Pressing explosion type dual-inner tube tire

A technology for inner tubes and tires, applied to tire parts, with independent inflatable cushions, transportation and packaging, etc., can solve the problems of enhanced safety tire production and use costs, to facilitate recycling, avoid direct collisions, run Return to normal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

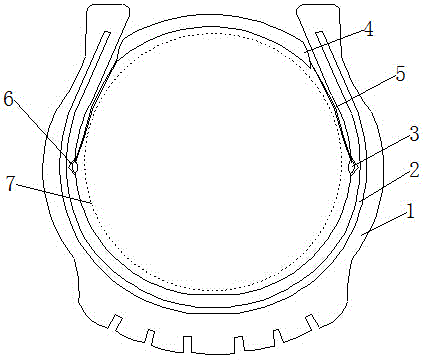

[0025] In the present embodiment, the decompression type double inner tube tire comprises a cover tire 1, a reinforcing rib 2, an inner tire 7, a spare tire 4, a connecting pipe 5 and a medicine bag 3, and the spare tire 4 is flatly arranged on the inside of the inner ring of the inner tire 7, and the medicine bag 3 Set in the tire 1, the medicine bag 3 is a sealed hollow structure provided with an air outlet, the air outlet of the medicine bag 3 is connected to the inflation port of the spare tire 4 through the connecting pipe 5, and the built-in material in the hollow structure of the medicine bag 3 includes azide salt Or at least one of ammonium nitrate.

[0026] In addition, the inner wall of the tire 1 can also be provided with trigger grooves 6 along the radial direction of the tire 1 in the shape of a concave groove into the tire, and the medicine package 3 is arranged in the trigger grooves 6 .

[0027] When the trigger groove 6 is provided, the trigger groove 6 may be...

Embodiment 2

[0030] In the present embodiment, the decompression type double inner tube tire comprises a cover tire 1, a reinforcing rib 2, an inner tire 7, a spare tire 4, a connecting pipe 5 and a medicine bag 3, and the spare tire 4 is flatly arranged on the inside of the inner ring of the inner tire 7, and the medicine bag 3 It is arranged in the outer tire 1 and is in the gap between the outer tire 1 and the inner tire 7. The medicine bag 3 is a sealed hollow structure provided with an air outlet. The air outlet of the medicine bag 3 is connected to the inflation port of the spare tire 4 through the connecting pipe 5. The built-in material in the hollow structure of package 3 includes at least one of azide salt or ammonium nitrate.

[0031] In addition, the inner wall of the tire 1 can also be provided with trigger grooves 6 along the radial direction of the tire 1 in the shape of a concave groove into the tire, and the medicine package 3 is arranged in the trigger grooves 6 .

[0032...

Embodiment 3

[0045] In this example, the raw material composition of ceramics is 100 parts of α-silicon carbide; 15 parts of boron carbide; Sintered ceramics are obtained after ball milling, spray drying, dry pressing, low temperature sintering, etc.

[0046] Among them, the low-temperature sintering is sintering under the protection of argon in a high-temperature vacuum furnace. The sintering temperature is 1870°C. After the temperature in the furnace reaches the sintering temperature, the heat preservation and sintering time is 1.3h.

[0047] In this example, a ceramic sample 100 was prepared, and the pass rate of the sintered product was 99%. After testing, the average density of the sample was greater than 98%, and the fracture toughness was greater than 6.5MPa / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com