Beneficiation method for separating weakly magnetic mineral and mica

A technology of weak magnetic ore and mineral processing method, applied in the field of mineral processing, can solve the problems of lack of mineral processing technology, large consumption of reagents, interference in flotation process, etc., and achieve high separation efficiency, improved utilization rate, and high process efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A low-grade ilmenite, TiO 2 The grade is 5.12wt%, and the particle size of ilmenite intercalation is 0.020-0.050mm; especially, the ore contains 3.89wt% flaky weak magnetic phlogopite, which cannot be removed by the commonly used pulsating high-gradient magnetic separation method; The treatment capacity of the method is too small to obtain economic benefits; the interference effect of the mica in the flotation process is very serious, the flotation reagent consumption is large, the production cost is high, and there is an environmental pollution problem, so it cannot be applied.

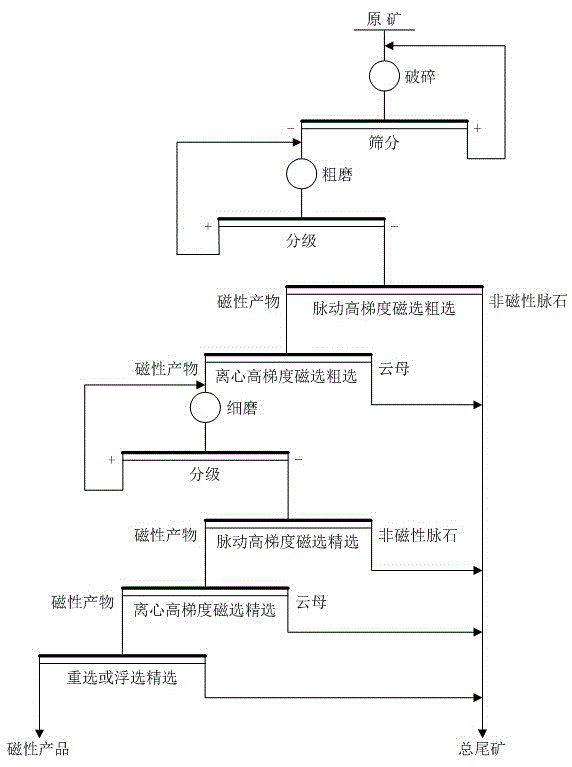

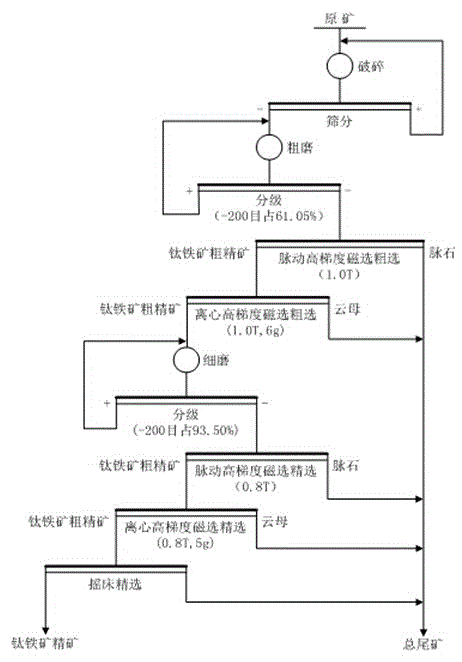

[0030] Such as figure 1 and 2 As shown, firstly, the weak magnetic ore is crushed, screened, coarsely ground, and classified to control the particle size -0.074mm to account for 61.05%, and then the classified weak magnetic ore is subjected to pulsating high-gradient magnetic separation to obtain discarded non-magnetic gangue and Contains magnetic products containing weakly magnetic metal or...

Embodiment 2

[0036] A low-grade limonite with an iron grade of 32.48wt%. The distribution of limonite is characterized by aggregates, and the particle size is unevenly distributed. The relationship with the gangue distribution is complicated. The commonly used pulsating high-gradient magnetic separation method cannot remove the phlogopite; the gravity separation method is too small to obtain economic benefits; the flotation process is not suitable for the beneficiation of limonite minerals.

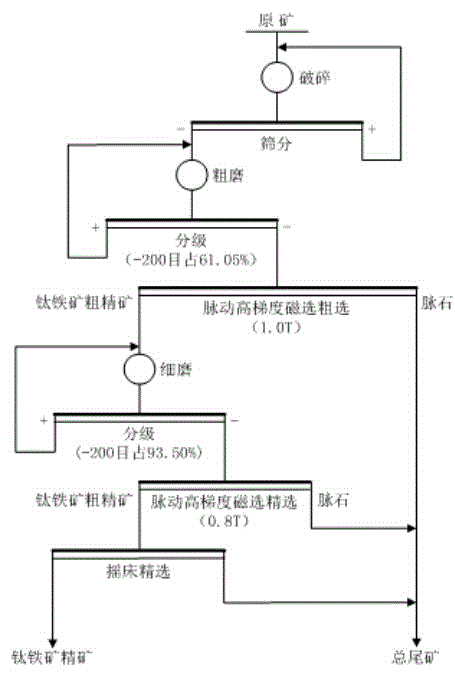

[0037] Such as figure 1 and 4 As shown, firstly, the weak magnetic ore is crushed, screened, coarsely ground, and classified to control the particle size -0.074mm, accounting for 62.05%, and then the classified weak magnetic ore is subjected to pulsating high-gradient magnetic separation to obtain discarded non-magnetic gangue and Contains magnetic products containing weakly magnetic metal ores and mica, and the obtained magnetic products containing weakly magnetic metal ores and mica are subjected t...

Embodiment 3

[0043] A certain hematite, with an iron grade of 29.07 wt %, belongs to fine-grained distribution, the iron minerals are mainly hematite, and the gangue minerals are quartz and chlorite, containing 3.01wt% flaky weak magnetic mica. Mica cannot be removed by high gradient magnetic separation. The high gradient magnetic separation method has the advantages of no environmental pollution and low production cost.

[0044] Such as figure 1 and 6 As shown, firstly, the weak magnetic ore is crushed, screened, coarsely ground, and classified to control the particle size -0.074mm to account for 60%, and then the classified weak magnetic ore is subjected to pulsating high-gradient magnetic separation to obtain discarded non-magnetic gangue and Contains magnetic products containing weakly magnetic metal ores and mica, and the obtained magnetic products containing weakly magnetic metal ores and mica are subjected to centrifugal high-gradient magnetic separation to obtain magnetic product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

| eccentricity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com