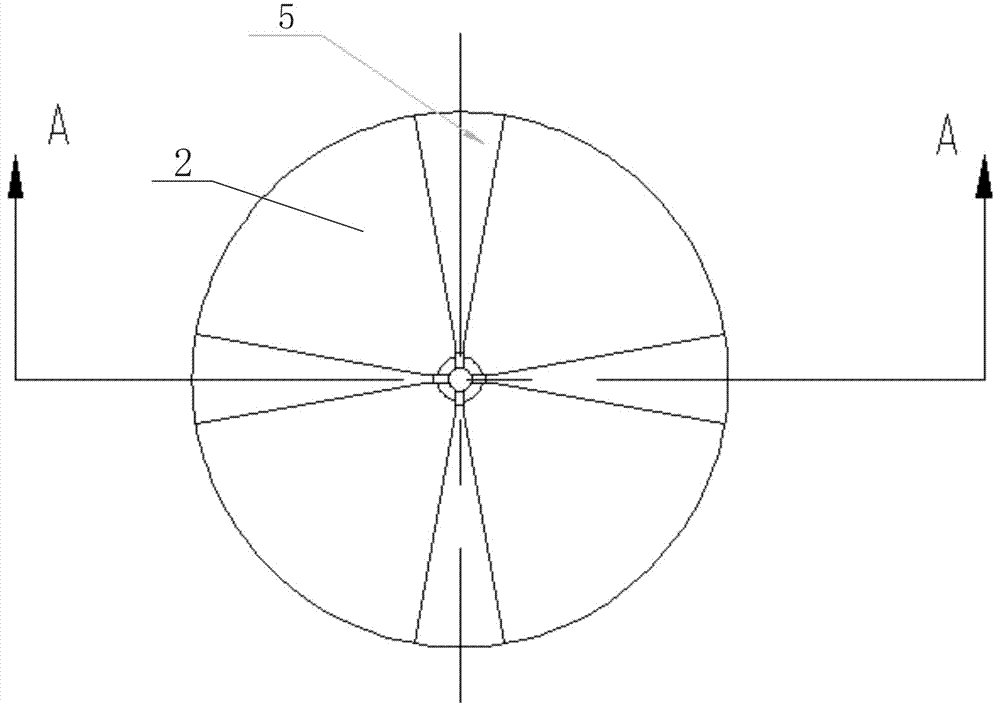

A gas atomizing nozzle for preparing metal powder

A gas atomization nozzle and metal powder technology, which is applied in the field of powder metallurgy, can solve problems such as difficult formation of high-pressure chambers, unstable air flow, and nozzle clogging, and achieve the effects of reducing energy loss, reducing costs, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

