Nylon enameled wire

A nylon enamel and covered wire technology, applied in the field of enameled wire, can solve the problems of difficult to adapt to the use environment of high temperature resistant products, easy to form oxidation spots, low temperature resistance grade of paint, etc., and achieve good mechanical strength, softening and aging performance of paint film. Good, easy to color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

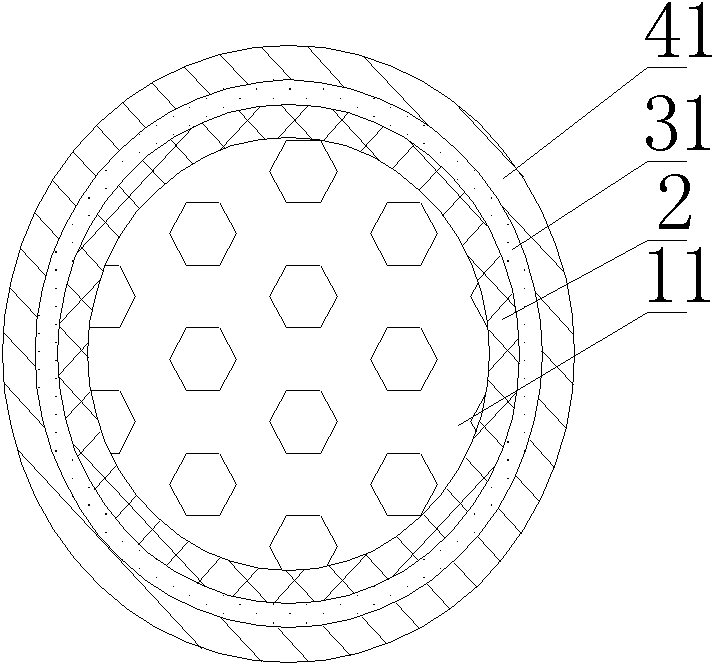

[0027] Such as figure 2 A nylon enameled wire shown includes a copper-clad aluminum alloy wire core 11, the outer surface of the copper-clad aluminum alloy wire core 11 is coated with a nylon surface layer 2, the nylon surface layer 2 is coated with a tin-plated layer 31, and the tin-plated layer 31 is coated with polyurethane paint layer 41.

Embodiment 2

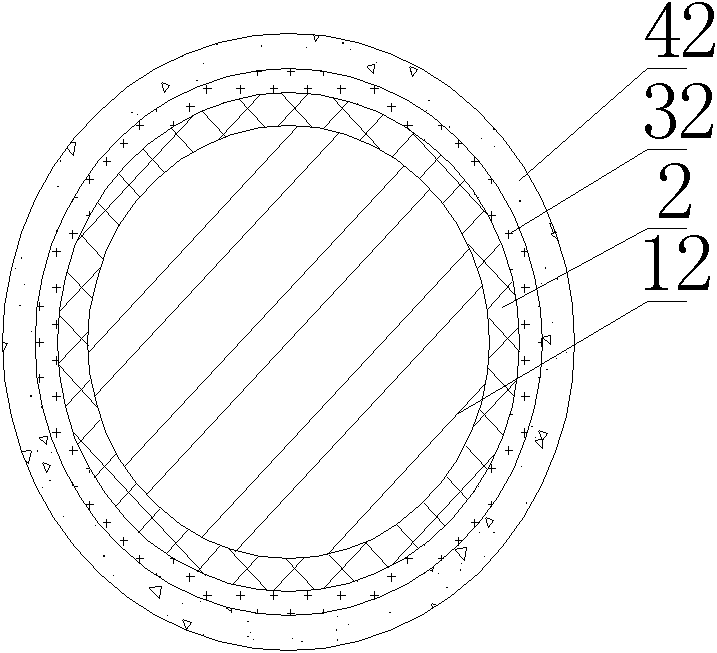

[0029] Such as image 3 A kind of nylon enameled wire shown comprises aluminum wire core 12, and the outer surface of aluminum wire core 12 is coated with nylon surface layer 2, and nylon surface layer 2 is coated with silver-plated layer 32, and silver-plated layer 32 is coated with poly Ester paint layer 42 .

Embodiment 3

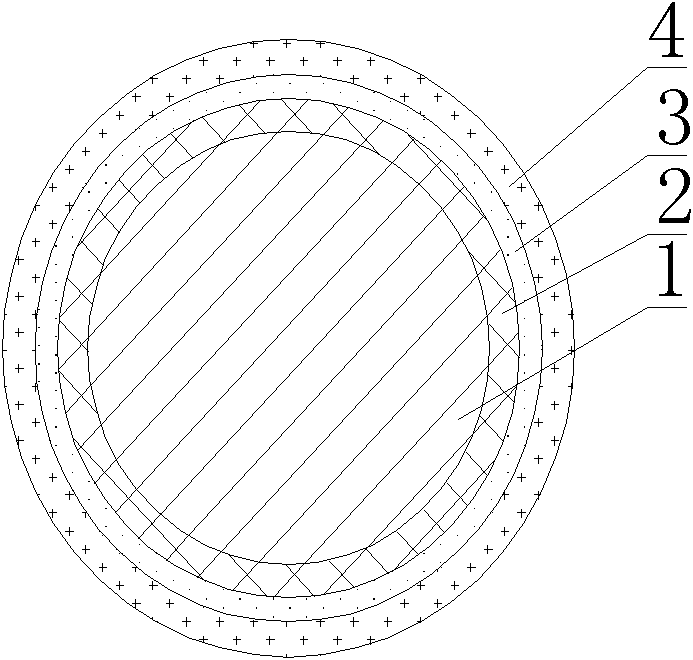

[0031] Such as Figure 4 The illustrated nylon enameled wire comprises a copper-clad aluminum-magnesium alloy wire core 13, the outer surface of the copper-clad aluminum-magnesium alloy wire core 13 is coated with a nylon surface layer 2, and the nylon surface layer 2 is coated with a tin-plated layer 31. The tin layer 31 is coated with a polyesterimide paint layer 43 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com