Lacquered wire

A technology of enameled wire and varnish layer, applied in the field of enameled wire, can solve the problems of not having high temperature resistance, corrosion resistance, oxidation of metal wire core, affecting quality, etc., and achieve the effect of good mechanical strength, easy coloring and strong heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

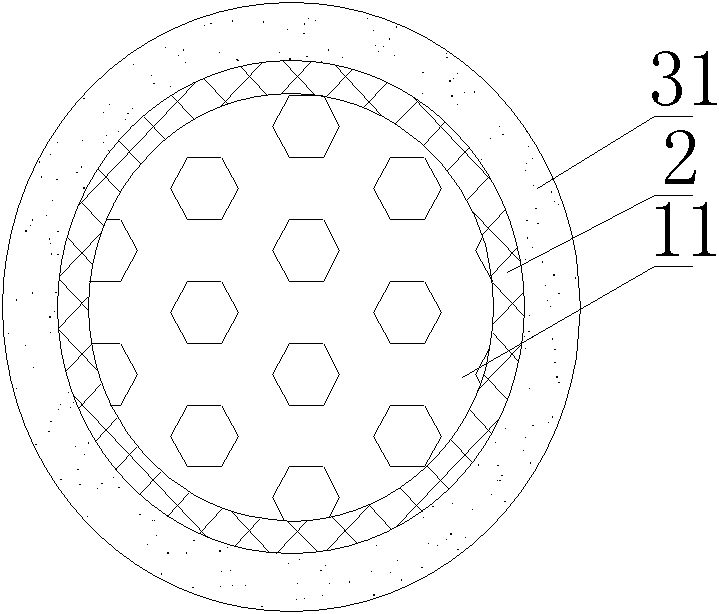

[0027] Such as figure 2 The enameled wire shown includes a copper wire core 11, the outer surface of the copper wire core 11 is coated with a nylon surface layer 2, and the nylon surface layer 2 is coated with a polyurethane paint layer 31.

Embodiment 2

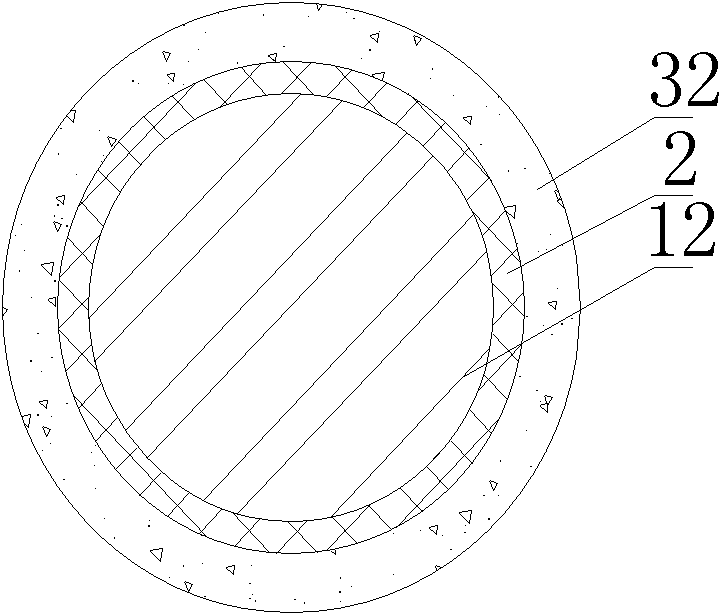

[0029] Such as image 3 The enameled wire shown includes a copper-clad aluminum alloy wire core 12 , the outer surface of the copper-clad aluminum alloy wire core 12 is coated with a nylon surface layer 2 , and a polyester paint layer 32 is coated on the nylon surface layer 2 .

Embodiment 3

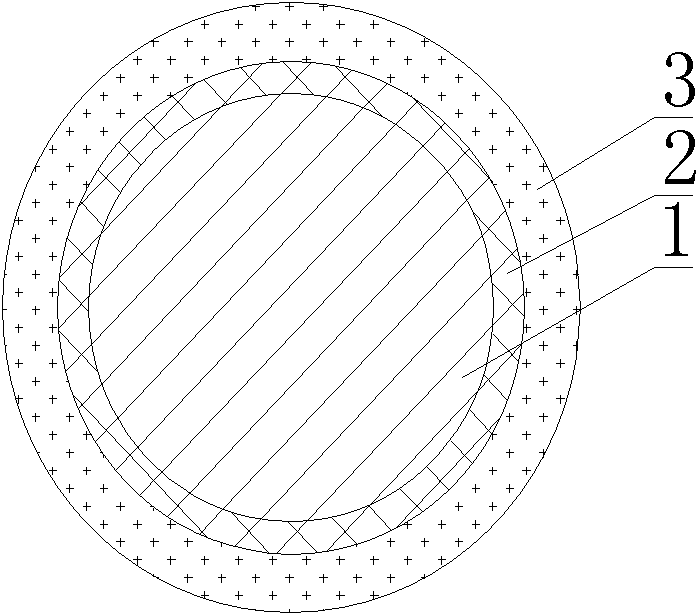

[0031] Such as Figure 4 The enameled wire shown includes an aluminum wire core 13, the outer surface of the aluminum wire core 13 is coated with a nylon surface layer 2, and the nylon surface layer 2 is coated with a polyesterimide paint layer 33.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com