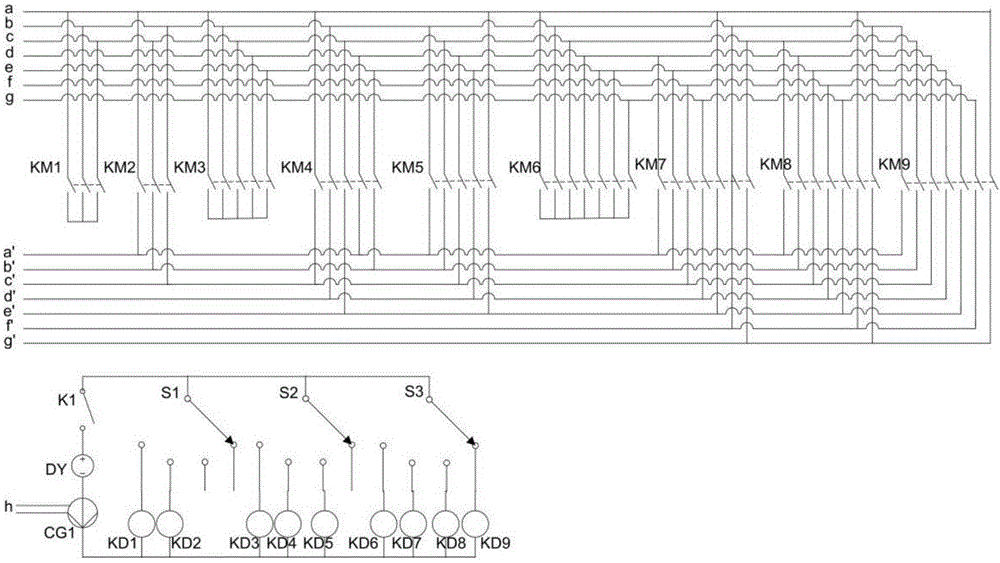

[0064] Based on the open-winding permanent magnet synchronous motor test system described in Embodiment 1, the test method for the open-winding permanent magnet synchronous motor includes working area calculation, fixed winding test and variable winding test. The specific methods are as follows:

[0065] The working area of the motor in each winding state is obtained by calculating the working area (refer to Figure 8 ):

[0066] 1) Read the number of motor phases m, the maximum power P, the maximum torque Tmax0 of the motor in the star winding state, the initial speed n0 and the maximum speed nmax0 of the constant power area;

[0067] 2) Calculate the number of winding states the motor has

[0068] 3) Let the number i of the current motor winding state take 1~(k-1) respectively, then the maximum torque of the motor in the i-th winding state is The starting speed of the constant power zone of the motor is The maximum speed of the motor is n max...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com