Linear testing device for variable-density optical filter

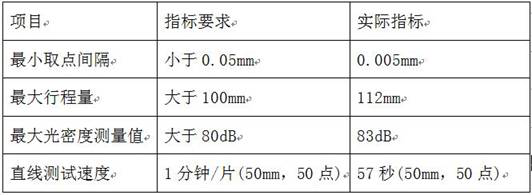

A testing device and filter technology, which is applied to measurement devices, optical instrument testing, and optical performance testing, etc., can solve the problems of low linear testing efficiency, no filter movement, low efficiency, etc., so as to facilitate subsequent processing. The effect of ideal processing and measurement accuracy and high test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

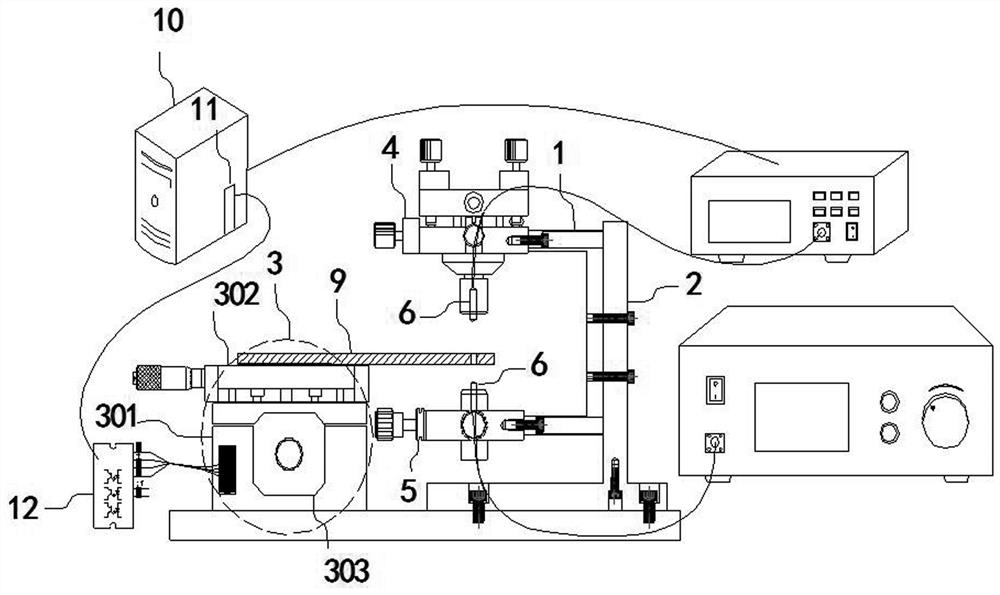

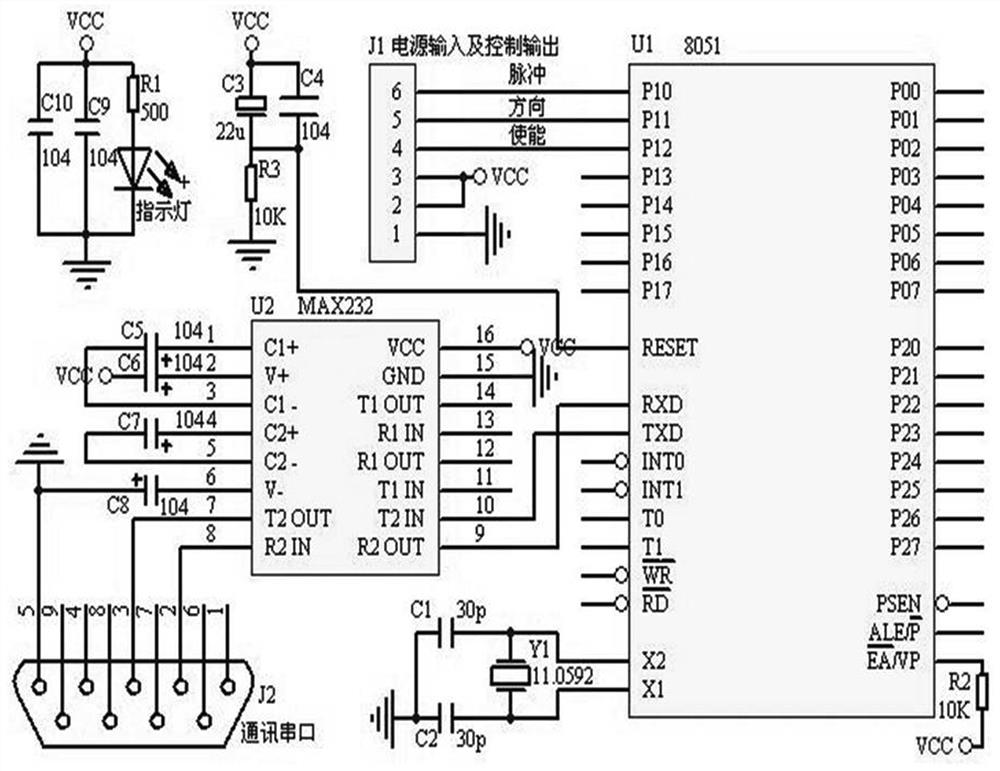

[0016] As shown in the figure, the variable density filter linear test device includes an inclination adjustment arm 1, an optical path support frame 2, a mobile platform 3, a four-axis optical fiber adjustment frame 4 and a two-axis optical fiber adjustment frame 5; the mobile platform 3 includes Y An axis translation unit 301 and an X-axis fine-tuning unit 302; the four-axis optical fiber adjustment frame 4 and the two-axis optical fiber adjustment frame 5 are respectively fixed at the upper and lower ends of the inclination adjustment arm 1; the optical fibers on the four-axis optical fiber adjustment frame 4 The optical fiber collimator 6 is respectively fixed at the optical fiber detection port of the light source and the two-axis optical fiber adjustment frame 5; The column of the arm 1 is fixedly connected with the optical path support frame 2; the Y-axis translation unit 301 includes a fine-tuning unit body, a computer 10, a single-chip microcomputer control board 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com