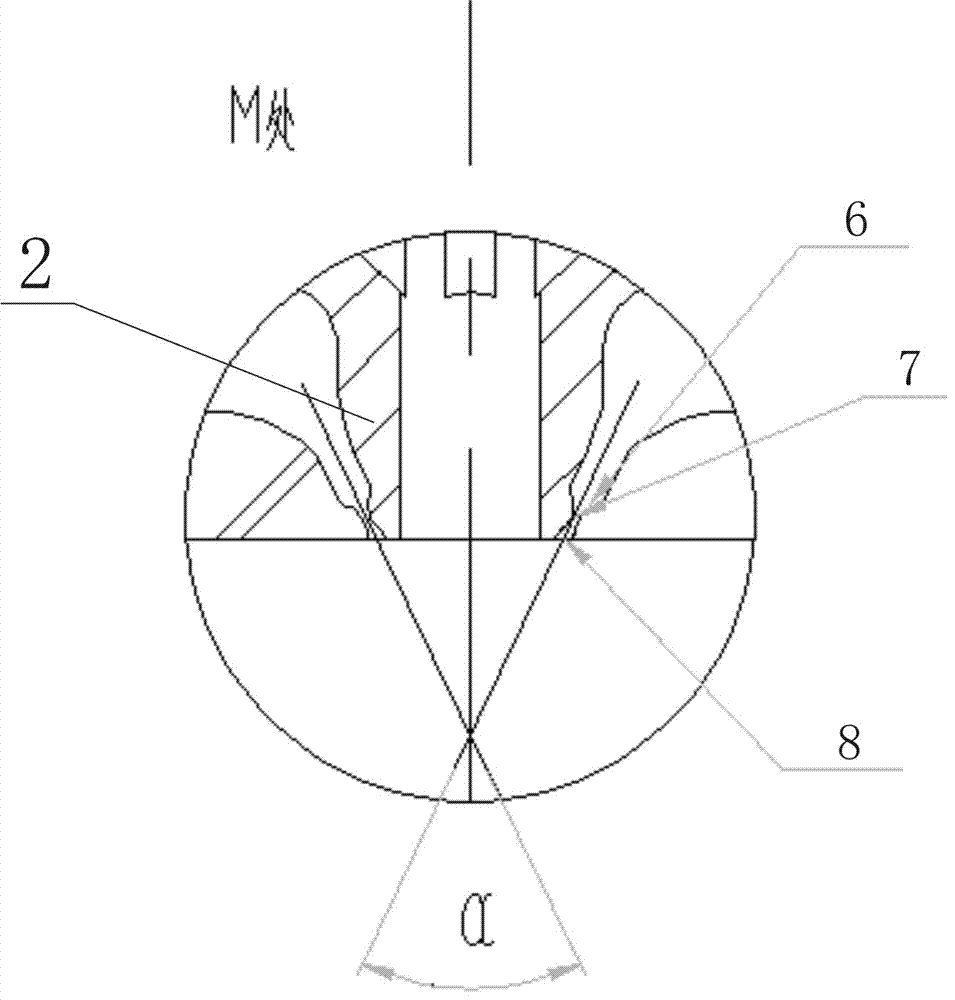

[0044] When working, a pure graphite crucible is used, and the angle α at the throat of the nozzle is selected as 52°. The ingredients are 100kg of copper and aluminum alloys (containing 0.6wt% aluminum), and the medium frequency induction melting is carried out after the system is vacuumed. After the charge begins to melt, a small amount of N2 is introduced. After the charge is completely melted, continue to heat up to 1500°C for atomization. When atomizing, the dynamic pressure of the pipeline is 1.4MPa, and the atomizing gas is N2. 10 furnaces were tested continuously, all of which were sprayed smoothly without clogging; the average yield of -100 mesh alloy powder was 89%, and -200 mesh alloy powder accounted for 78% of the -100 mesh powder.

Embodiment 2

[0046] When working, a pure graphite crucible is used, and the angle α at the throat of the nozzle is selected as 58°. The ingredients are 100kg of copper and aluminum alloy (containing 0.2wt% aluminum), and after the system is vacuumed, medium frequency induction melting is carried out. After the charge begins to melt, a small amount of N2 is introduced. After the charge is completely melted, continue to heat up to 1500°C for atomization. When atomizing, the dynamic pressure of the pipeline is 1.4MPa, and the atomizing gas is N2. 10 furnaces were tested continuously, all of which were sprayed smoothly without clogging; the average yield of -100 mesh alloy powder was 91%, and -200 mesh alloy powder accounted for 79% of the -100 mesh powder.

Embodiment 3

[0048] When working, use pure graphite crucible. The nozzle throat angle α is selected as 40°, and the material is a single electrolytic copper. After the system is vacuumed, medium frequency induction melting is carried out. After the charge is melted, continue to heat up to 1450°C for atomization. When atomizing, the dynamic pressure of the pipeline is 1.4MPa, and the atomizing gas is N2. 10 furnaces were tested continuously, all of which were sprayed smoothly without clogging; the average yield of -100 mesh copper powder was 90%, of which -200 mesh powder accounted for 80% of the -100 mesh powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com