Horizontal type beverage making machine easy to wash

A beverage machine and easy-to-clean technology, applied in beverage preparation devices, household utensils, applications, etc., can solve the problems of ineffective cleaning of the brewing chamber, inability to clean effectively, and breeding of bacteria, and achieve compact structure, easy cleaning, and avoid smelly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

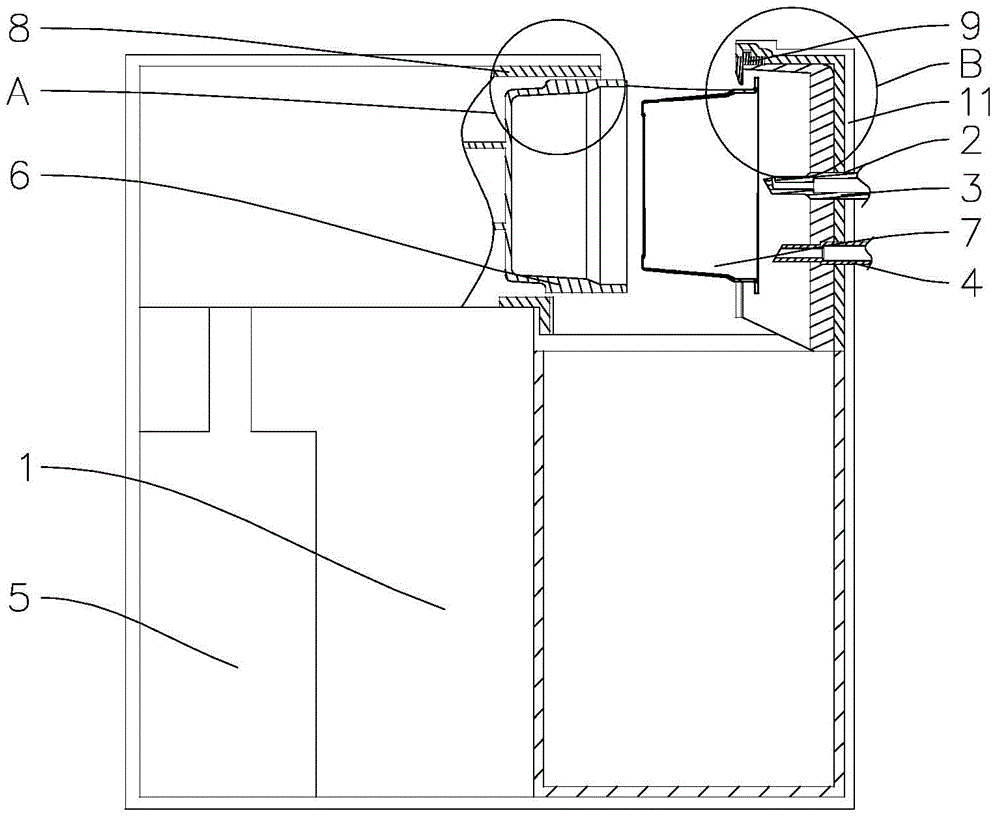

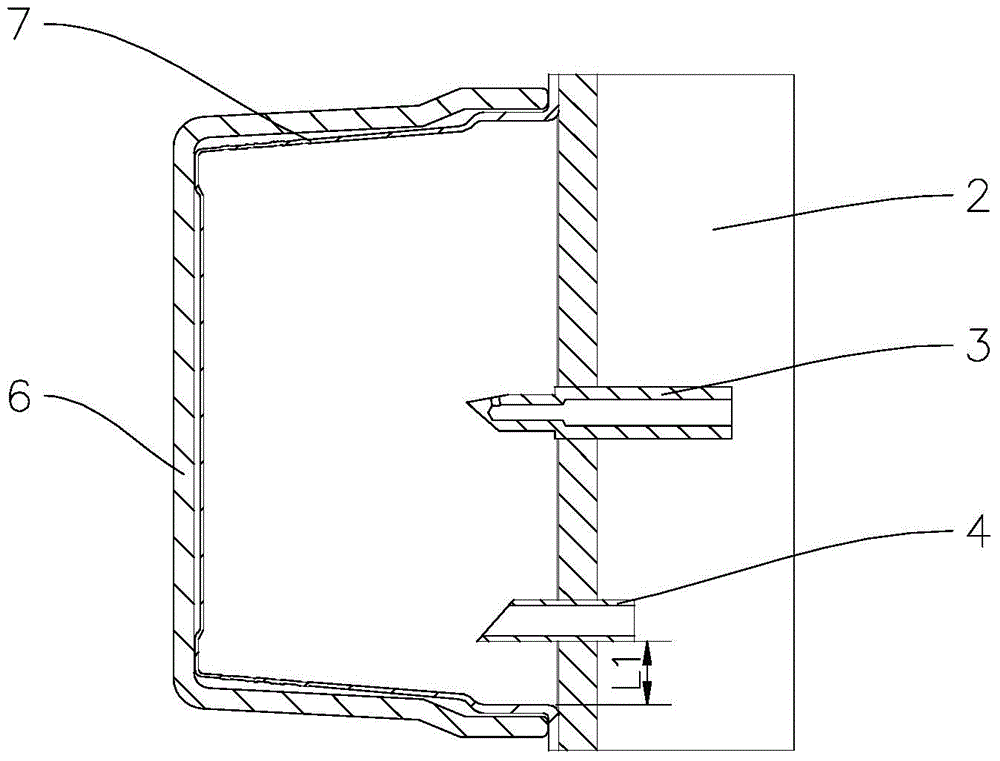

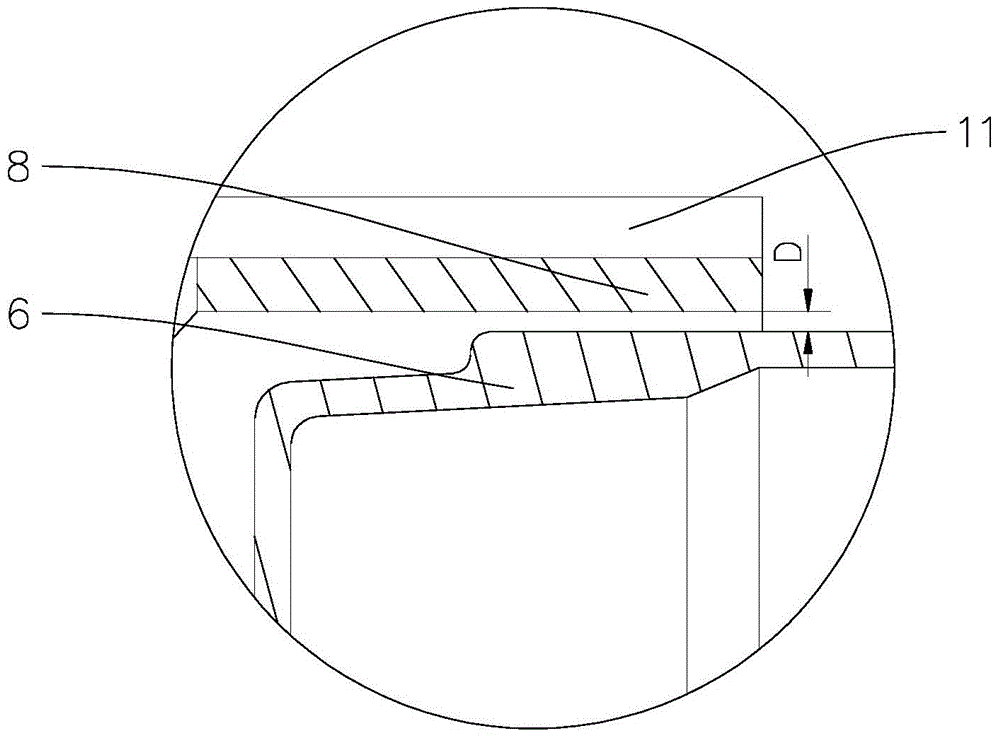

[0037] Such as figure 1 As shown in -7, the easy-to-clean horizontal brewing beverage machine of the present invention includes a machine base 1 with a brewing chamber, a brewing head 2, a water inlet needle 3, an outlet needle 4, a liquid supply mechanism 5, and a brewing cup 6. Material package7.

[0038] The liquid supply mechanism 5 provides liquid to the brewing head 2, the brewing cup 6 is used to accommodate the bag 7, one end of the brewing head 2 is connected to the liquid supply mechanism 5, and the other end provides liquid to the bag 7 Inside, the central axes of the water inlet puncture needle 3, the outlet puncture needle 4 and the material bag 7 are arranged horizontally, that is, the axis of the water inlet thorn needle 3 and the outlet puncture needle 4 coincides with or is parallel to the central axis of the brewing head 2, and the center axis of the material bag 7 The central axis is horizontal or nearly horizontal.

[0039] Such as figure 2As shown, the...

Embodiment 2

[0056] The difference between this embodiment and the embodiment is: as Figure 8 As shown, the sealing member 9 is arranged on the side wall of the brewing cup 6, the sealing member 9 is in interference fit with the inner wall of the brewing frame 8, the side wall of the brewing cup 6 is provided with a groove, and the The sealing member 9 is provided with an installation portion, and the sealing member 9 is inserted into the groove through the installation portion and fixed on the brewing cup 6 . Other structures and beneficial effects are the same as those in Embodiment 1, and will not be repeated here.

[0057] The advantage of this embodiment is that by directly setting the seal on the side wall of the brewing cup, the structure is simple, easy to install, and the sealing effect is good; The installation part is inserted into the groove and fixed through the installation part, so that the seal is installed reliably and is not easy to fall off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com