Novel aluminum alloy-concrete combined beam

A concrete and aluminum alloy technology, applied in joists, girders, trusses, etc., can solve problems such as insufficient shear connection, achieve good economy and applicability, reduce production costs, and reduce deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

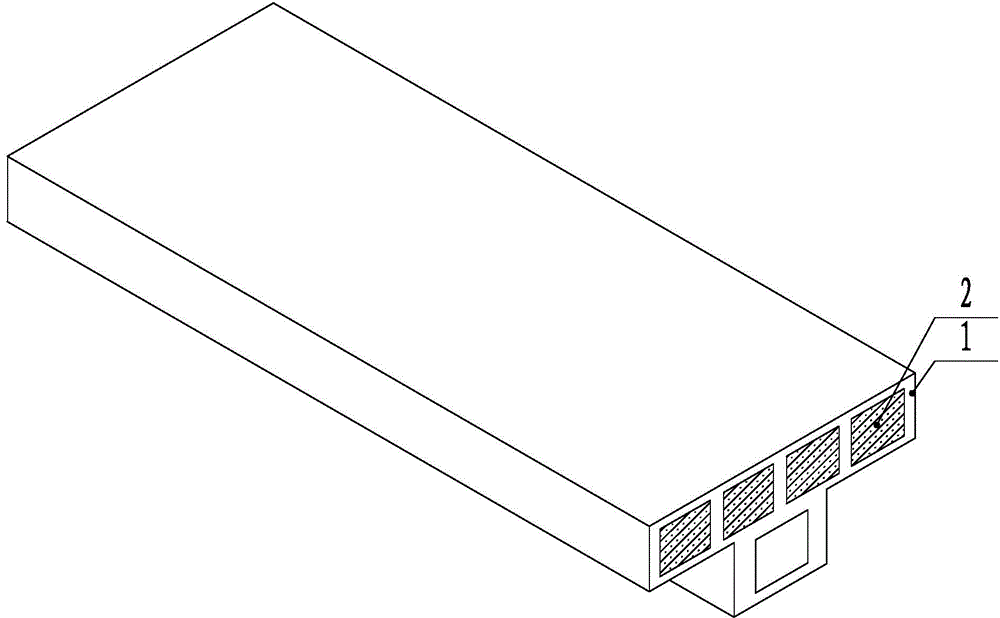

[0018] Embodiment one: if figure 1 As shown, the technical solution includes an aluminum alloy profile 1 with a cavity. The aluminum alloy profile 1 is in a "T" shape and is divided into an upper part and a lower part. The upper part is wider than the lower part. The upper part of the aluminum alloy profile 1 is provided with A plurality of cavities, the cavities on the upper part of the aluminum alloy profile 1 are filled with concrete 2 . An aluminum alloy profile 1 with multiple cavities is integrally extruded.

[0019] In order to take both strength and production cost into account, the upper part of the aluminum alloy profile 1 is provided with four parallel cavities, the lower part of the aluminum alloy profile 1 is provided with one cavity, and the cavity in the lower part of the aluminum alloy profile 1 is not filled with concrete 2 ; Aluminum alloy profiles 1 with multiple cavities are integrally extruded. Among them, the cross-sectional area of the cavity account...

