A torque adaptive continuously variable permanent magnet inner rotor brushless motor

A brushless motor, self-adaptive technology, applied in the direction of magnetic circuit rotating parts, electrical components, electromechanical devices, etc., can solve problems such as difficult matching, and achieve the effect of less iron loss, high efficiency and less iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

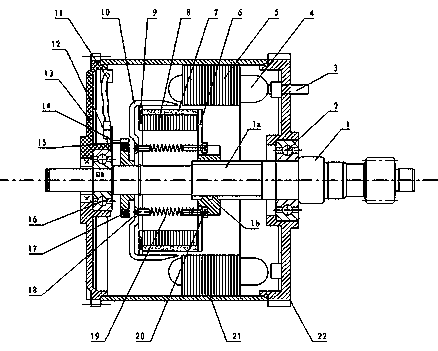

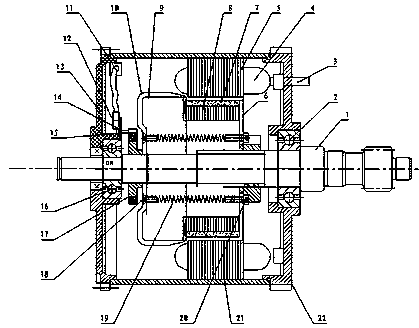

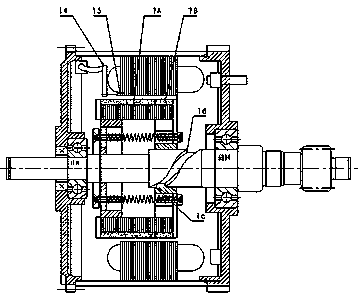

[0015] Combine below figure 1 and figure 2 Explain the adjustment principle and speed change process.

[0016] The following is an example of vehicle drive to illustrate the working process of the present invention's self-adaptive continuous variable speed: figure 1 In the state shown, under the action of the spring, the stator is biased to the left, and a part of the magnetic flux of the permanent magnet of the rotor enters the magnetic flux shunt to form a circuit without passing through the core coil. If the magnetic flux aligned with the magnet part of the stator core coil is called effective Flux linkage, then the flux linkage is the minimum value at this time, that is, the initial state is the flux-weakening state.

[0017] After electrification, if the applied electric power is small, such as when the vehicle is started on a flat road with a light load, take the handlebar operation as an example, and the motor will start from a low-voltage state with a weak magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com