A high-efficiency high-temperature curing drying chamber

A high-temperature curing, curing and drying technology, applied in the direction of drying gas arrangement, local stirring dryer, static material dryer, etc., can solve the problems of unstable curing and drying, affecting product quality, long working time, etc., to shorten curing and drying. time, improving product quality, and the effect of stable working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

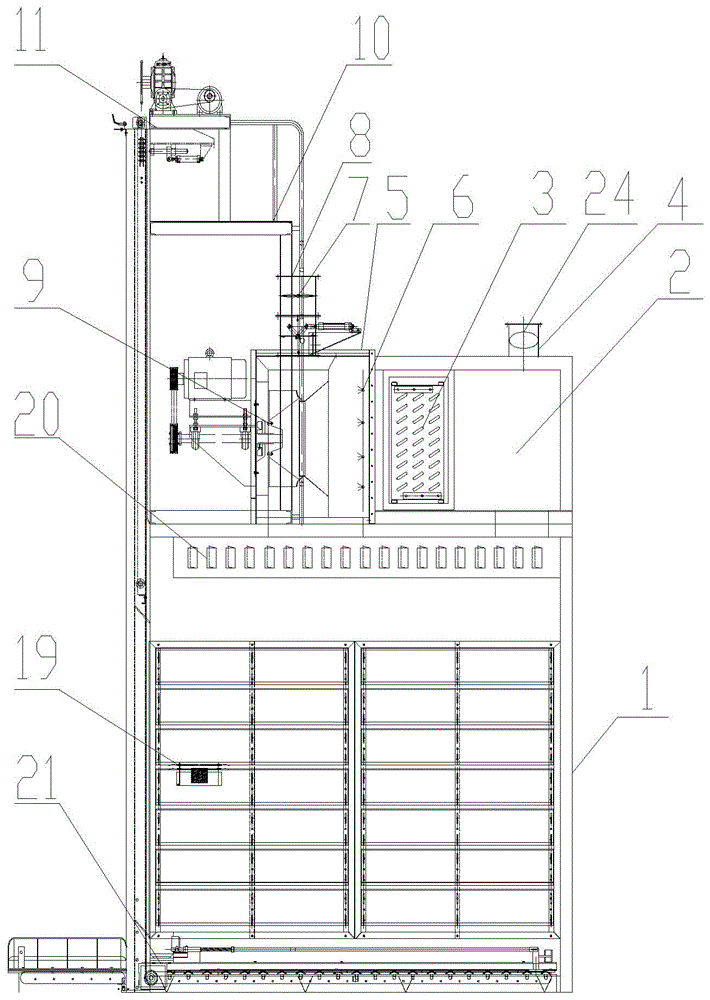

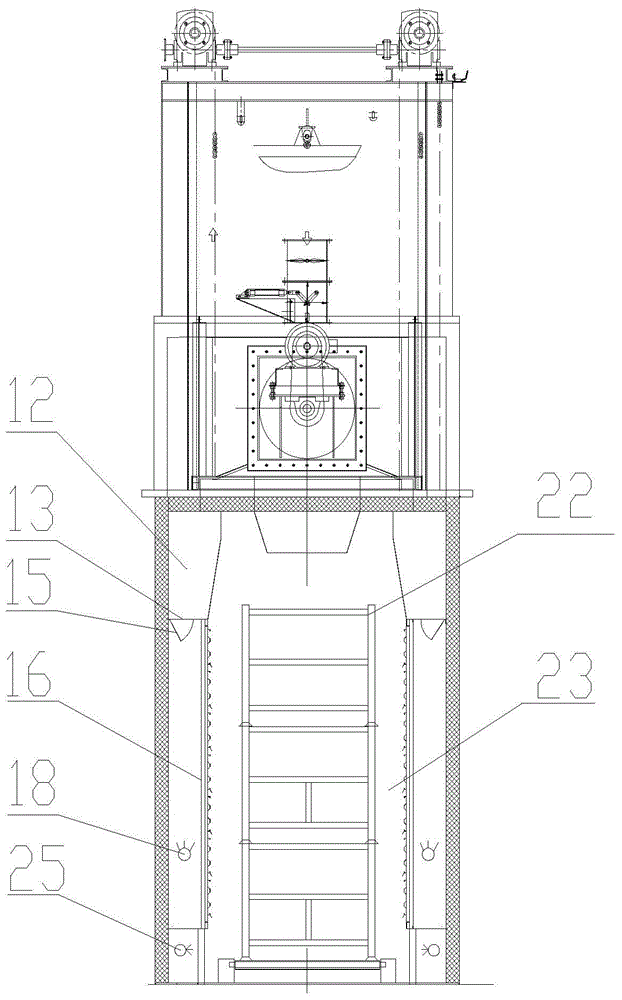

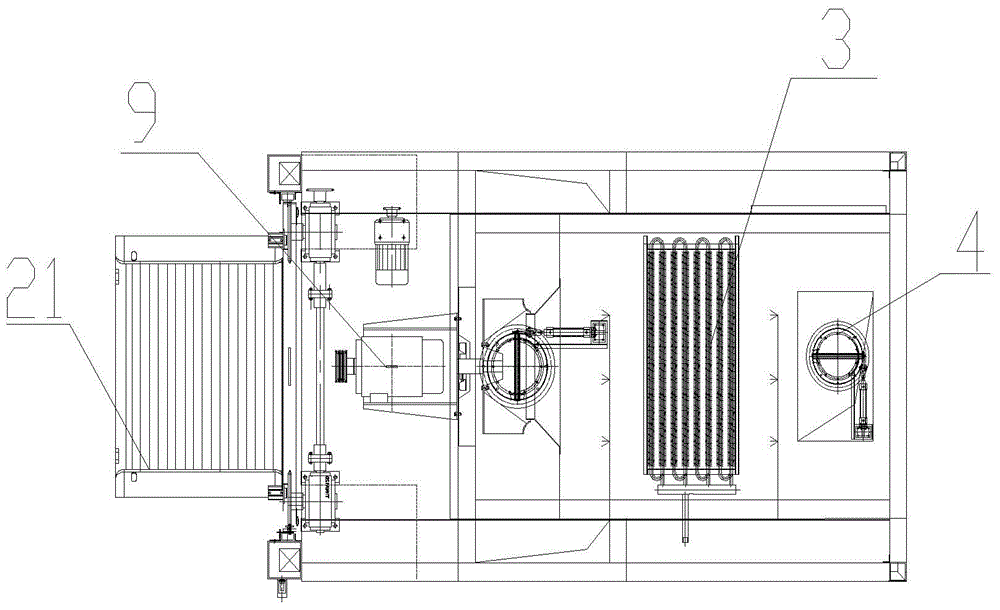

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a kind of high-efficiency high-temperature curing drying room according to the present invention includes a curing drying box 1, and an auxiliary box body 2 is provided on the outer upper side of the curing drying box 1, and a There is a heating assembly 3, an external air inlet 4 is provided on the upper part of the auxiliary box body 2, a mounting bracket 5 is provided beside the auxiliary box body 2, and a steam moisturizing pipe 6 is arranged inside the mounting bracket 5, and The top of the mounting bracket 5 is provided with a dehumidification blower 7, an external air outlet 8 is provided on the top of the dehumidification blower 7, and a circulation fan 9 is provided beside the mounting bracket ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com