Digestion device for protein measurement

A digestion apparatus and protein technology, applied in the field of digestion apparatus, can solve the problems of slow temperature rise, large power consumption, internal pressure of digestion tank, etc., and achieve the effect of fast temperature rise and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

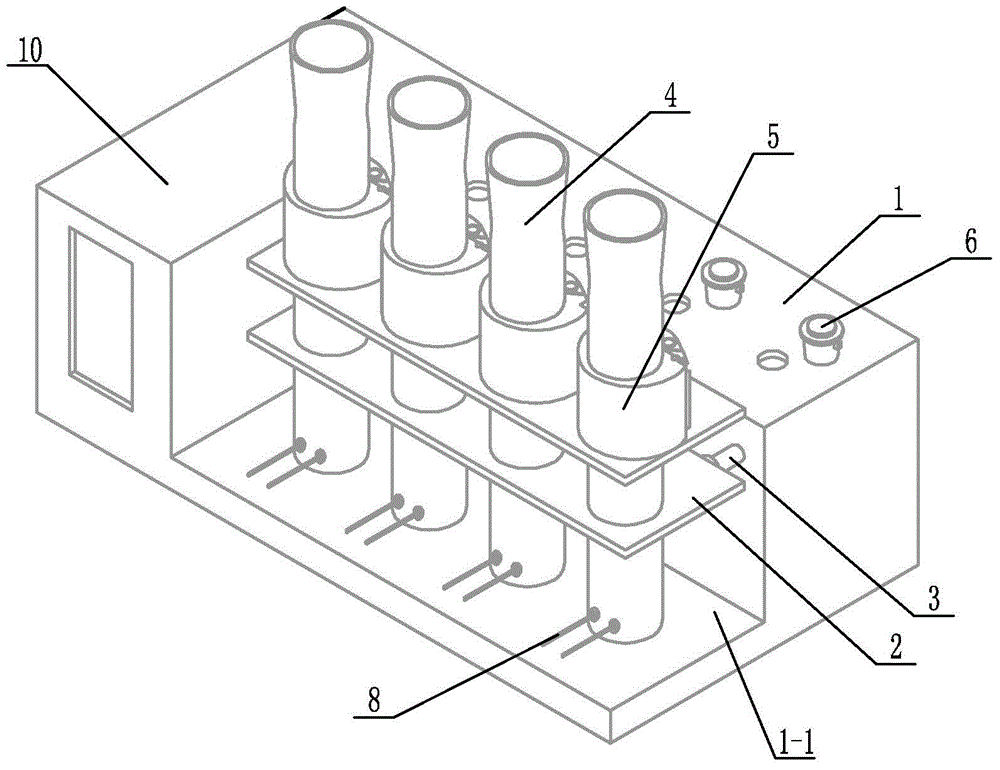

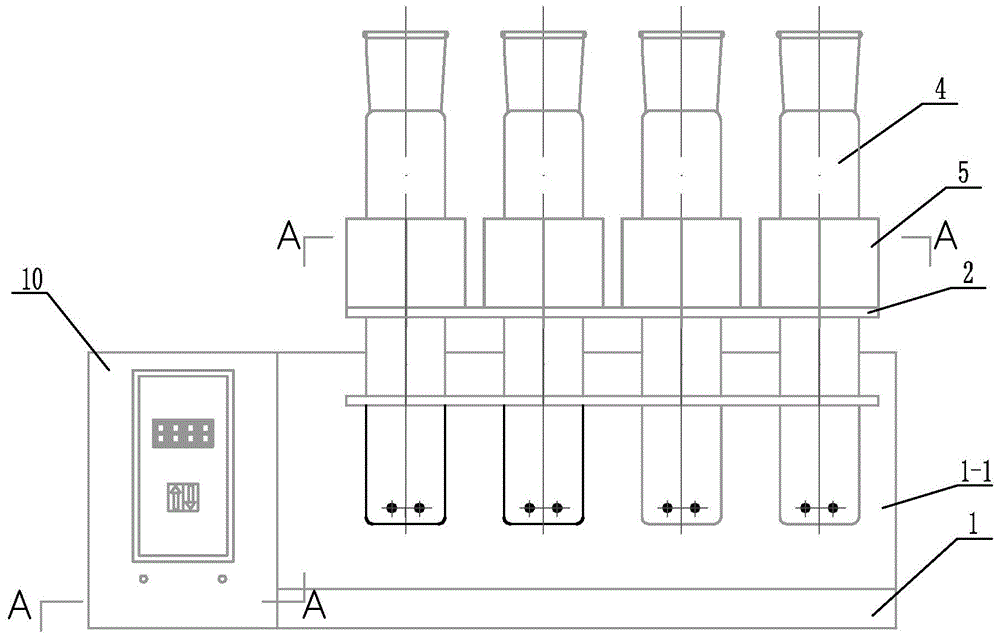

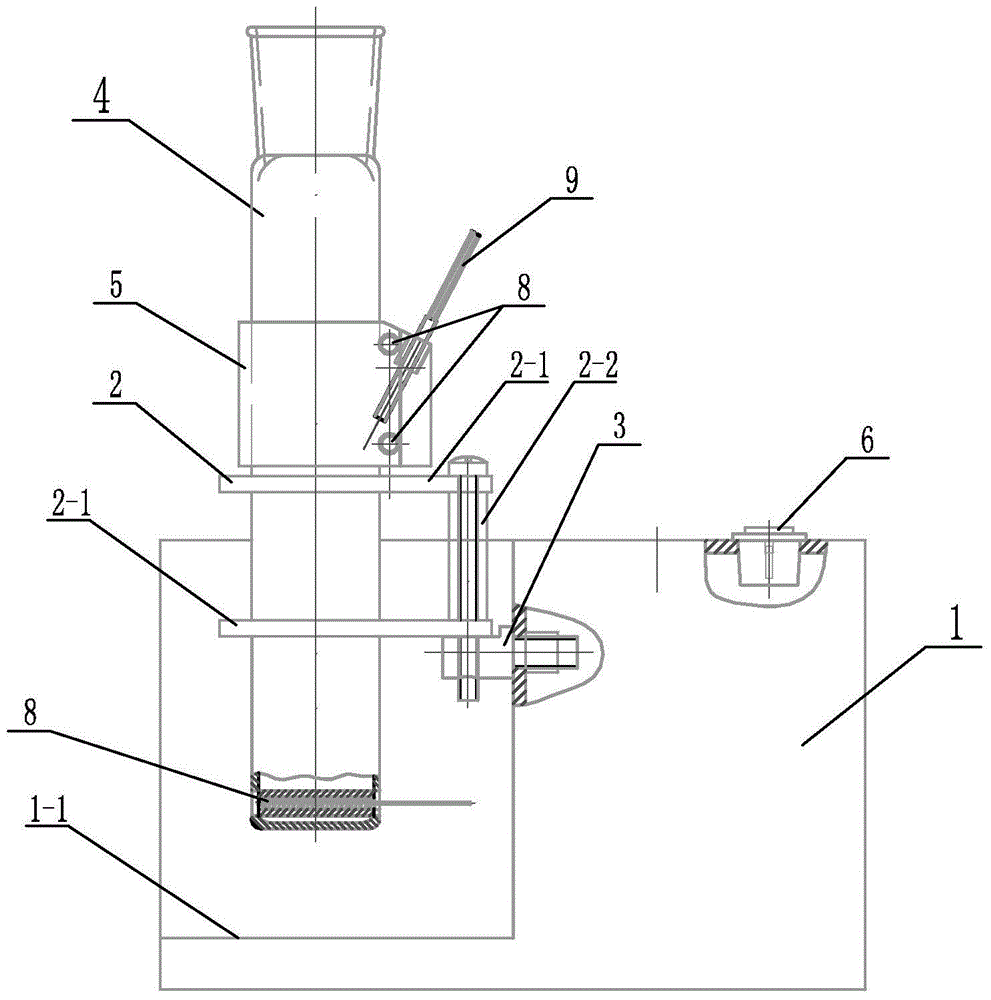

[0020] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment. This embodiment includes a chassis 1, a mounting seat 2, several horizontal base columns 3, several internal heat digestion tubes 4, several temperature control seats 5, several switches 6, several through pipes 7, several A U-shaped heating wire 8 and several temperature sensors 9,

[0021] The front end of the cabinet 1 is provided with a right-angled groove 1-1 for placing the internally heated internal heat digestion tube 4, one side of the cabinet 1 and the end of the right-angled groove 1-1 is an electrical control box 10, several horizontal base columns 3 It is arranged in parallel in the right-angle groove 1-1 and connected with the chassis 1 through connecting elements. The installation base 2 is arranged on the horizontal base column 3 and connected with the horizontal base column 3 through connecting elements. Several internal heat digestion pipes 4 are vertically and pa...