Positioning method for pattern-free silicon chip measurement

A positioning method and a pattern-free technology, which is applied in the direction of measuring devices, semiconductor/solid-state device testing/measurement, and optical devices, etc., can solve the problems of excessive beam measurement position deviation and measurement repeatability cannot be guaranteed, so as to improve the measurement Effect of repeatability, good measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the following detailed description of the preferred embodiment, reference is made to the accompanying drawings which form a part hereof. The accompanying drawings show, by way of example, specific embodiments in which the invention can be practiced. The illustrated embodiments are not intended to be exhaustive of all embodiments in accordance with the invention. It is to be understood that other embodiments may be utilized and structural or logical changes may be made without departing from the scope of the present invention. Accordingly, the following detailed description is not limiting, and the scope of the invention is defined by the appended claims.

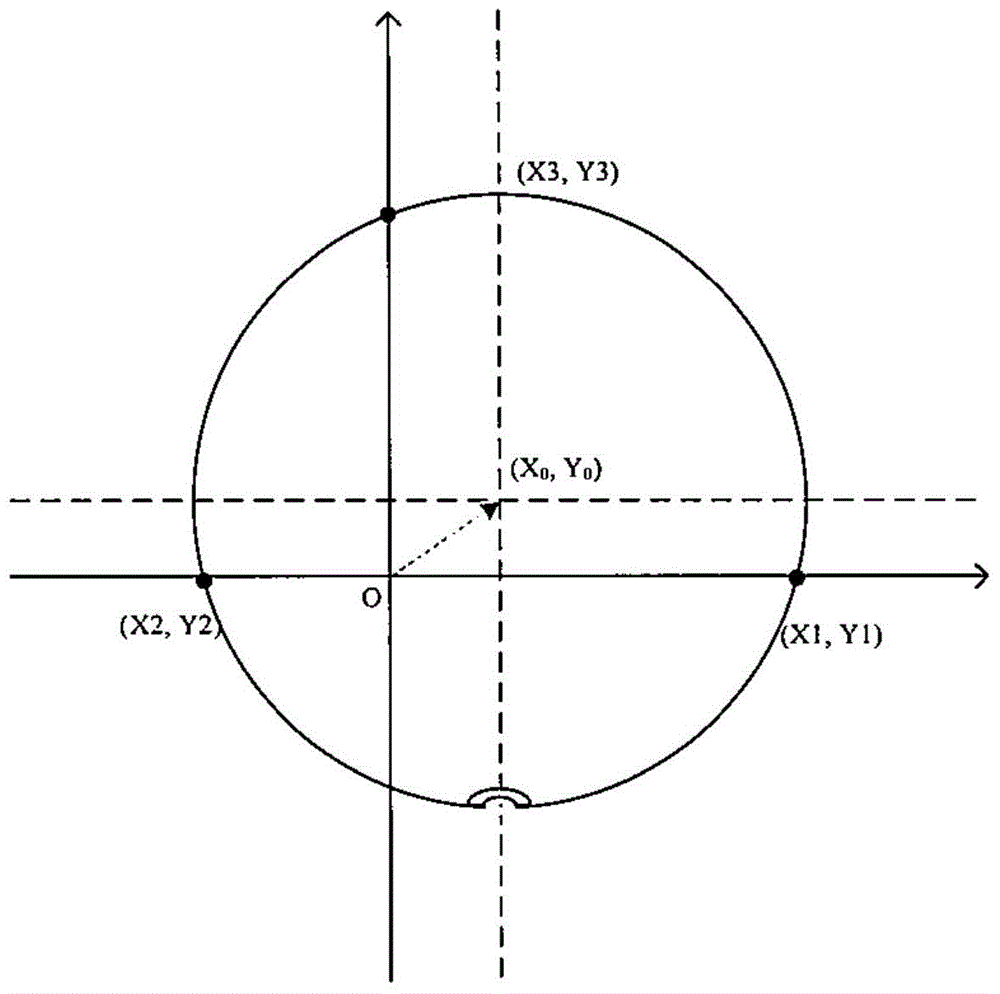

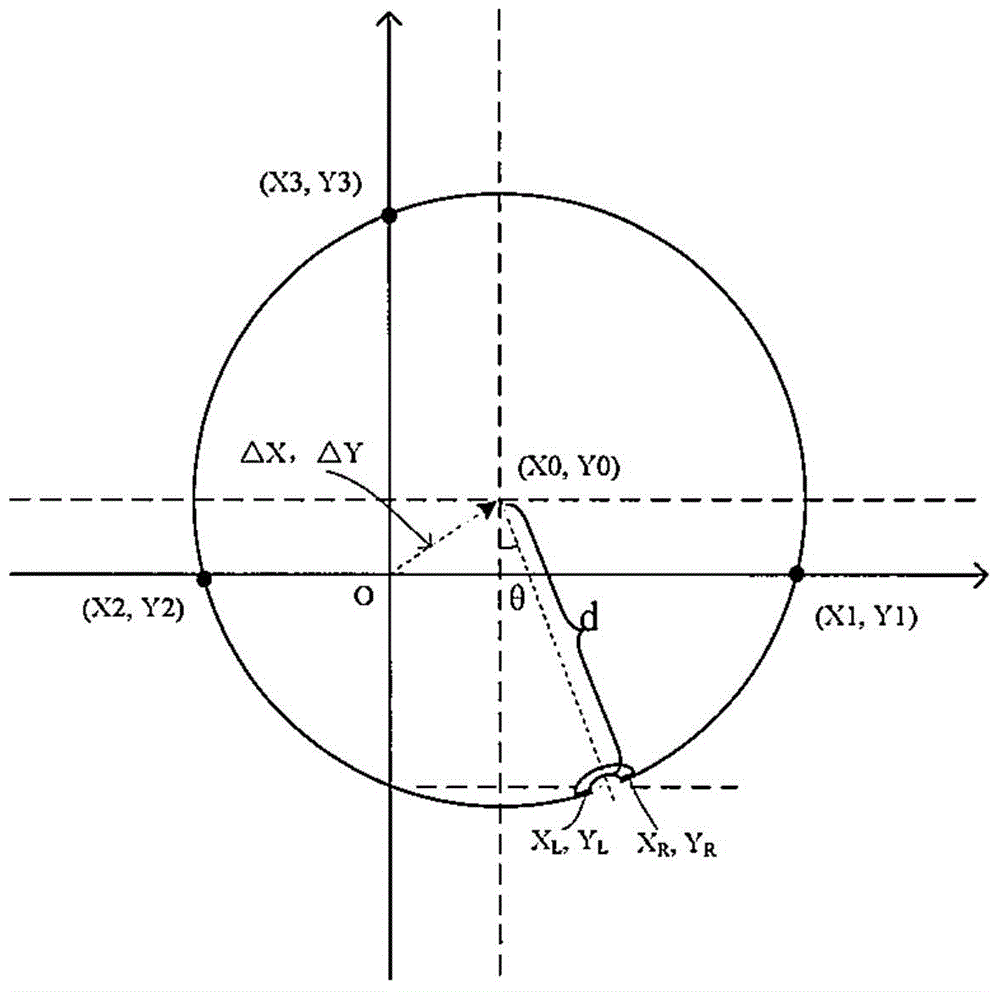

[0027] When measuring silicon wafers, the following two factors mainly cause the problem of low test repeatability during the loading process of silicon wafers:

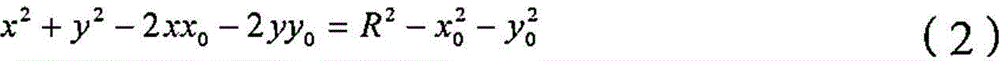

[0028] 1. The translation of the upper silicon wafer, that is, the coordinate value of the center of the upper silicon wafer in the system coordinate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com