Roller type polishing and dedusting all-in-one machine

An all-in-one, drum-type technology, used in surface polishing machine tools, grinding/polishing equipment, and machine tools suitable for grinding workpiece edges, etc., can solve problems such as uneven polishing of capsules, save handling time, and improve cleaning. degree, polishing uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

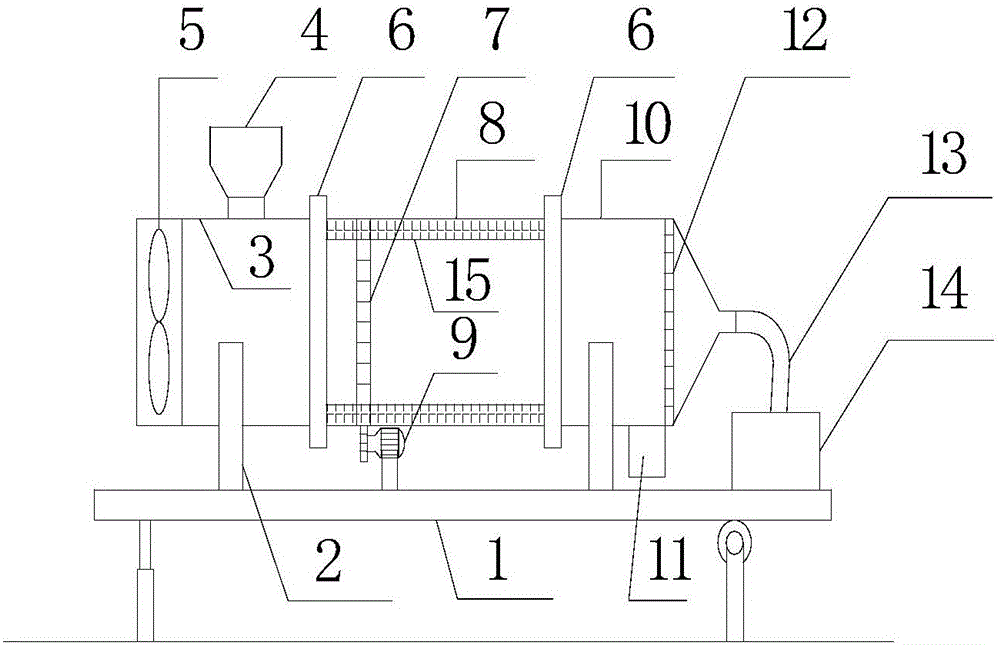

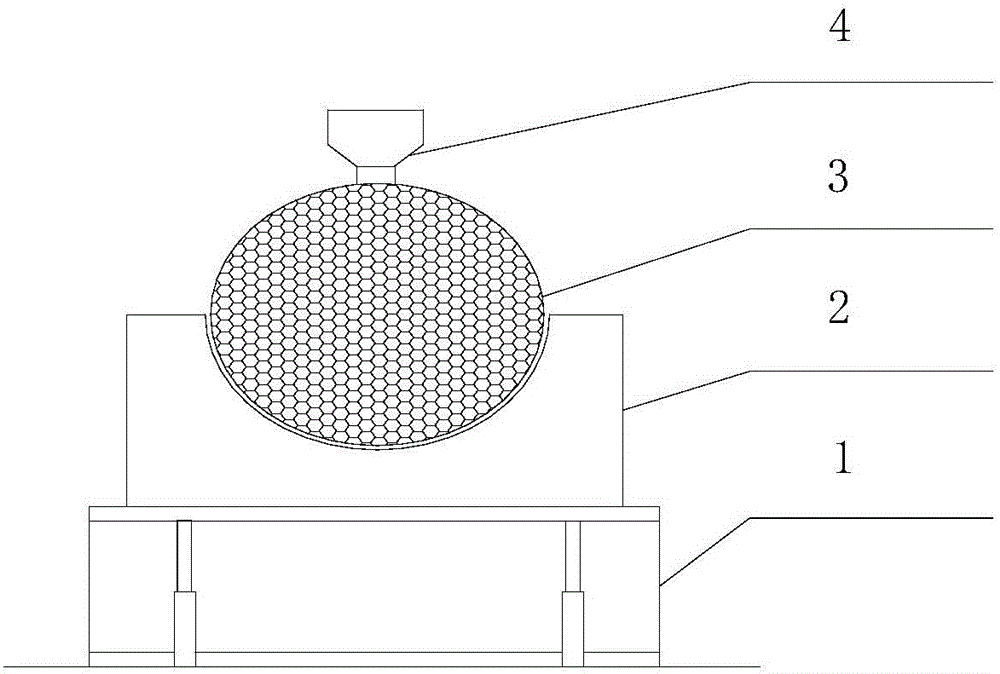

[0013] refer to figure 1 and figure 2 , a drum-type polishing and dust removal machine of the present invention, including a lifting platform 1, a support plate 2, a feeding cylinder 3, a hopper 4, an ion fan 5, a connecting device 6, a rotating track 7, a polishing cylinder 8, a motor 9, and a separation cylinder 10 , capsule discharge port 11, baffle plate 12, flexible pipe 13, vacuum cleaner 14 and polishing soft hair layer 15, described support plate 2 is installed on the lifting table 1, described feeding cylinder 3, polishing cylinder 8 and separating cylinder 10 Supported and fixed on the lifting table 1 by the support plate 2, the feeding cylinder 3, the polishing cylinder 8 and the separating cylinder 10 are connected through the connecting device 6, the hopper 4 is installed above the feeding cylinder 3, and the ion blower 5 is installed on the feeding cylinder. Inside the barrel 3, the rotating track 7 is provided on the outer surface of the polishing barrel 8, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com