Rapid prototyping method for investment casting

A molding method and investment casting technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of high single-piece price, low manufacturing cost of single product, long manufacturing cycle, etc., to reduce manufacturing costs, The effect of shortened manufacturing cycle and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

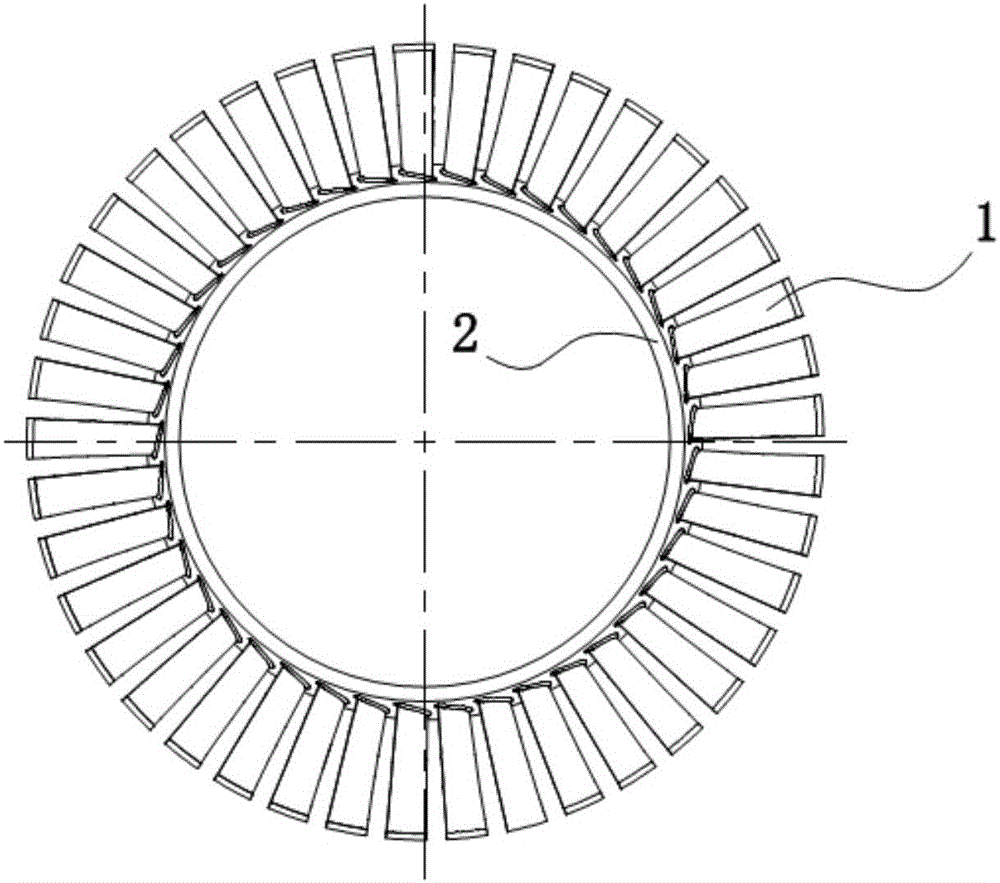

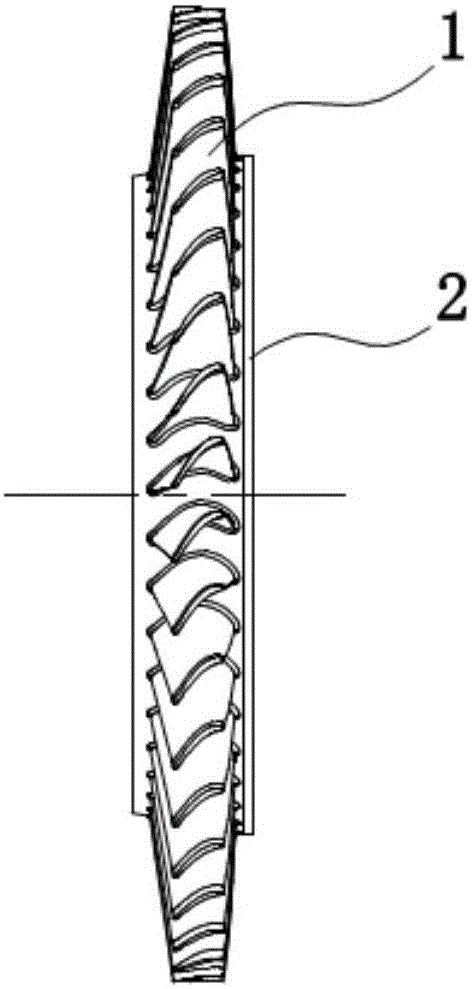

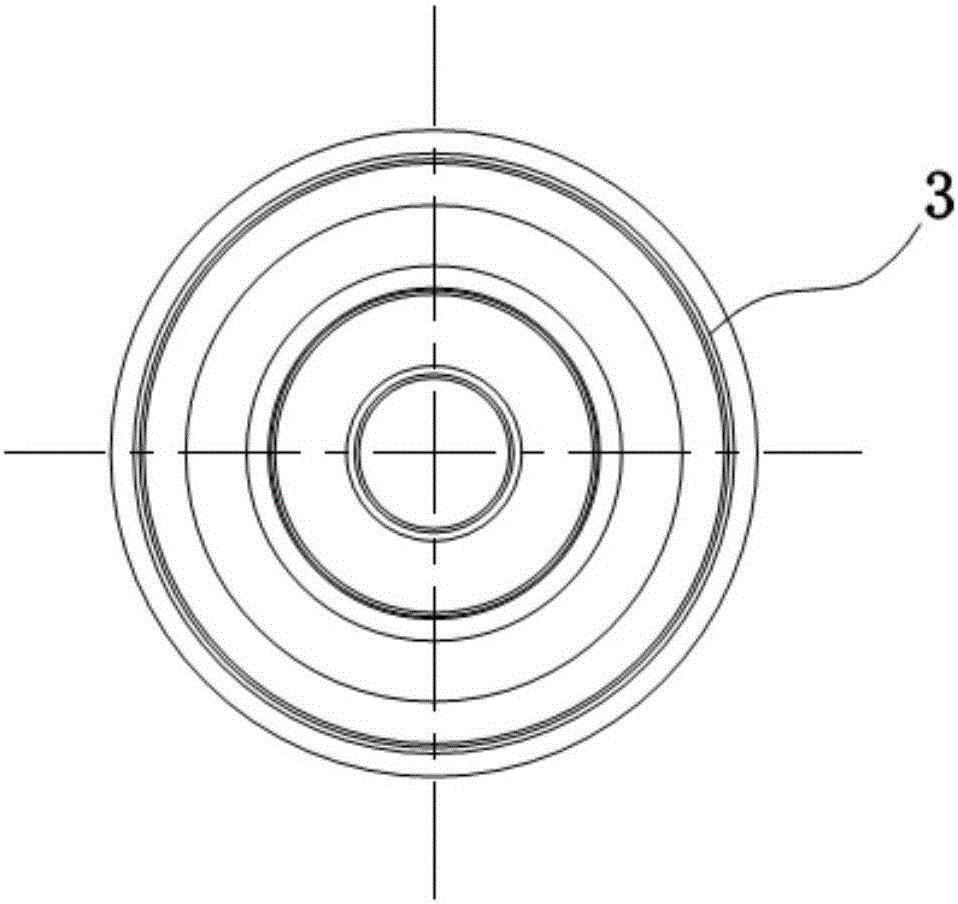

[0028] Such as Figure 1 to Figure 6 As shown, in the investment casting rapid prototyping method of this embodiment, the product includes a blade 1, a runner ring 2 and an inner ring 3, and the forming method includes the following steps:

[0029] The first step is to split the product into blade parts and non-blade parts. The blade part includes the runner ring 2 and the blade 1 installed on the runner ring 2, and the non-blade part is the inner ring 3;

[0030] In the second step, the blade part is printed into a wax model using a 3D printer. After the 3D printer prints, the supporting wax needs to be cleaned to ensure that there is no gap between the runner surface, the blade surface, and the transition angle between the blade 1 and the runner ring 3. The supporting wax remains; the two wax models need to be cooled to room temperature b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com