Novel adjusting air cylinder

A new type of technology for adjusting the cylinder, which is applied in the direction of fluid pressure actuators, engine components, cylindrical pistons, etc., can solve problems such as unsatisfactory effects and limited cylinder strokes, achieve good sealing, increase lifting frequency, reduce small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Specific embodiments of the present invention will be further described in detail below.

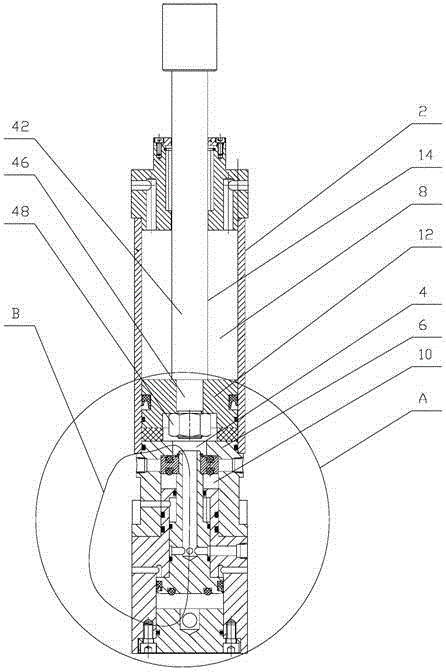

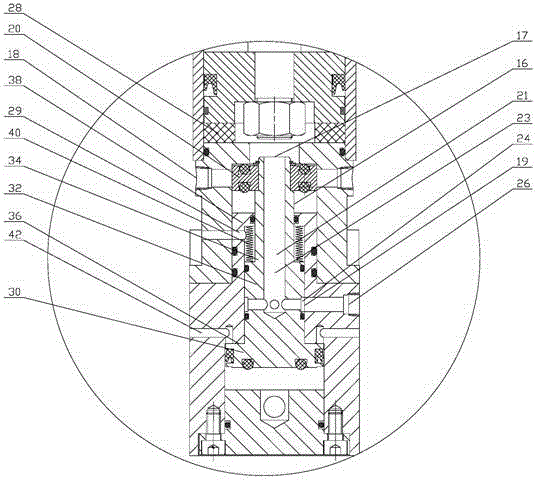

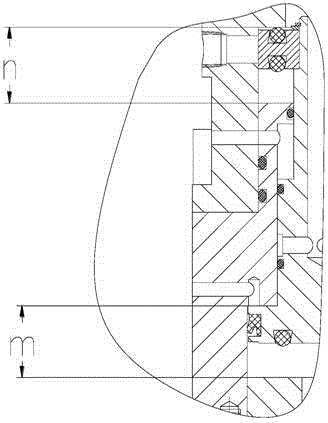

[0035] like Figure 1-3 As shown, the present invention includes a hollow cylinder 2, a first boss 6 with a central hole 4 is arranged on the inner wall of the cylinder, and the first boss 6 divides the inner cavity of the cylinder into a first cavity chamber 8 and the second chamber 10, and communicated through the central hole 4, the first chamber 8 is provided with a piston 12 slidingly fitted therein and a piston rod 14 fixed on the piston 12, the The second chamber 10 includes:

[0036] - the valve core 16, which is slidingly fitted with the outer wall of the second chamber 10, the valve core 16 is connected with a power device that drives it to move linearly along the axial direction of the second chamber 10, the valve The core 16 also includes a first end portion arranged at the proximal end of the first boss 6, the first end portion is provided with a first air outlet ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com