A non-damage corner folding method and box-shaped metal decorative insulation board

A technology of metal decoration and heat preservation board, which is applied in the field of box-shaped metal decoration heat preservation board without damaged corners. It can solve problems such as large gaps, corrosion of metal plates, and influence on heat preservation performance, and achieve excellent anti-corrosion performance, not easy to fall off, and small gaps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

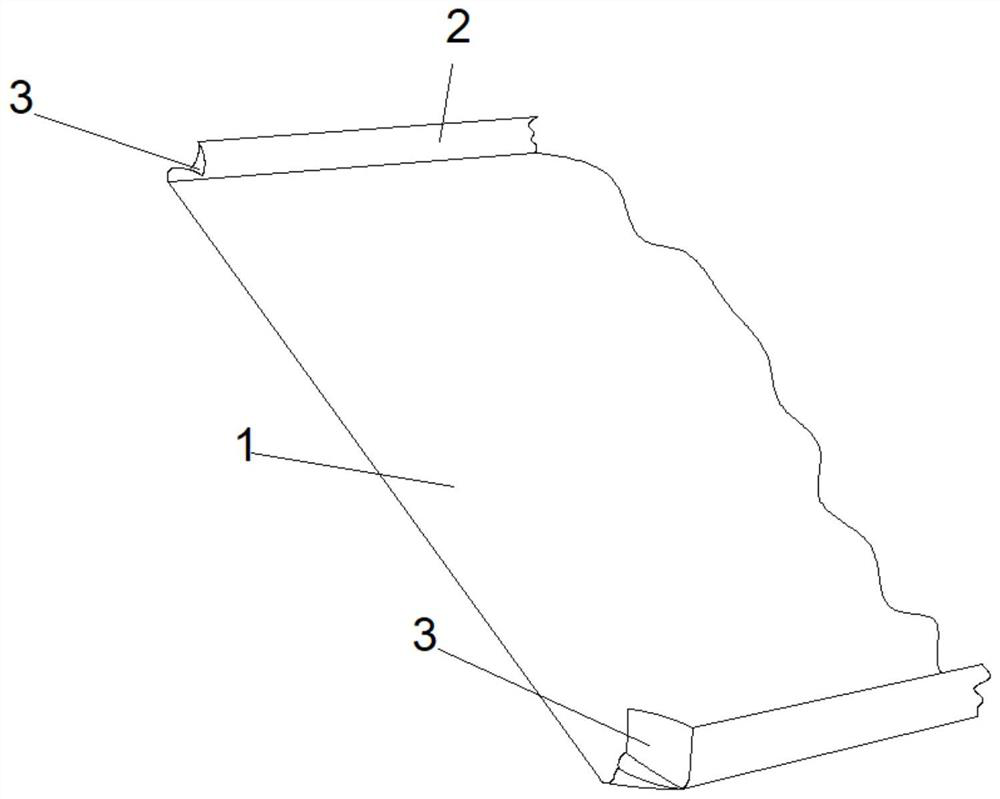

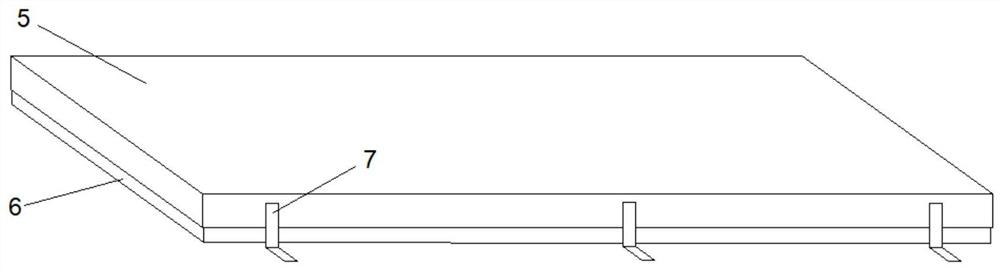

[0030] See figure 1 , the metal shell 5 of the box-shaped metal decorative insulation board is processed by a metal plate, and the metal plate can be a color-coated steel plate, a color-coated aluminum plate, a hot-dip galvanized steel plate, an galvanized steel plate or an aluminum-magnesium-manganese alloy plate, etc., according to Material selection is actually required.

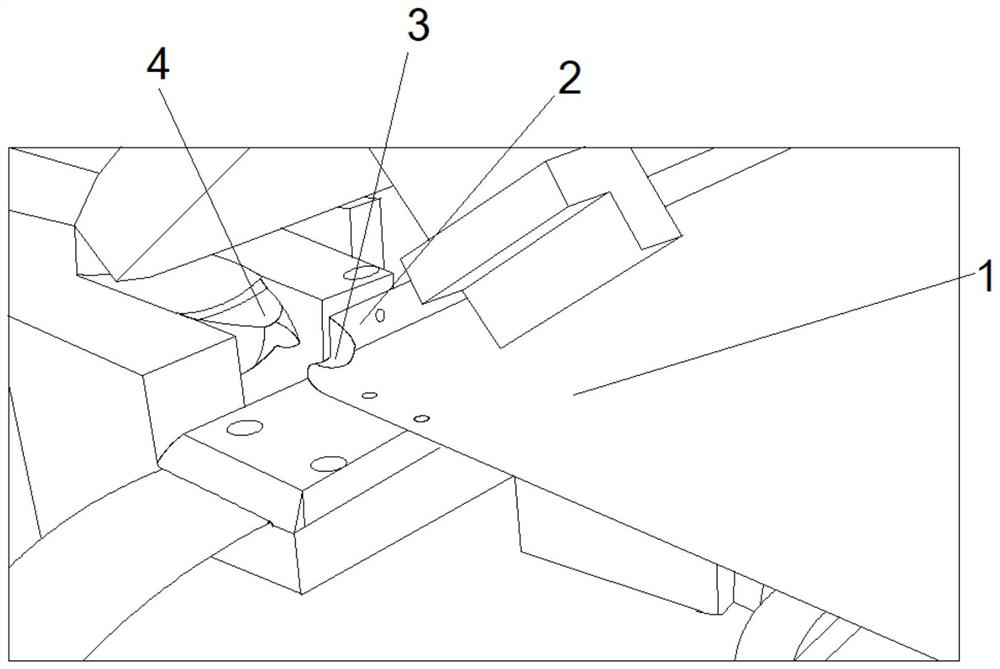

[0031] Equipment suitable for the non-breakage cornering method requires conveyor belts or conveying rollers, etc. for transporting the sheet metal, structures for bending the sides of the sheet metal, structures for fixing the sides of the sheet metal, and structures for pushing inwards Corner jacking tool. see figure 1 and Figure 7 , preferably the lower part of the front end of the pushing tool adopts a bottom surface inclined forward and upward, and the middle part of the lower surface is an arc-shaped groove. More preferably, the head 4 of the pushing tool is in the shape of a cross cone with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com