Preparation method for aluminum enamel covered wire

A technology of aluminum enameled wire and production method, which is applied in cable/conductor manufacturing, organic insulators, conductors and other directions, can solve the problems affecting product quality and yield, weak adhesion, low yield, etc. The effect of weak paint film adhesion and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

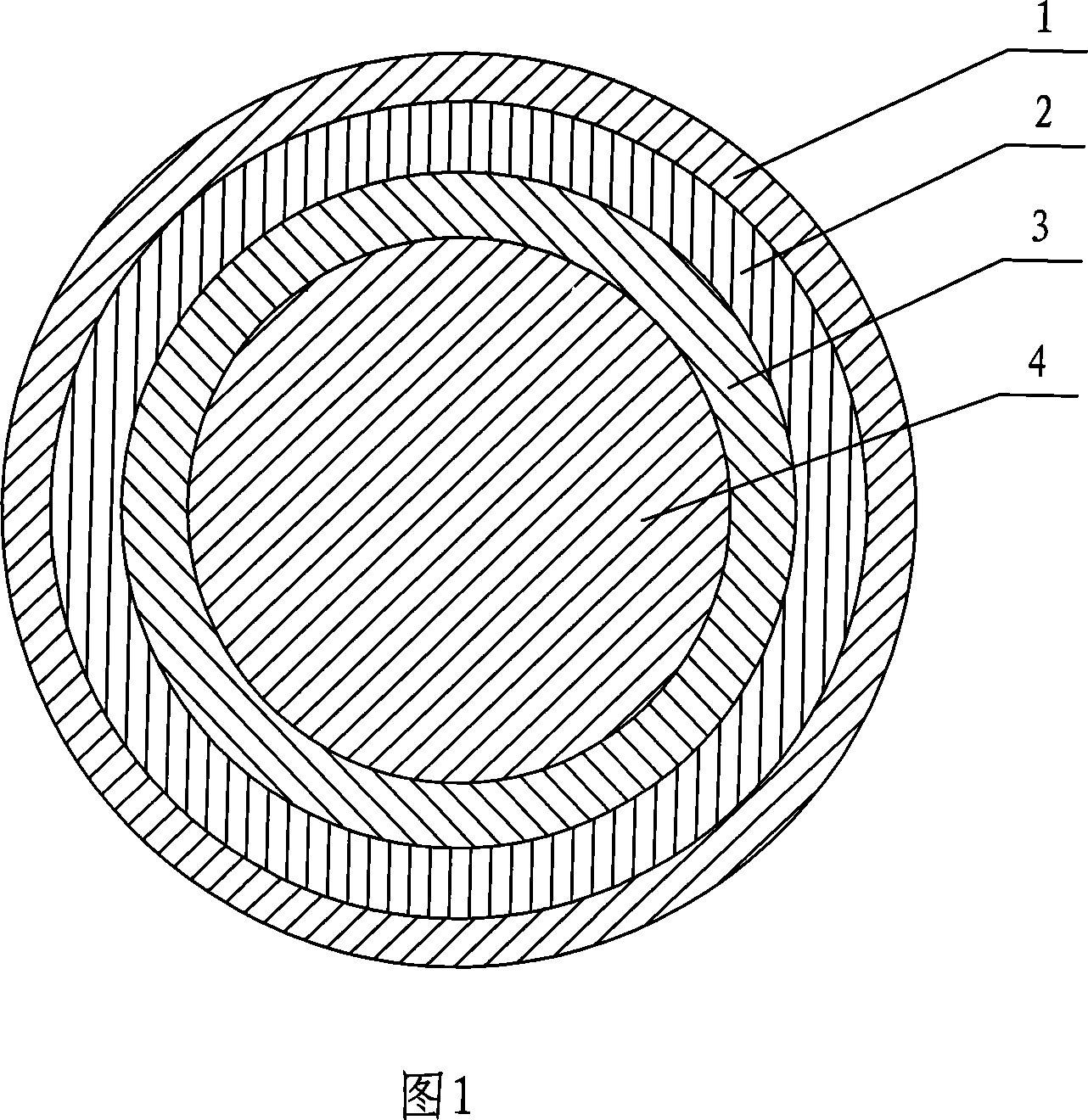

[0027] Referring to Fig. 1, an aluminum enameled wire comprises an aluminum round conductor 4, and the surface of the aluminum round conductor is provided with a primer layer 3, an intermediate layer 2 and a surface insulating layer 1 in sequence, wherein the primer layer is an epoxy resin layer, and the intermediate layer is Any one of high-temperature polyester layer, polyesterimide paint layer or modified polyester resin layer, and the surface insulation layer is polyamideimide paint layer.

[0028] During production: 1) Put the aluminum conductor on the wire drawing machine for large and medium drawing for multiple times, and then draw it into a bare aluminum round conductor of 0.700mm ~ 2.500mm. The drawing oil in the drawing process is 100% pure aluminum drawing Oil, the diameter ratio of the upper and lower stages of the drawing machine is 1:1.32...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com