Low-interference food processor control method

A food processing machine and control method technology, which is applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of large circuit device parameters, high cost, and control of sacrificing product functions, so as to reduce electromagnetic Interfering, life-prolonging, reducing-requirement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] A low-interference food processing machine control method of the present invention includes a control circuit, the control circuit includes a load for food processing, a load circuit for driving the load, and a control chip, the load circuit includes a switch, the The switch is a relay, wherein the control chip detects the switch delay time of the relay, and adjusts the trigger control switch time of the relay according to the corresponding switch delay time.

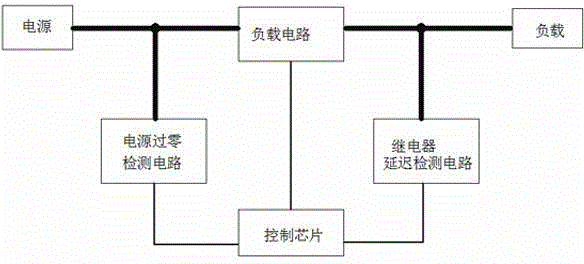

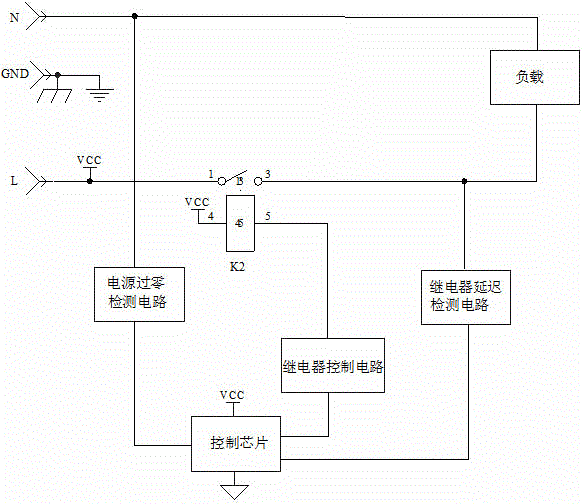

[0049] Such as figure 1 As shown, in this embodiment, the control circuit includes a power supply zero-crossing detection circuit and a relay delay detection circuit, the load is connected to the power supply through the load circuit, the control chip is connected to the load circuit, and the control chip is connected to the load circuit through the load circuit. The circuit drives the load to work, the input terminal of the power supply zero-crossing detection circuit is electrically connected between the power ...

Embodiment 2

[0076] The difference between this implementation and the above-mentioned Embodiment 1 lies in the delay time of turning on the relay and the delay time of turning off the relay in the self-checking process. In this embodiment, the food processing machine is provided with a self-inspection program for relay switch delay, wherein the self-inspection program includes a relay on-delay time detection program and a relay off-delay time detection program.

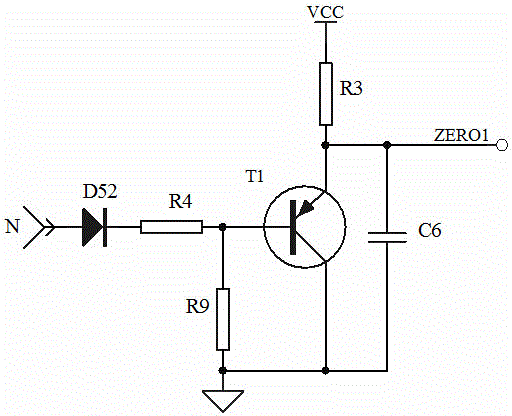

[0077] In this embodiment, after the food processing machine enters the self-inspection program, it first detects the relay turn-on delay time, and then detects the relay turn-off delay time, such as Figure 11 As shown, at this time, the control chip first detects the period T of the zero-crossing signal through the power supply zero-crossing detection circuit. After determining the zero-crossing signal period, the control chip detects the rising edge of the zero-crossing signal ZERO1 (the control chip turns on the relay and star...

Embodiment 3

[0084] The difference between this embodiment and the above embodiment is that the control chip has built-in relay reference delay times TDon and TDoff, and when the relay switching delay time detected by the control chip is greater than the reference delay time, the control chip will give an early warning prompt . The control chip sets a reference delay time according to the first detection of the relay switch delay time.

[0085] The control chip can automatically identify the contact loss of the relay by detecting Ton and Toff and comparing the time changes of TDon and TDoff. When the life of the relay expires or is about to expire, the corresponding reminder is given to remind the user to replace the relay.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com