Processing method of screw machine cover

A processing method and screw machine technology, which are applied in the field of screw machine cover processing, can solve the problems that the screw blades cannot be well protected, the cover has poor pressure bearing capacity, and the service life of the screw machine is shortened, so as to save processing time and strengthen mechanical strength. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0026] In the present invention, in the absence of a contrary description, the orientation words included in the term, such as "inside and outside", only represent the orientation of the term in the normal use state, or the common name understood by those skilled in the art, and should not be viewed as a limitation of this term.

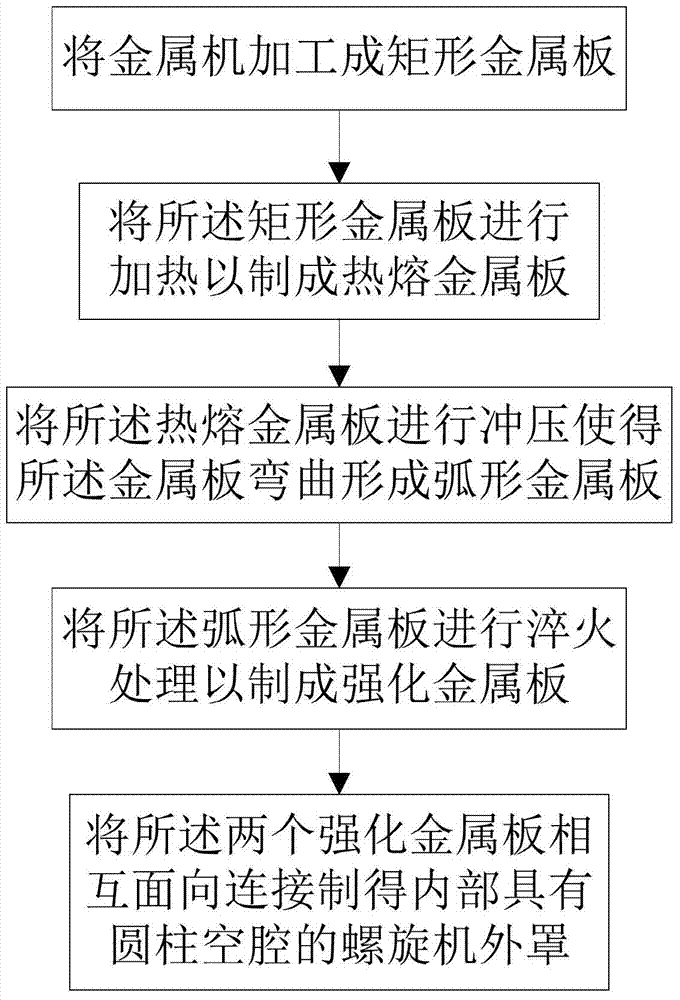

[0027] see figure 1 , the invention provides a method for processing a screw machine cover, comprising:

[0028] (1) Metal machining into rectangular metal plates;

[0029] (2) heating the rectangular metal plate to make a hot-melt metal plate;

[0030] (3) Stamping the hot-melt metal plate so that the metal plate is bent to form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com