Water vertical assembly technology of prestressed concrete water fixed platform

A fixed platform and concrete technology, applied in water conservancy projects, underwater structures, buildings, etc., can solve the problems of self-heavy, bulky, and difficult to effectively reduce transportation costs of fixed platforms, so as to reduce construction costs and improve safety. , the effect of reducing transportation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

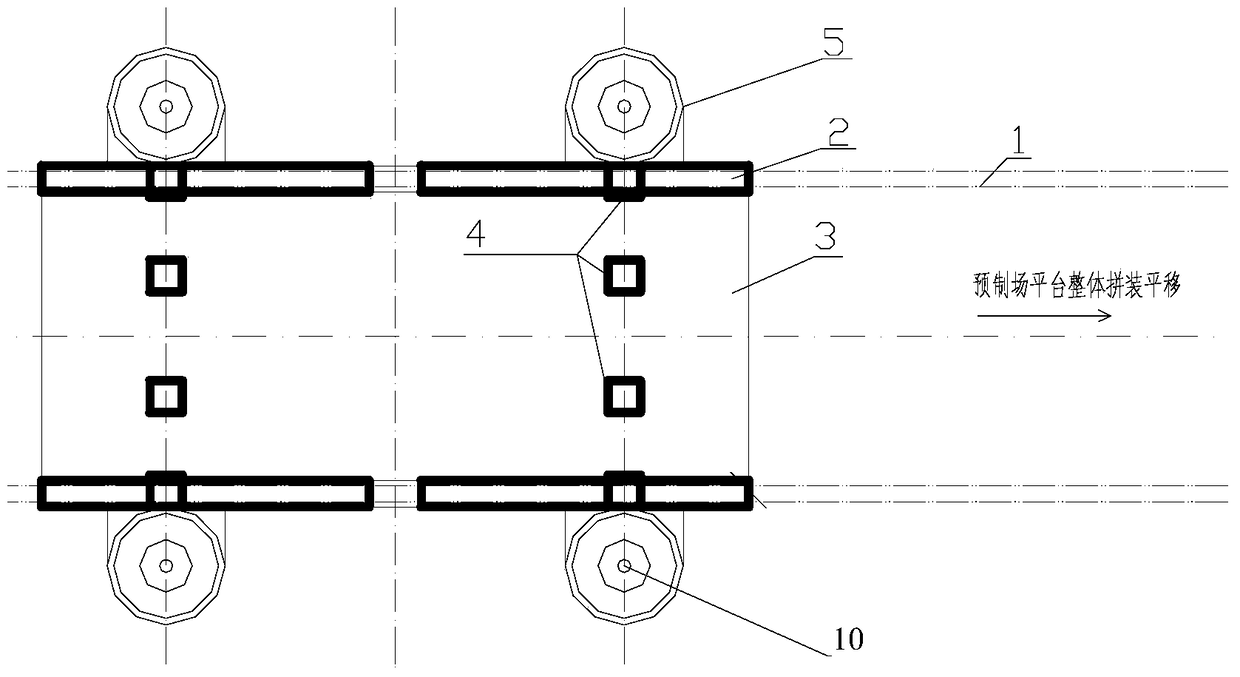

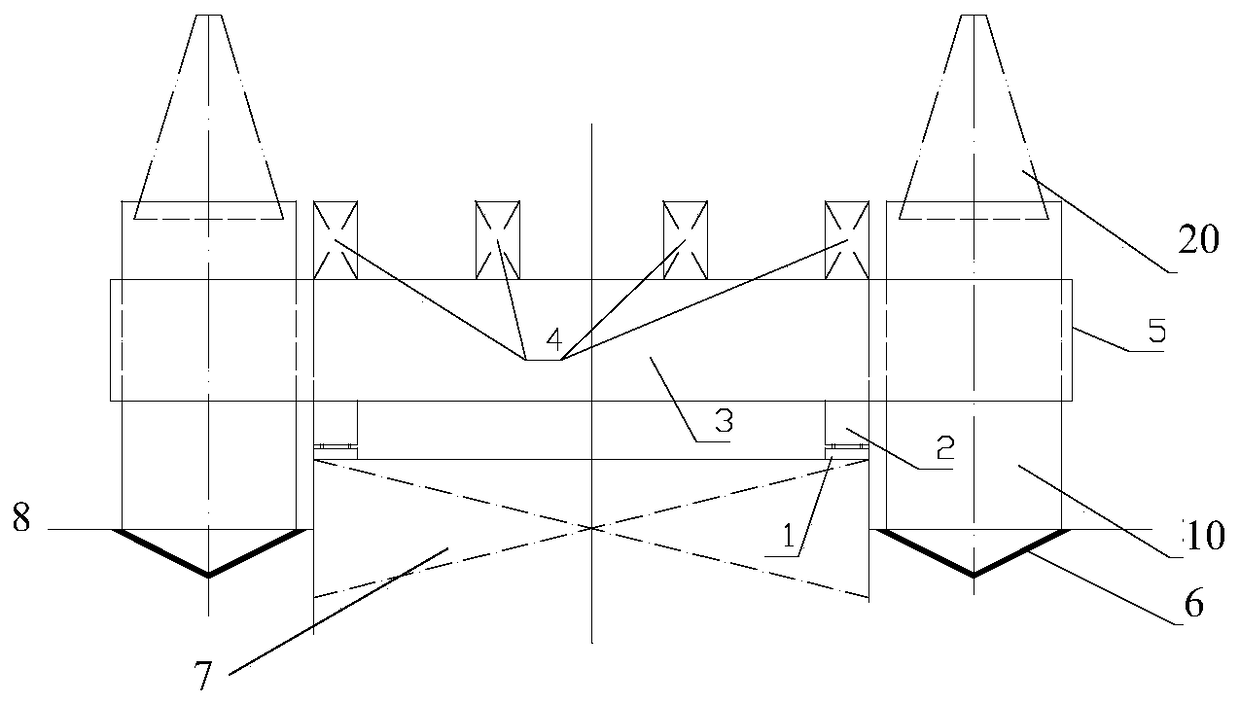

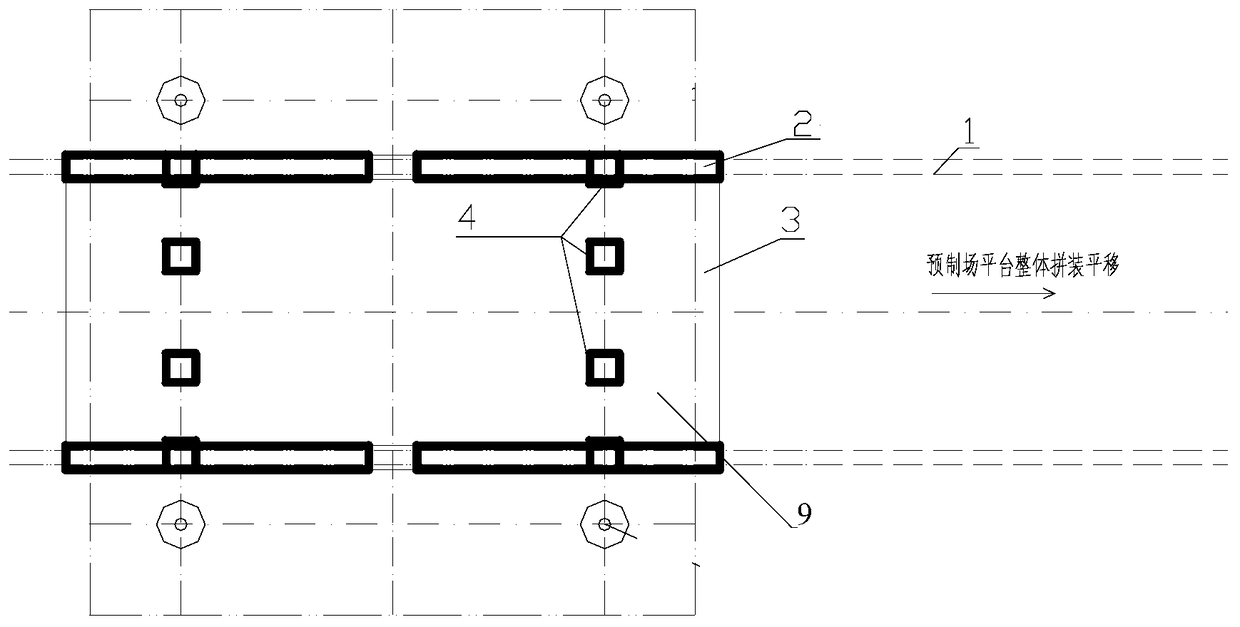

[0030] In the various figures of the application, structurally identical or functionally similar features are indicated by the same reference numerals.

[0031] This description will schematically but not limitatively illustrate the offshore vertical assembly technology according to the prestressed concrete fixed ocean platform. It should be clear that this fixed ocean platform can also be any large-scale water structure facility, that is to say the vertical The assembly technology can be applied to the construction of any prestressed concrete water fixed platform.

[0032] In addition, this description does not involve the reinforced concrete manufacturing process of each module of the prestressed concrete water or offshore fixed platform. Those skilled in the art can use any known reinforced concrete construction method to construct this prefabricated concrete structure in the prefabricated site of the land factory. Individual components of stressed concrete aquatic or marin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com