A workshop processing trolley

A technology of trolleys and workshops, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of inconvenient cutting and recycling, inconvenient use, waste of resources, etc., and achieve the effect of easy movement, easy use, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

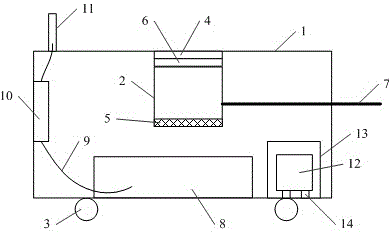

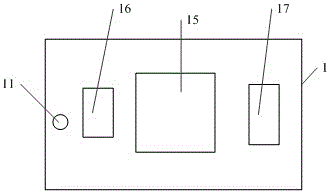

[0023] In the first embodiment, a workshop processing trolley is provided, please refer to Figure 1-Figure 2 , the trolley includes:

[0024] Shell 1, cylinder 2, the bottom surface of the shell is provided with brake casters 3, the inside of the shell is a hollow structure, the upper surface of the shell is provided with a first opening 15, and the lower surface of the first opening is inlaid with a first magnet Ring 4, the first opening is located in the first magnet ring, the upper and lower ends of the cylinder are open, the lower end of the cylinder is provided with a filter 5, the upper end of the cylinder is connected to the second magnet ring 6, The second magnet ring is adsorbed on the first magnet ring, one end of the operating rod 7 is connected to the side of the cylinder, and the other end of the operating rod extends through the side of the housing to the outside of the housing, and the cylinder A pool 8 is provided below the tube, and one end of the water pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com