Measuring method ofgas hydrate specific surface area and adsorbance

A technology for gas hydrate and specific surface area, which is applied in measurement devices, material analysis using radiation diffraction, instruments, etc., can solve the problems of difficulty in measuring the quality of natural gas hydrate samples, and the inability to obtain further calculation of the measurement results, and achieves low cost. , the effect of good measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

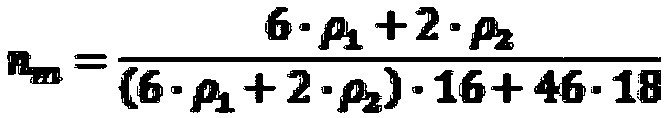

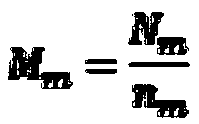

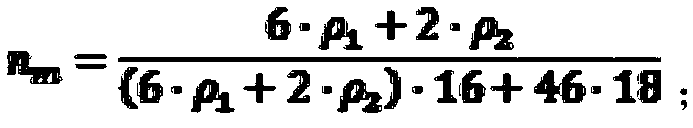

[0032] 1) Pre-cool the high-pressure physical adsorption instrument to a temperature range of -120 to -80°C, put an appropriate amount of methane hydrate sample into the high-pressure physical adsorption instrument and quickly vacuum, and then inject a certain amount of nitrogen in the high-pressure nitrogen bottle into the high-pressure In the physical adsorption instrument and measure the total amount of nitrogen injected into the high-pressure physical adsorption instrument N 1 ; After the adsorption process is completed, use the turbomolecular pump in the high-pressure physical adsorption instrument to extract unadsorbed nitrogen, and measure the total amount of this part of gas N 2, at the same time, this part of the gas is measured by a gas chromatograph due to the decomposition of part of the methane hydrate sample to produce methane component content y 1 ; Finally, the high-pressure physical adsorption instrument is heated up to completely decompose the methane hydrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com