Caffeoyl group-containing tannin derivative, and preparation technology and application thereof

A technology of caffeoyl group and preparation process, which is applied in the field of secondary metabolic active components and their utilization, can solve the problems of little research on secondary metabolic chemical components of Yangbi walnut leaves, and achieves simple and standardized operation method, low preparation cost and high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

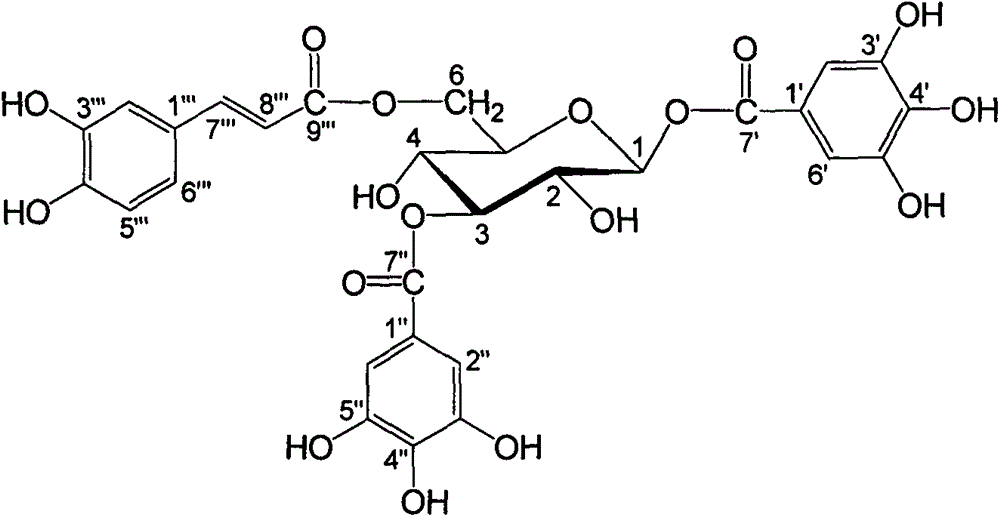

[0020] Preparation of 1,3-di-O-galloyl-6-O-caffeoyl-β-D-glucopyranose

[0021] (1) Take pulverized Yangbi walnut leaves, add 60% acetone aqueous solution at a mass ratio of 1:4, extract at room temperature for 3 times, each time for 72 hours, filter, and concentrate the filtrate under reduced pressure to 4% of the original volume. %, get crude extract;

[0022] (2) adding water with 3 times the mass of the crude extract, stirring, adding n-hexane with 2 times the mass of the crude extract to extract 4 times, separating the n-hexane layer, and concentrating the n-hexane layer under reduced pressure to obtain the n-hexane extract phase;

[0023] (3) The n-hexane extraction phase was prepared by silica gel column chromatography to obtain 1,3-di-O-galloyl-6-O-caffeoyl-β-D-glucopyranose.

