Cementing technology for 5.5-cun sleeve windowed side drilled slim hole

A sidetracking and cementing technology of window opening, which is applied in wellbore/well components, flushing wellbore, earthwork drilling and production, etc. It can solve the problems of high risk of leakage prevention operation, long period, and high risk of large-sized casing. To achieve the effect of improving the cementing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below with reference to the examples, but the embodiments of the present invention are not limited thereto.

[0024] The example is Well Side 1-11:

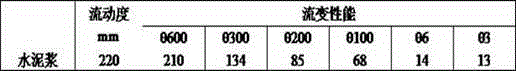

[0025] 1. Well structure data table

[0026]

[0027] 2. Using cement slurry system formula

[0028] Specific gravity of cement slurry: 1.40g / cm 3 , parts by weight: 100 parts of G grade oil well cement (Jiangnan G grade), 18 parts of floating beads, 12 parts of reinforcing agent (ultrafine cement), 3 parts of fluid loss reducing agent (G304), 0.5 parts of drag reducing agent (USZ) , 0.2 parts of retarder (GH-6), 85 parts of water and 2 parts of inorganic fiber (fiber length 6mm);

[0029] 3. Calculation of the critical displacement of plug flow in the well

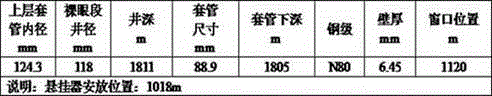

[0030] 1. Table of rheological properties of cement slurry

[0031]

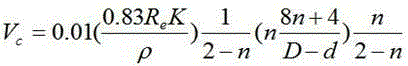

[0032] 2. Determine the rheological pattern

[0033] B=(φ200-φ100) / (φ300-φ100)=0.26≠0.5±0.03

[0034] Power-law rheol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com