Puncturing and compacting device for carbon fiber three-dimensional fabric forming

A technology of three-dimensional fabric and compaction device, which is applied in the directions of lamination device, lamination, needle punching machine, etc., can solve the problems of affecting the molding quality of carbon fiber three-dimensional fabric and the instability of oil cylinder accuracy, so as to reduce labor intensity and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in combination with specific embodiments.

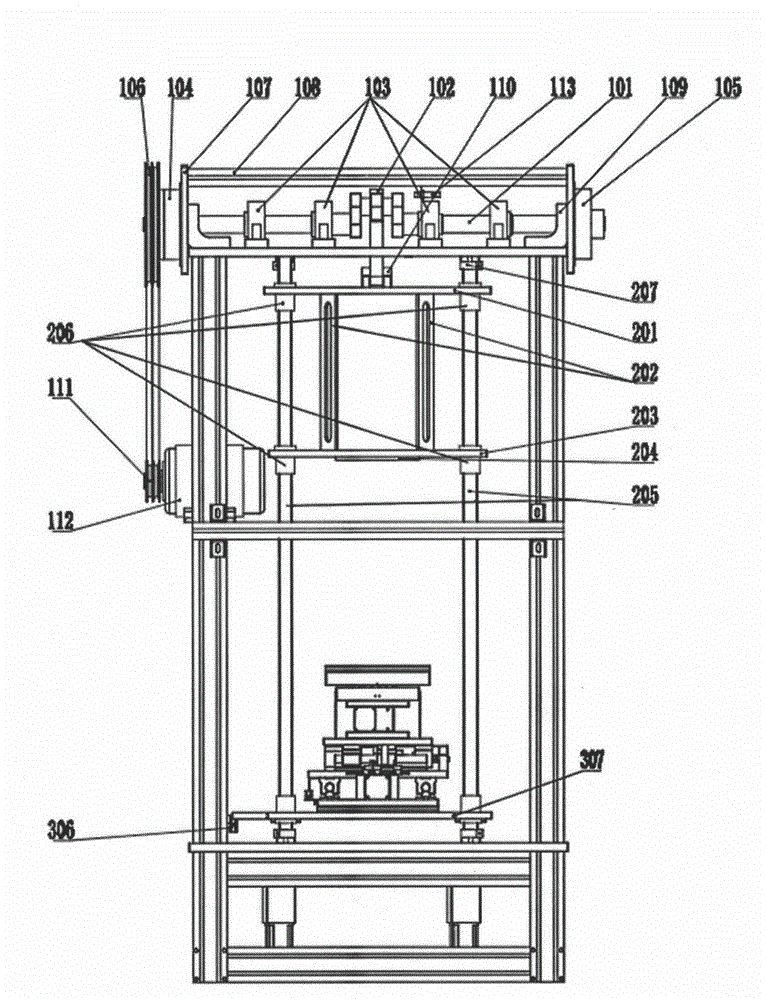

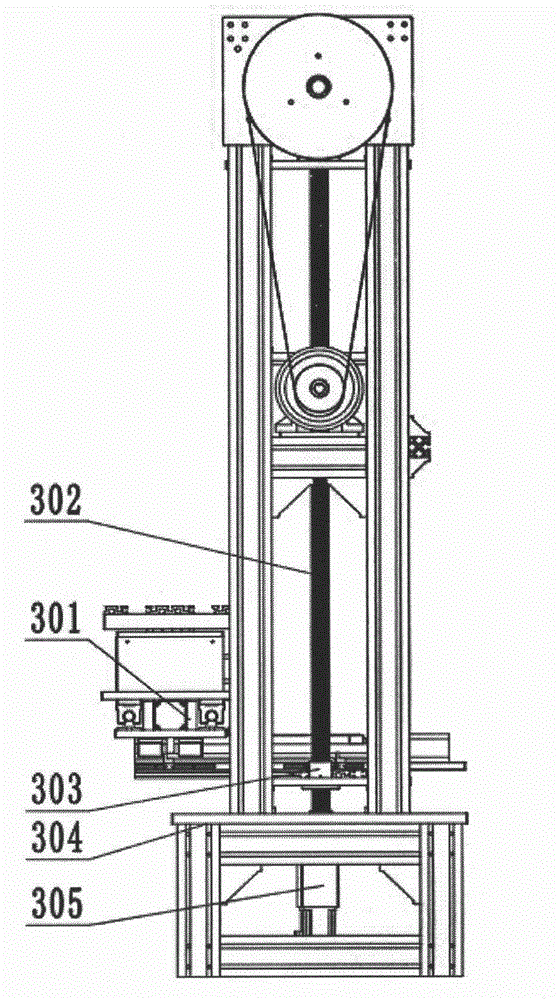

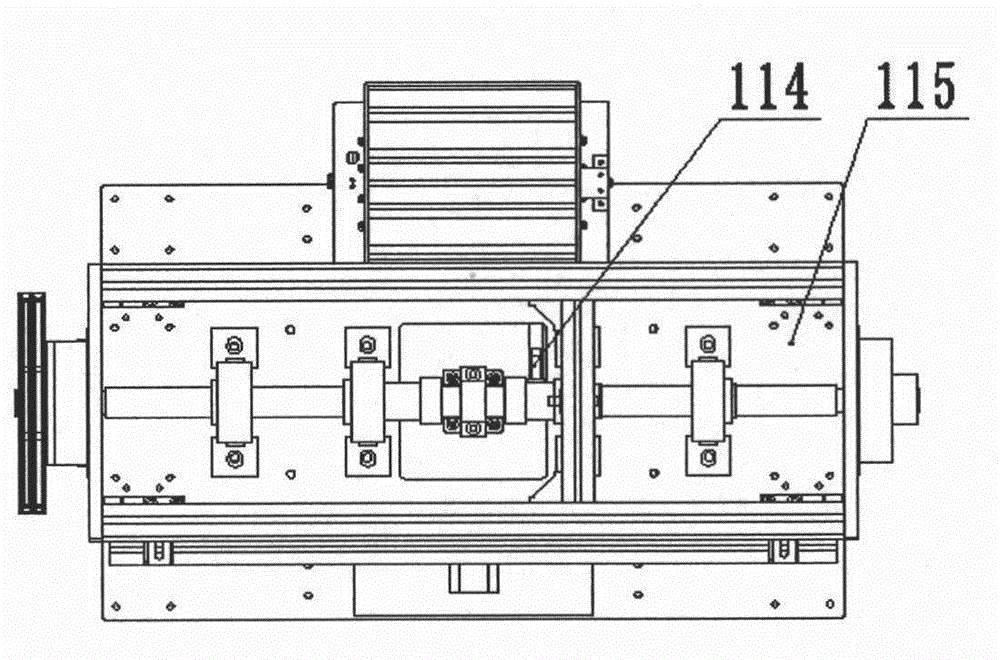

[0037] like figure 1 As shown, a puncture and compaction device for forming a carbon fiber three-dimensional fabric of the present invention includes an upper end drive device 1, and the upper end drive device 1 drives a small pulley 111 by a three-phase asynchronous motor 112 to drive a large pulley 106 through a V-belt; One end of the large pulley 106 is tightly connected to the clutch 104, and the other end is installed on the left side plate 107. The clutch 104 is keyed to one end of the crankshaft 101, and the other end of the crankshaft 101 is keyed to the brake 105; The crankshaft 101 is fixed on the upper plate 115 through four bearing housings 103; the brake is fixed on the right side plate 107; the left and right side plates 107 are connected to the upper plate 115 through support ribs 109, Two supporting aluminum profiles 108 are connected to the two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com