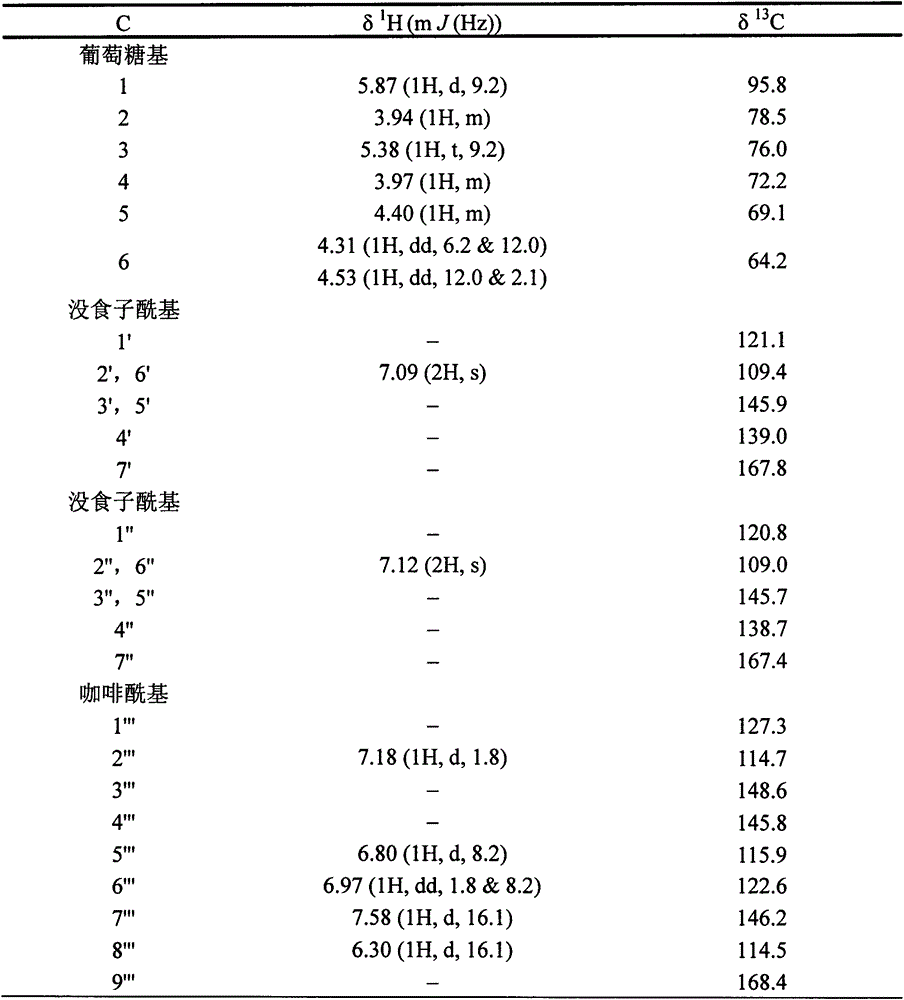

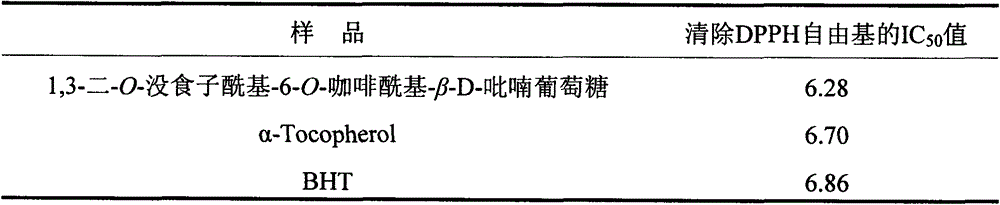

[0024] The structural identification of the compound:

[0025] The m / z[M+Na] of the compound can be known from the positive fast atom bombardment mass spectrum (Positive FAB-MS) + is 669, and ...

Embodiment 2

[0029] (1) Take pulverized Yangbi walnut leaves, add 70% acetone aqueous solution at a mass ratio of 1:5, microwave-assisted extraction for 4 times, each time for 1.5 hours, filter, and concentrate the filtrate under reduced pressure to the original volume 5%, get the crude extract;

[0030] (2) adding water with 2 times the mass of the crude extract, stirring, adding n-hexane with 3 times the mass of the crude extract to extract 3 times, separating the n-hexane layer, and concentrating the n-hexane layer under reduced pressure to obtain the n-hexane extract phase;

[0031] (3) The n-hexane extract phase was prepared by gel column chromatography to obtain 1,3-di-O-galloyl-6-O-caffeoyl-β-D-glucopyranose.

Embodiment 3

[0033] (1) Take pulverized Yangbi walnut leaves, add 80% acetone aqueous solution with a volume percentage concentration of 1:6 by mass ratio, ultrasonically assisted extraction 2 times, each time for 2 hours, filter, and the filtrate is concentrated under reduced pressure to the original volume. 8%, get the crude extract;

[0034] (2) adding water with 1.5 times the mass of the crude extract, stirring, adding n-hexane with 2 times the mass of the crude extract to extract twice, separating the n-hexane layer, and concentrating the n-hexane layer under reduced pressure to obtain the n-hexane extract phase;

[0035] (3) The n-hexane extraction phase was prepared by silica gel column chromatography and gel column chromatography to obtain 1,3-di-O-galloyl-6-O-caffeoyl-β-D-glucopyranose.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com