Wet-type electrostatic dust collector cathode and anode configuration structure

A technology of wet electrostatic and configuration structure, applied in the direction of electrode structure, external electrostatic separator, electrostatic separation, etc., can solve the problems of corrosion, burning through the plate, and many discharge cusps, and achieve good corrosion resistance and corona inception voltage Low, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

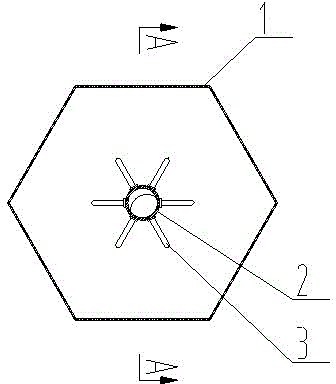

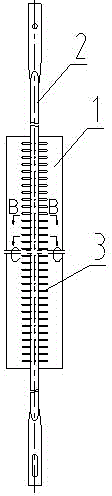

[0025] Such as Figure 1-Figure 6 As shown, the cathode and anode configuration structure of the wet electrostatic precipitator of the present invention includes a cathode 2 and an anode 1. The cathode is installed on the cathode frame, the anode 1 is installed on the anode frame, and the anode 1 is a regular hexagonal cylinder; The cathode is a cathode 2 with a discharge needle 3. The discharge needles 3 are arranged in layers on the cathode 2, with three evenly distributed in each layer, the dislocation angle between adjacent layers is 60°, and the layer spacing is 50mm (25-100mm is acceptable) The discharge needle 3 is vertically connected to the cathode 2, and each discharge needle 3 points to the cylindrical corner of the positive six sides of the anode 1, which is similar to the pole matching structure of the fishbone-shaped six-needle cathode 2 and the hexagonal cylindrical anode 1, The electric field intensity in the space between the two is improved and the anode surfac...

Embodiment 2

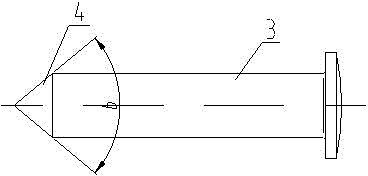

[0033] A 2*1000MW coal-fired thermal power unit in an eastern coastal area added a wet electrostatic precipitator after the wet FGD system to remove the fine dust, gypsum and acid mist entrained in the flue gas. The coal-burning condition of this unit is good, and the dust content at the inlet of wet removal is ≤20mg / Nm 3 , The droplet concentration is less than ≤40mg / Nm 3 ,Required that the dust content of the wet removal outlet ≤ 5mg / Nm 3 , The droplet concentration is less than ≤20mg / Nm 3 . In this project, the anode 1 adopts the anode 1 tube bundle assembly with an inscribed circle of φ300mm, the tube length is 5m, the cathode adopts φ15mm TA2 material wire, the cathode 2 is 6.1m long; the length of the discharge needle 3 is 10mm, the diameter is 3 mm, and the needle tip 4 The angle is 90°, and the interlayer spacing of the discharge needle 3 is 60mm. The measured dust content of the wet removal outlet is 3-4mg / Nm 3 , The droplet concentration is 16-18mg / Nm 3 .

Embodiment 3

[0035] A certain northern 2*300MW unit added a wet electrostatic precipitator after the wet FGD system. The environmental protection facilities behind the boiler are in general operation, the coal quality conditions are not good, and the dust content at the inlet of wet removal is ≤100mg / Nm 3 , The droplet concentration is less than ≤75mg / Nm 3 ,Required that the dust content of the wet removal outlet ≤25mg / Nm 3 , The droplet concentration is less than ≤20mg / Nm 3 . In this project, the anode 1 also uses the anode 1 tube bundle assembly with an inscribed circle of φ300mm, the tube length is 4.5m, the cathode is made of TA2 material with φ15mm, the cathode 2 is 5.5m long; the length of the discharge needle 3 is 12mm, The diameter is 3 mm, the angle of the needle tip 4 is 80°, and the layer spacing of the discharge needle 3 is 60 mm. . The measured dust content of the wet removal outlet is 18-22mg / Nm 3 , The droplet concentration is 16-18mg / Nm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com