Feed source with low standing-wave ratio and high cross polarization

A VSWR and source technology, applied in waveguide horns, circuits, etc., can solve the problems of complex manufacturing process, unfavorable mass production, and difficulty in meeting the requirements of low VSWR and high cross-polarization feed electrical performance indicators. The effect of good product consistency and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

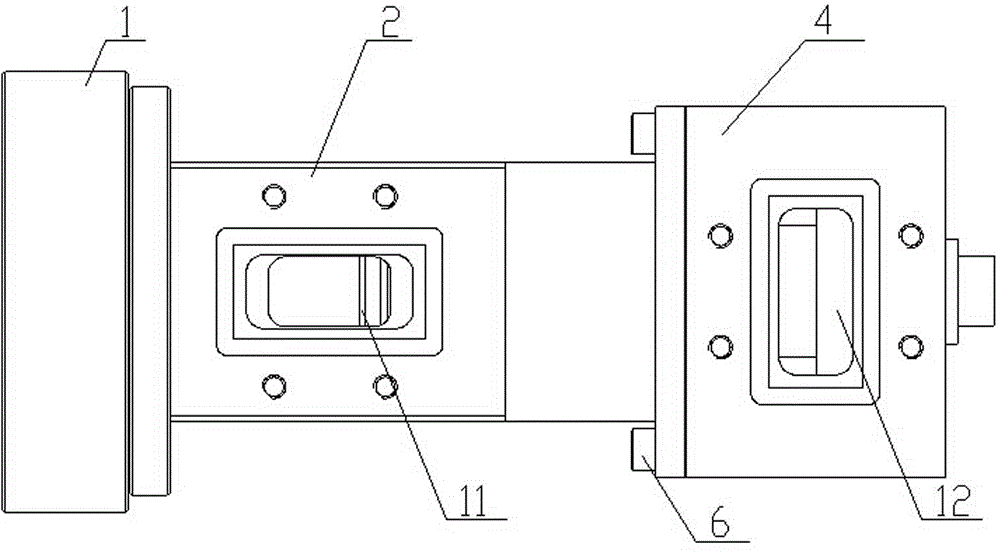

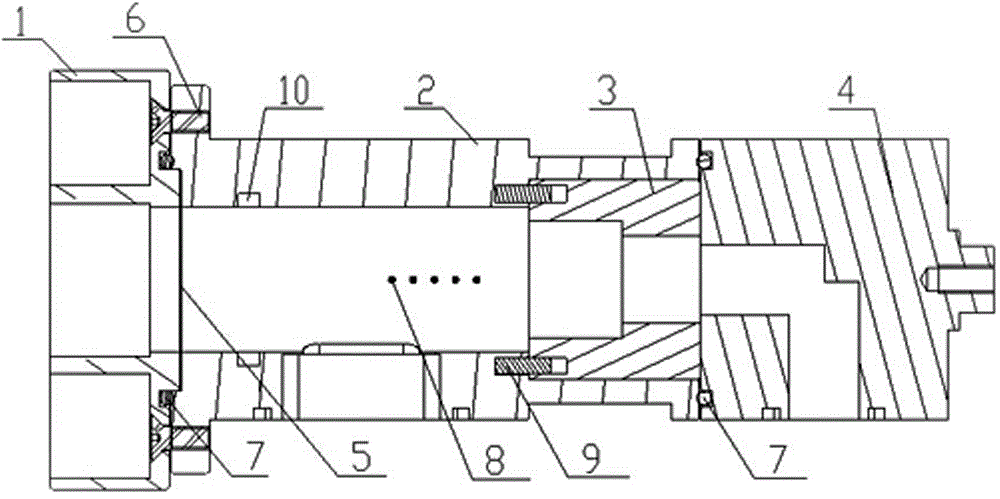

[0016] refer to Figure 1-2 , a low standing wave ratio high cross-polarized feed head, including a radiation port 1, a cavity 2 and a 90-degree converter 4; one end of the cavity 2 is connected to the radiation port 1, and the other end is connected to the 90-degree converter 4, The cavity 2 is provided with an isolation pin 8, a circular-torque converter 3 and a groove 10; the 90-degree converter 4 is connected to the circular-torque converter 3 in the cavity 2, and the cavity 2 is also provided with a first port 11, The 90-degree converter 4 is provided with a second port 12, and the first port 11 and the second port 12 are on the same side.

[0017] The radiation port 1 is provided with a sealing ring 7, the radiation port 1 and the cavity body 2 are connected by screws 6, an isolation film 5 is provided between the radiation port 1 and the cavity body 2, and the isolation film 5 is placed between the two through a sealant .

[0018] The circular moment converter 3 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com