Intravenous needle assembly machine

A technology for assembling machines and venous needles, which is applied in the direction of assembling machines, needles, and instruments introduced into the body, etc. It can solve the problems of complex structure, numerous operation steps, and high production costs of venous needle assembling machines, and achieve simple structure, high safety, and easy assembly. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

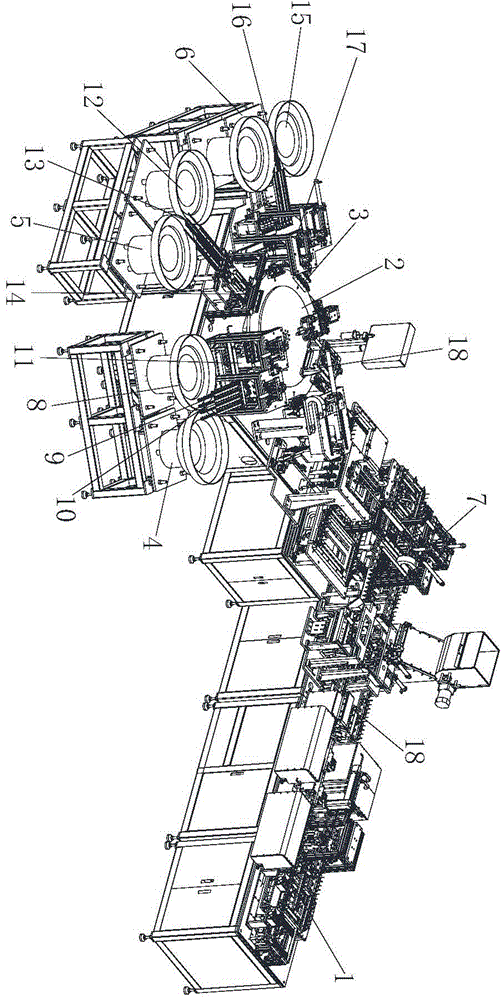

[0020] Such as figure 1 As shown, the venous needle assembly machine includes a frame 1, a turntable 2 is arranged on the frame 1, and a plurality of assembly stations 3 are arranged on the outer ring of the turntable 2, and arc-shaped distribution around one side of the turntable 2 is also arranged on the frame 1. And the corresponding components can be fed to the shell feeding mechanism 4 on the assembly station 3, the sheath feeding mechanism 5, and the needle holder feeding mechanism 6. The push flat needle seat mechanism 7 of the cover and the assembly mechanism capable of assembling the sheath and the shell, the push flat needle seat mechanism 7 and the assembly mechanism are located on the other side of the turntable 2, and the turntable 2 and the rotating disk that can drive the turntable 2 to rotate The driving mechanism is connected, and a dispensing system is also arranged on the frame 1. The shell feeding mechanism 4 loads the shell onto the assembly station 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com