dc‑dc converter with linear overtemperature protection circuit

An over-temperature protection circuit, DC-DC technology, applied in the direction of output power conversion devices, instruments, electrical components, etc., can solve the problems of abnormal operation of DC-DC converters, noise effects, etc., to avoid abnormal operation, The effect of smooth work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

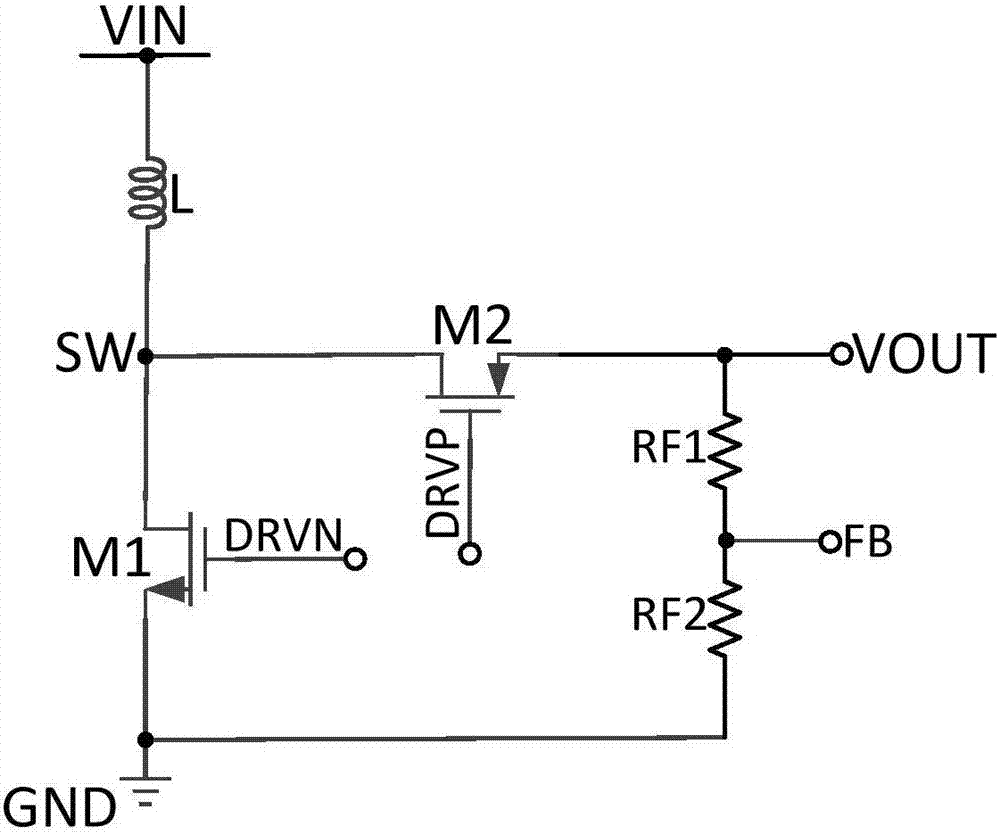

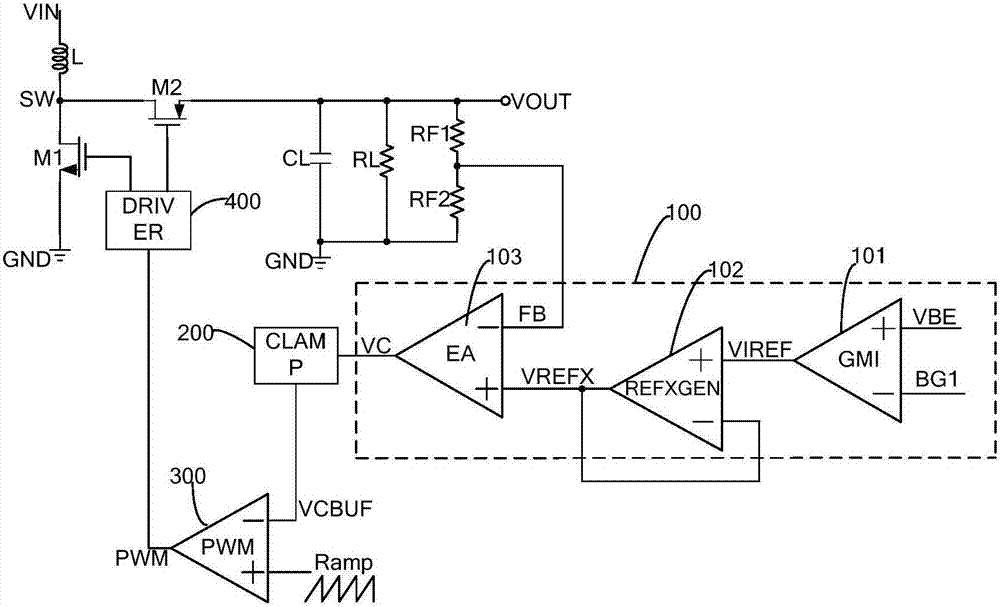

[0072] Such as image 3 As shown, the present invention provides a DC-DC converter with a linear over-temperature protection circuit including a DC-DC boost circuit part and a feedback circuit part, wherein the feedback circuit part includes: a linear over-temperature protection circuit 100, Clamping circuit 200, PWM signal generating circuit 300, driving circuit 400 and temperature transistor (not shown in the figure);

[0073] A temperature transistor, used to generate a junction voltage signal according to the collected temperature of the DC-DC converter;

[0074] A linear over-temperature protection circuit 100, configured to form an error amplification signal according to the junction voltage signal and the first reference voltage signal;