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination Figure 9 ~ Figure 12 To illustrate this embodiment, the center of the temperature control seat 5 of this embodiment is provided with a digestive tube installation hole 5-1 along the vertical direction, and the side wall of the temperature control seat 5 is provided with an inclined hole 5-2 and two straight holes. Hole 5-3, inclined hole 5-1 is inclined from top to bottom and from outside to inside, two straight holes 5-3 are arranged in parallel up and down, and the centerline of straight hole 5-3 and the centerline of digestive tube installation hole 5-1 perpendicular to each other. The digestion tube installation hole 5-1 is used for installing the internal heat digestion tube 4, the oblique hole 5-2 is used for installing the temperature sensor 9, and the straight hole 5-3 is used for installing the U-shaped heating wire 8. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination Figure 13 Describe this embodiment, one end of the horizontal base column 3 of this embodiment is a cylinder, the other end is a bolt 3-1, the upper end surface of the cylinder is provided with a horizontal plane 3-2, and the cylinder is provided with a horizontal plane 3-2. Vertical connecting holes 3-3. The bolt 3-1 is used to connect with the nut so that the horizontal base column 3 is fixed on the chassis 1, the horizontal plane 3-2 is used to support the mounting base 2, and the connection hole 3-3 is used to install connecting elements so as to fix the mounting base 2 On the horizontal base column 3. The other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com