Hydraulic control system and method for underground coal mine cement foaming machine

A hydraulic control system and cement foaming technology, applied in cement mixing devices, chemical instruments and methods, clay preparation devices, etc., can solve problems such as increased difficulty and operational danger, and achieve the effect of realizing automatic production and meeting explosion-proof requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

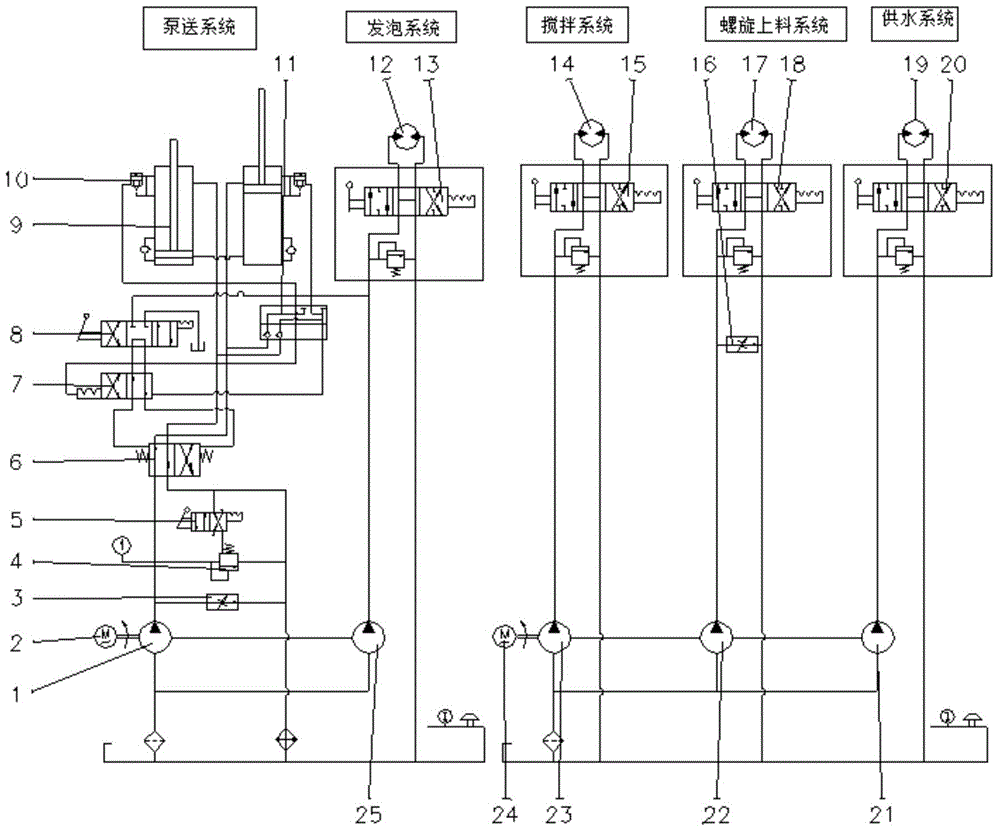

[0038] A hydraulic control system for an underground cement foaming machine in a coal mine, including a host motor 2 and a hydraulic station motor 24, the host motor 2 drives the first pump 1 and the second pump 25 through a coupling, and the first pump 1 and the second pump 25 Control the pumping system and the foaming system respectively; the motor 24 of the hydraulic station drives the third pump 23, the fourth pump 22 and the fifth pump 21 through the coupling, and the third pump 23, the fourth pump 22 and the fifth pump 21 are respectively controlled Stirring system, screw feeding system and water supply system; in the pumping system, when the stroke of the pumping cylinder 9 approaches the end, the control oil opens the logic valve 10 depending on the pressure difference, and the output control oil makes the pilot hydraulic valve 7 reversing, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com