One-piece terminal application-based hardness detection method

A technology of terminal application and detection method, applied in the direction of testing material hardness, etc., can solve the problems of inconvenient portability, large size of testing equipment, limited testing requirements, etc., to achieve the effect of improving efficiency, shortening measurement time, and shortening measurement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the device for realizing data variation and conversion is integrated in the data processor, which is a conventionally known device, and the parameter ratio in the standard database is an industry standard, which will not be specifically described in this embodiment.

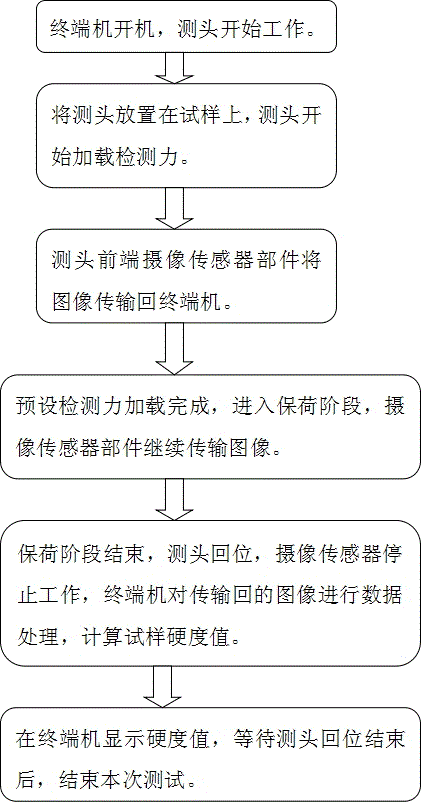

[0029] Such as figure 1 As shown, the hardness detection method based on the integrated terminal application disclosed in this embodiment includes the following steps:

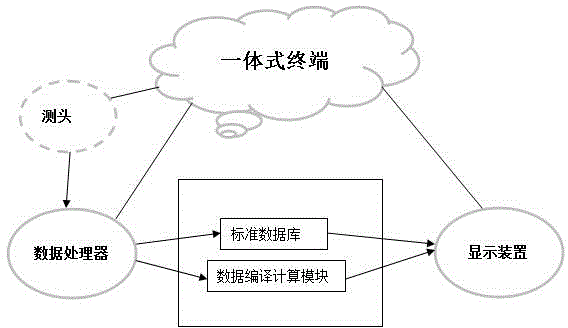

[0030] (1) Set up an integrated terminal, including a measuring head, a camera, a camera sensing component and a data processor; the measuring head, camera, camera sensing component and data processor are integrated and realized, and the camera sensing The above-mentioned camera is directly connected, and the sensor part of the camera is directly arranged at the front end of the measuring head.

[0031] (2) The terminal is turned on, the probe is placed on the sample, and the detection force is started; the probe is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com