Embodiment 2

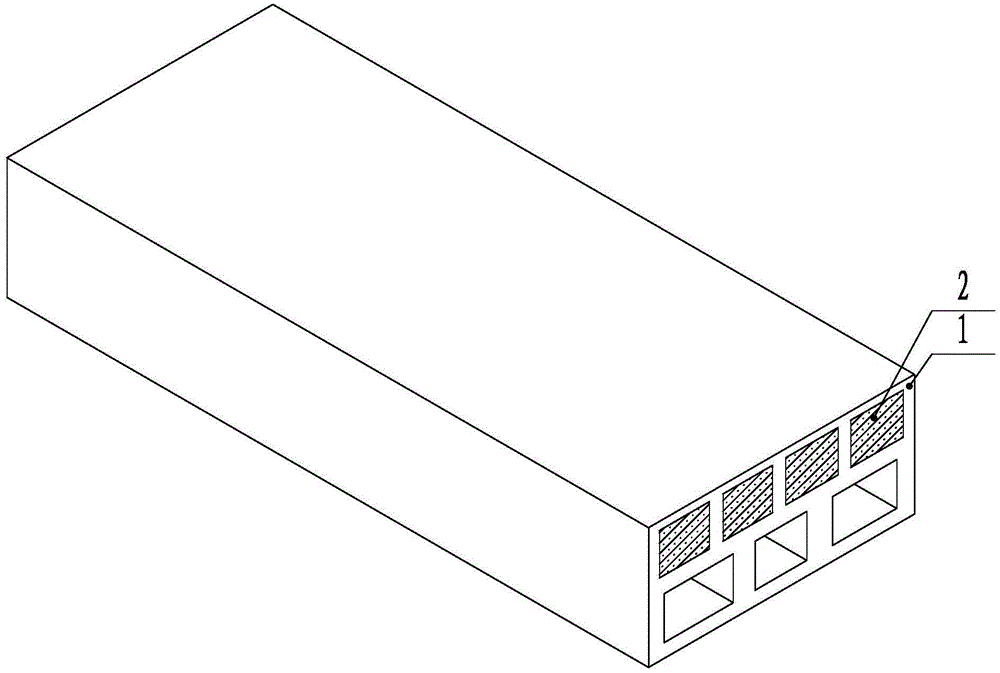

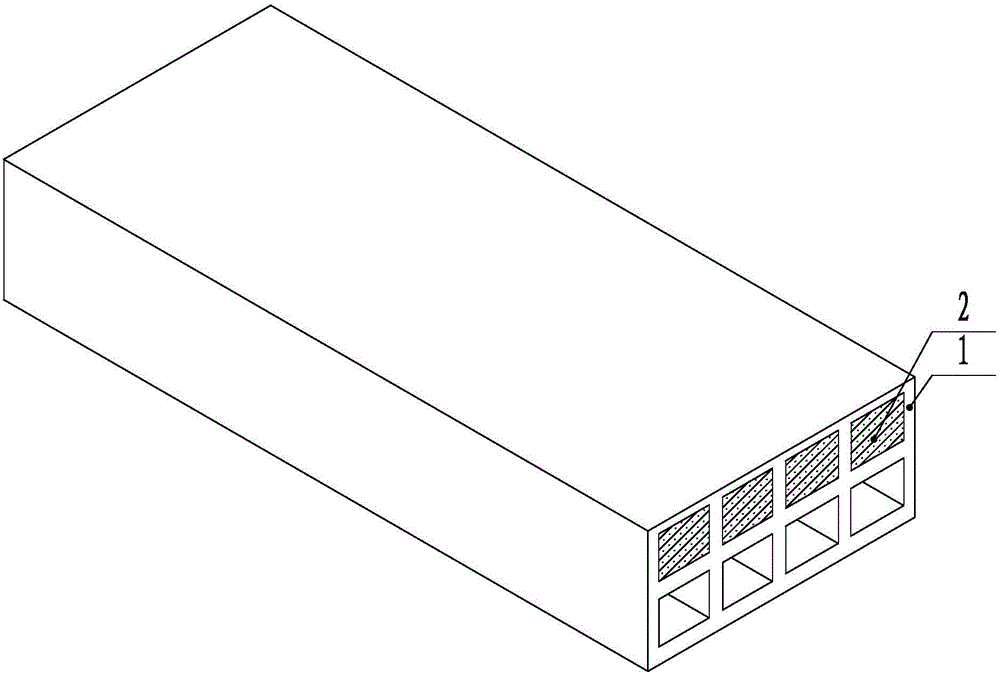

[0023] The difference from Embodiment 1 is that the aluminum alloy profile 1 is in the shape of a "day", the upper part and the lower part of the aluminum alloy profile 1 are equal in width, and one or more cavities are provided in the lower part of the aluminum alloy profile 1, and the upper cavity of the aluminum alloy profile 1 and the The cavity in the lower part of the aluminum alloy profile 1 is staggered, such as figure 2 shown, or juxtaposed, such as image 3 shown. The "day" shape of the aluminum alloy profile 1 can further improve the strength of the composite beam and increase the bearing capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com