Loader electronic-control-handle steering and intelligent-braking control system

A technology of braking system and braking control, which is applied in the direction of electric steering mechanism, fluid steering mechanism, automatic starting device, etc. It can solve the problems of vehicle overturning and braking not in time, achieve small energy loss, prevent accidents, and enhance safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

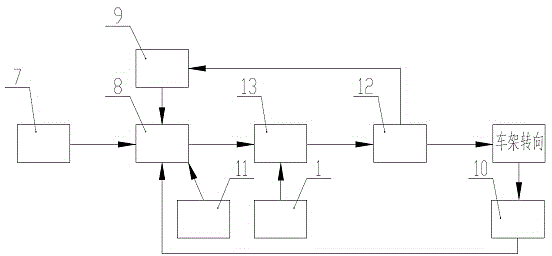

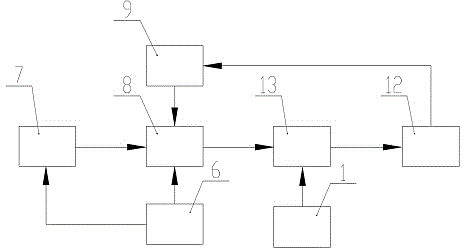

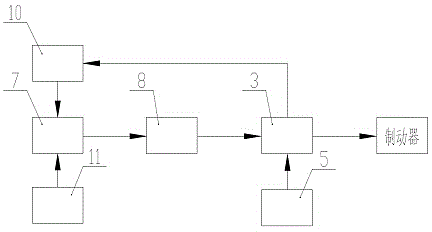

[0031] exist figure 1 Among them, the electric control handle steering and intelligent braking control system of the loader includes a steering pump 1 and a hydraulic oil tank 2, the oil inlet of the working pump 1 is connected to the hydraulic oil tank 2, and the oil outlet of the working pump 1 is connected to the electro-hydraulic proportional flow amplifying valve 13 The oil inlet P is connected, the electro-hydraulic proportional flow amplifying valve 13 is respectively connected with the steering cylinder 12, the PF port of the electro-hydraulic proportional flow amplifying valve 13 is connected with the unloading valve 16, and the EF port of the unloading valve 16 is connected with the working system. The a port of the charge valve 16 is connected with the b1 port of the distribution valve, the R1 and L1 ports of the electro-hydraulic proportional flow amplification valve 13 are connected with the ECU control box 8, and the pressure sensor 9 is installed in the large c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com