Method for manufacturing high-fire-retardant blended fabric

A blended fabric, high flame-retardant technology, applied in the field of preparation of high flame-retardant blended fabrics, can solve the problems of poor stability of finishing liquid, white frost phenomenon, hard hand feeling, etc., and achieve good product quality reproducibility, protection resistance Inflammability, avoiding the effect of loss of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

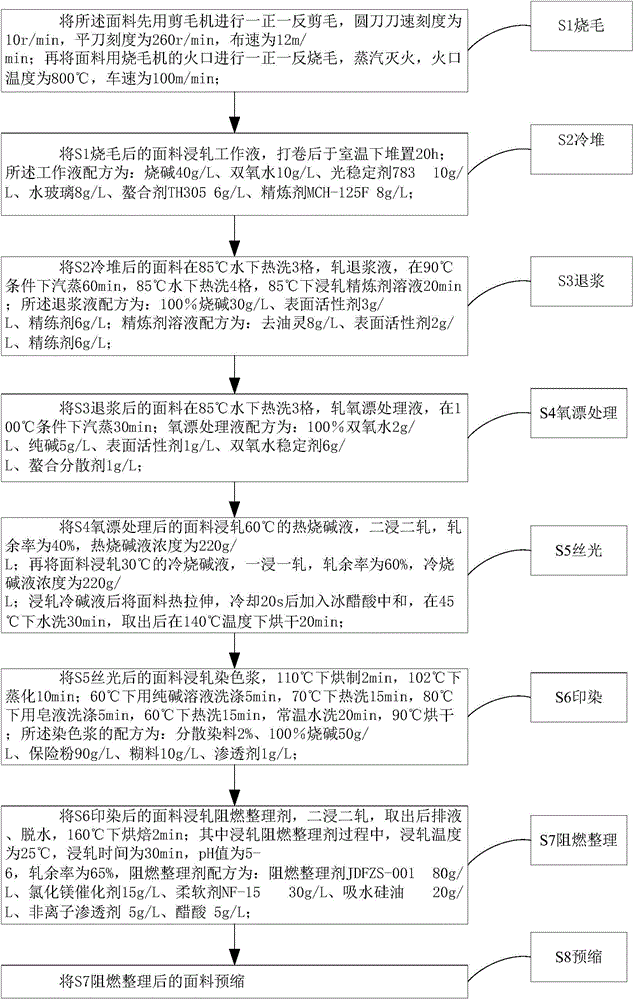

[0026] Such as figure 1 as shown, figure 1 It is a flow chart of the preparation method of a high flame-retardant blended fabric proposed by the present invention.

[0027] refer to figure 1 , a method for preparing a highly flame-resistant blended fabric, the fabric adopts a fabric with a mass percentage of 70% vinylon fiber and 30% cotton fiber blended into an 80-count yarn, and a fabric with a warp and weft density of 100 and 88; including the following step:

[0028] S1 singeing

[0029] The fabric is first sheared with a shearing machine, the speed scale of the round knife is 10r / min, the scale of the flat knife is 260r / min, and the cloth speed is 12m / min; then the fabric is singed with the burner of the singeing machine One front and one reverse singeing, steam fire extinguishing, the temperature of the burner is 800 ℃, and the speed of the vehicle is 100m / min;

[0030] S2 cold stack

[0031] The padding working solution of the fabric after S1 singeing is rolled up...

Embodiment 2

[0045] A method for preparing a highly flame-resistant blended fabric, wherein the fabric is made of 80-count yarn blended with 91% vinylon fiber and 9% cotton fiber by mass percentage, and has a warp and weft density of 100 and 88; it includes the following steps:

[0046] S1 singeing

[0047] The fabric is first sheared with a shearing machine, the speed scale of the round knife is 15r / min, the scale of the flat knife is 230r / min, and the cloth speed is 17m / min; then the fabric is singed with the burner of the singeing machine One front and one reverse singeing, steam fire extinguishing, the temperature of the burner is 600 ℃, and the speed of the vehicle is 150m / min;

[0048] S2 cold stack

[0049] Pad the fabric after S1 singeing with the working solution, and stack it at room temperature for 25 hours after rolling; the formula of the working solution is: caustic soda 35g / L, hydrogen peroxide 12g / L, light stabilizer 783 8g / L, water glass 10g / L L. Chelating agent TH305 5g...

Embodiment 3

[0063] A method for preparing a highly flame-resistant blended fabric, the fabric adopts 80 English count yarns blended with 80% vinylon fiber and 20% cotton fiber, and has a warp and weft density of 100 and 88; it includes the following steps:

[0064] S1 singeing

[0065] The fabric is first sheared with a shearing machine, the speed scale of the round knife is 12r / min, the scale of the flat knife is 240r / min, and the cloth speed is 15m / min; then the fabric is singed with the burner of the singeing machine One front and one reverse singeing, steam fire extinguishing, the temperature of the burner is 700 ℃, and the speed of the vehicle is 130m / min;

[0066] S2 cold stack

[0067] Pad the fabric after S1 singeing with the working solution, and stack it at room temperature for 23 hours after rolling; the formula of the working solution is: caustic soda 38g / L, hydrogen peroxide 11g / L, light stabilizer 783 9g / L, water glass 9g / L L. Chelating agent TH305 6g / L, refining agent MCH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com