Stone pavement filling structure and its construction method

A construction method and technology for filling joints, which are applied in the directions of roads, roads, and pavement details, etc., can solve problems such as poor load bearing capacity and poor waterproof effect, and achieve the effect of avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

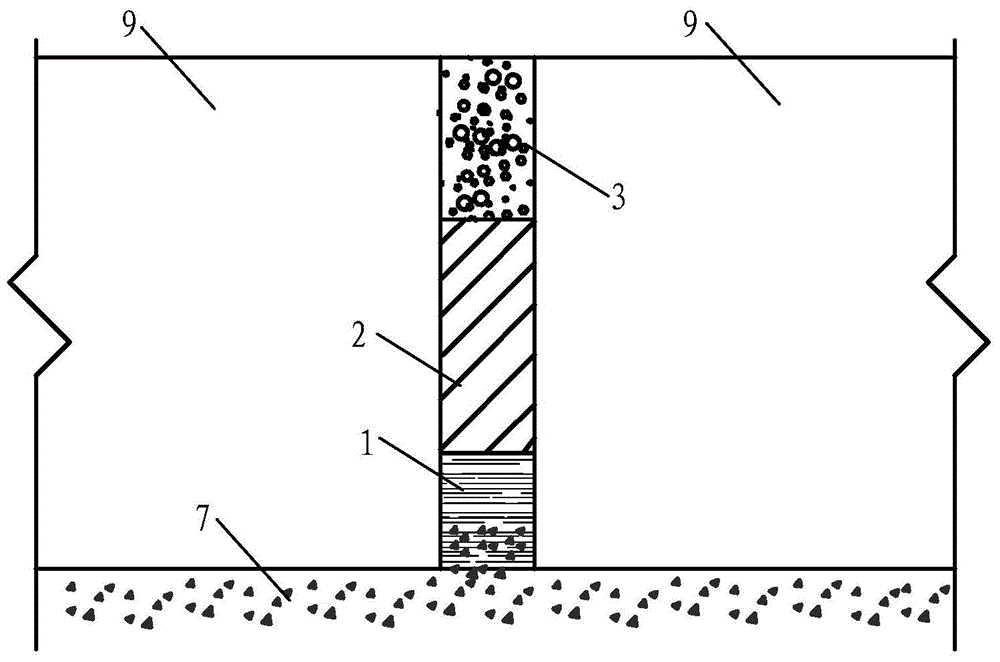

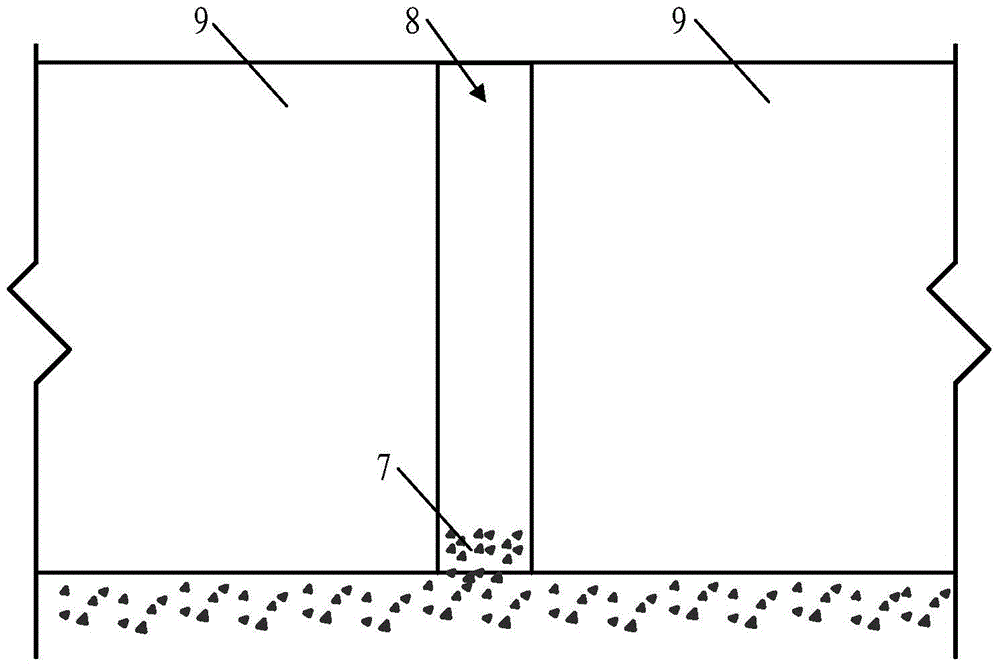

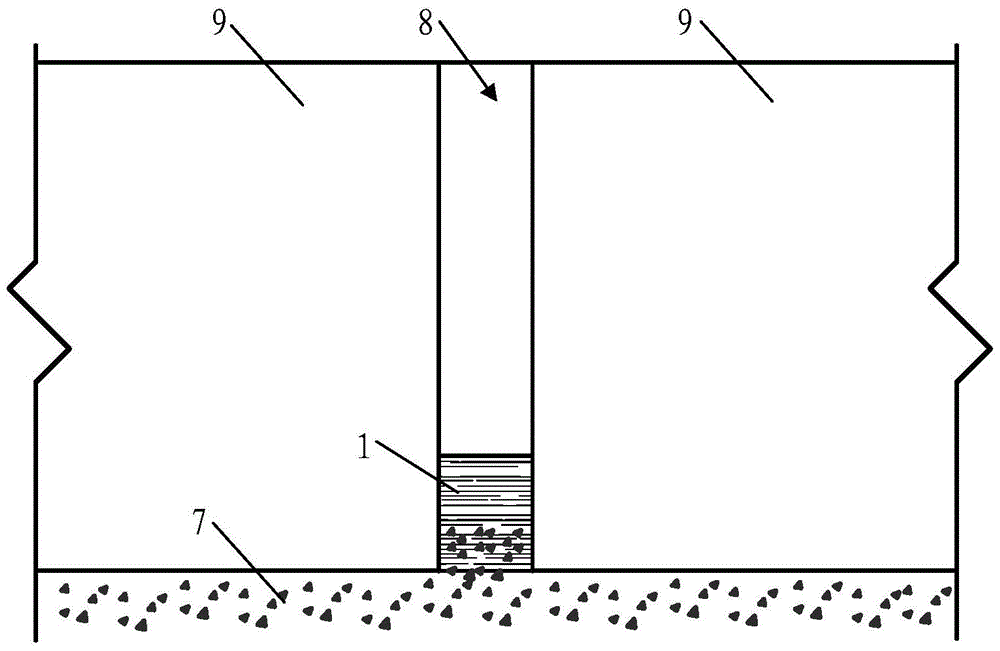

[0040] refer to figure 1 , is a schematic cross-sectional structure diagram of the stone pavement filling structure of the present invention, as figure 1 As shown, the present invention firstly provides a stone pavement filling structure. There are gaps between the stone pavement 9. The filling structure includes: a leveling layer 1 poured into the bottom of the gap; a flexible buffer layer 2 poured into the leveling layer 1 ; The filling layer 3 is poured on the flexible buffer layer 2 until the top of the gap.

[0041] Specifically, the leveling layer 1 includes cement slurry, preferably Portland cement as the cement slurry and has a thickness of 2 cm, the flexible buffer layer 2 includes asphalt, preferably quick-drying asphalt and has a thickness of 5 cm, and the filling layer 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com