Sprue cup device and pouring method for iron mold sand-covered casting

A technology of sand-covered iron mold casting and sprue cups, which is applied to casting molding equipment, molds, cores, etc., to achieve the effects of saving production costs, convenient production and operation, and good slag blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0021] Example.

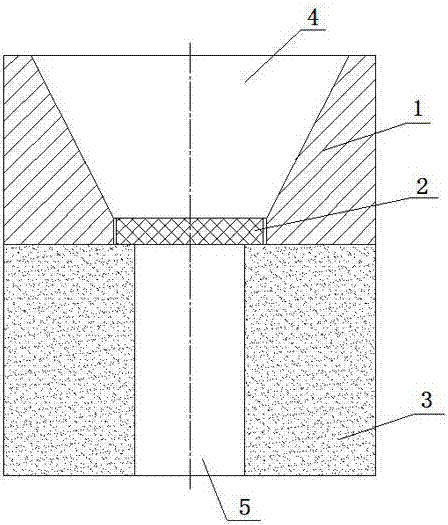

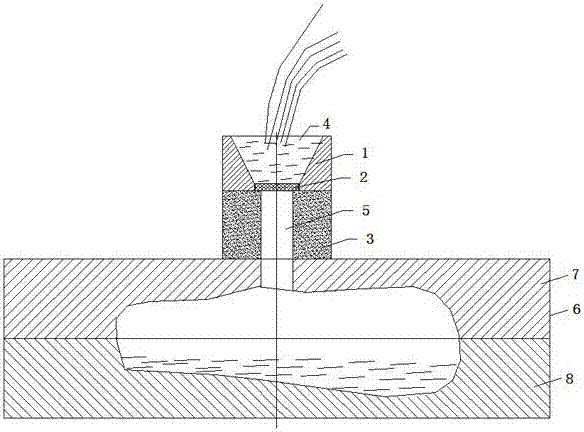

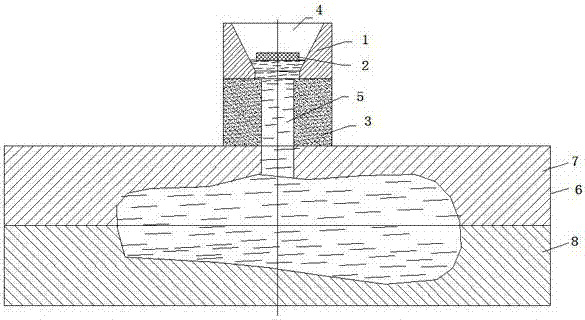

[0022] see Figure 1 to Figure 5 In this embodiment, the sprue cup device for iron mold sand-covered casting mainly includes the sprue cup upper iron mold 1, the sprue ceramic filter screen 2 and the sprue cup resin sand mold 3.

[0023] The sprue cup upper iron mold 1 in this embodiment is a trumpet type 4, the sprue cup resin sand mold 3 and the sprue cup upper iron mold 1 cooperate with each other, and the sprue cup upper iron mold 1 is located above the sprue cup resin sand mold 3 , The gate ceramic filter screen 2 is arranged in the iron mold 1 on the upper part of the gate cup.

[0024] The material of the iron mold 1 on the upper part of the sprue cup in this embodiment is gray cast iron, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com