Laser processing system and laser processing method thereof

A laser processing and laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low processing efficiency, limited processing efficiency, low stability, etc., and achieve improved processing efficiency, improved processing efficiency, Adjust quick and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

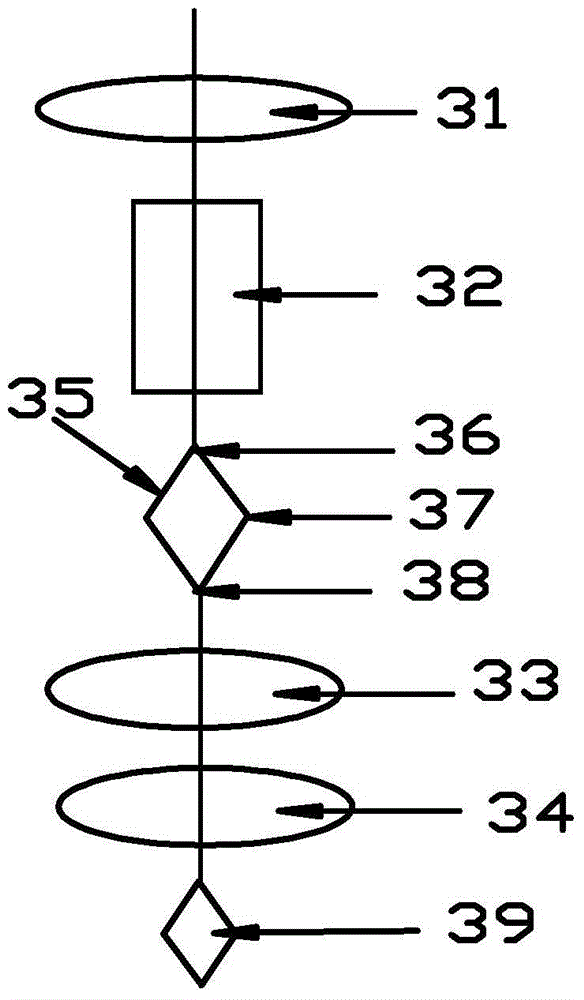

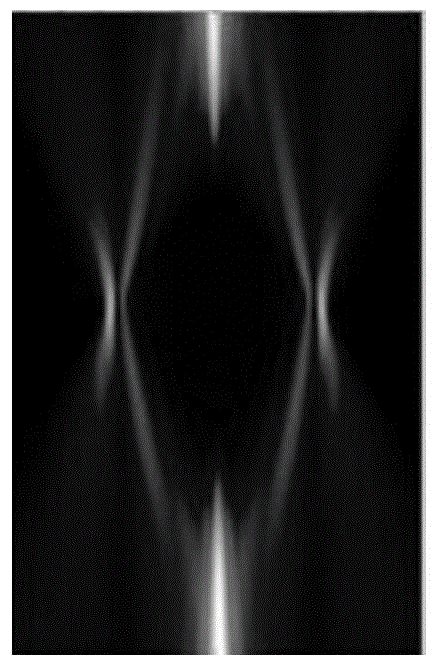

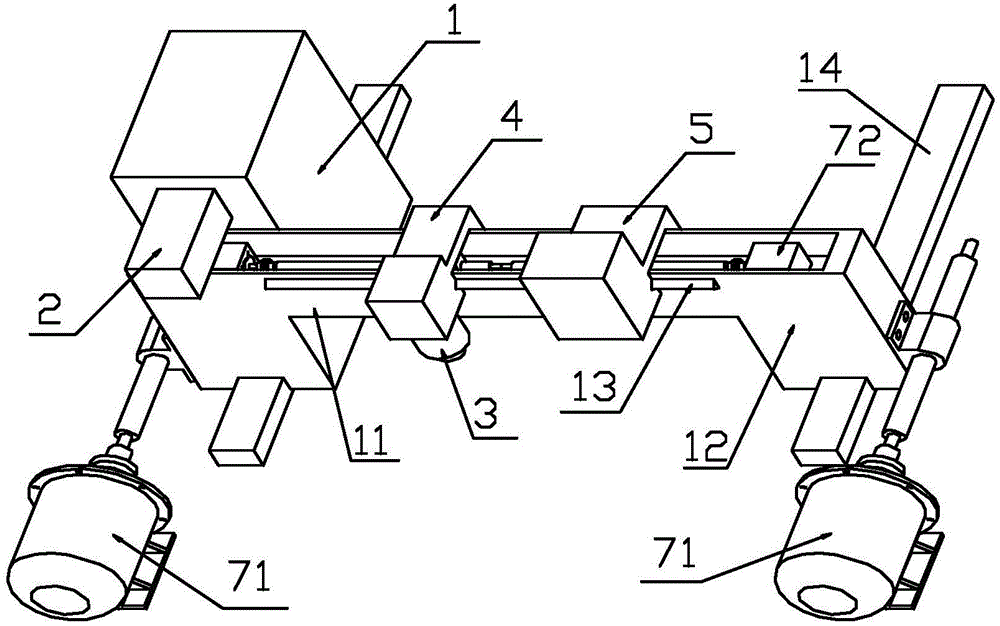

[0037] like figure 1 and figure 2 As shown, a laser processing system includes a frame 1, a laser 2, a laser head 3, a first fixed frame 4, a second fixed frame 5, a mirror 61, a mirror 62, a mirror 63, two servo motors 71 and 2 servo motors 72; the frame 1 is in the shape of a "door" and includes a beam 11 and 2 support beams 12, and the laser 2 is fixedly connected to the frame 1. The crossbeam 11 is provided with the first guide rail 13 in the horizontal direction, and the first fixed frame 4 and the second fixed frame 5 are both in the shape of "I", and the first fixed frame 4 and the second fixed frame 5 all span the On the crossbeam 11, first sliders are provided on the inner side of the first fixed frame 4 and the inner side of the second fixed frame 5, and the first sliders are matched with the first guide rail 13, and the crossbeam 11 is a groove structure, The servo motor 72 is located in the groove of the crossbeam 11, and the shafts of the servo motor 72 are fix...

Embodiment 2

[0066] The same part as embodiment 1 will not be repeated, and the difference is:

[0067] The present invention also provides a method for laser processing using the above-mentioned laser processing system, comprising the following steps:

[0068] (1) if figure 2 As shown, according to the needs of processing, adjust the position of the first fixed frame 4 and the second fixed frame 5, determine the optical path length z, after setting, in the process of processing, the first fixed frame 4 drives the laser head 3 along the second guide rail 14 While moving, the second fixed frame 5 moves in the same direction as the laser head 3, and moves at 1 / 2 speed of the laser head 3 to ensure that the constant optical path length z is maintained during the movement of the laser head 3;

[0069] (2) After the laser light output by the laser device 2 is reflected by the mirror 6 in turn, the laser light is introduced into the laser head 3 to obtain the incident light beam 8;

[0070] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com