[0075] The clamping circuit 200 is used to limit the maximum value and the minimum value of the error amplification signal to keep the error amplification signal within a fixed voltage range, and form a temperature adjustment signal. ...

Embodiment 2

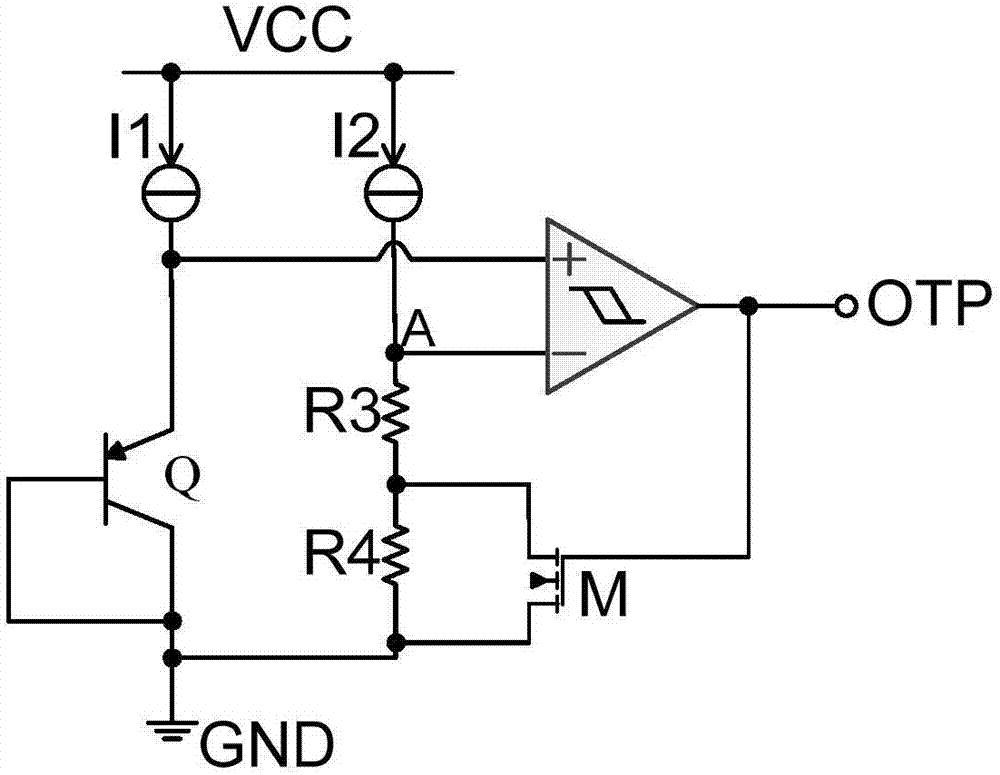

[0087] Such as Figure 3 ~ Figure 6 As shown, the embodiment of the present invention provides a linear over-temperature protection circuit. The linear protection circuit includes: a linear transconductance amplifier sub-circuit, a reference voltage generation sub-circuit and an error amplifier sub-circuit; wherein,

[0088] The non-inverting input end of the linear transconductance amplification sub-circuit is connected to the junction voltage signal, the inverting input end is connected to the first reference voltage signal, and the output signal end is connected to the non-inverting input end of the reference voltage generation sub-circuit, which is used for combining the junction voltage signal with the first reference voltage signal. A reference voltage signal forms a temperature deviation signal that maintains a linear relationship with temperature;

[0089] The inverting input end of the reference voltage generating subcircuit is connected to the output signal end, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com