Purifying process for quartz raw materials for ultra-clear glass

A technology of ultra-clear glass and quartz, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the bottleneck of large-scale use of ultra-clear glass, increase in production and demand, etc., to solve the risk of mining and purchasing raw materials, The effect of saving costs and saving enterprise test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The quartz raw material of this embodiment is a certain place in Lingyuan, and its chemical composition is as follows: SiO 2 Content 98.500%, Fe content 0.2661%. The specific purification process is as follows:

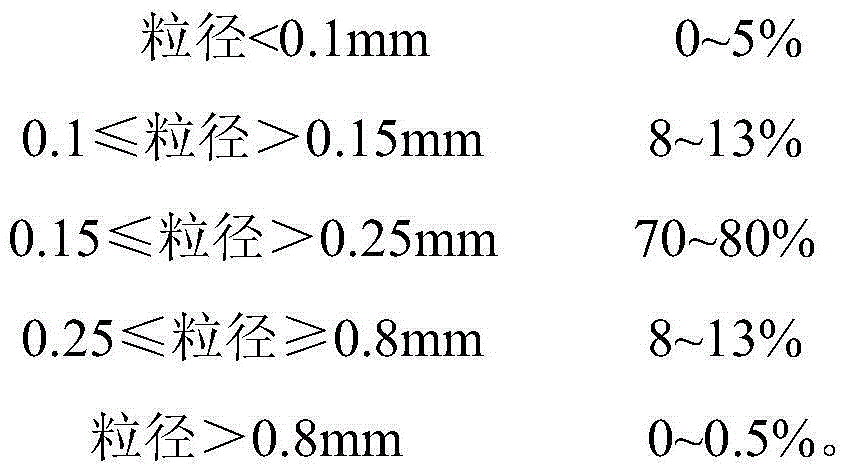

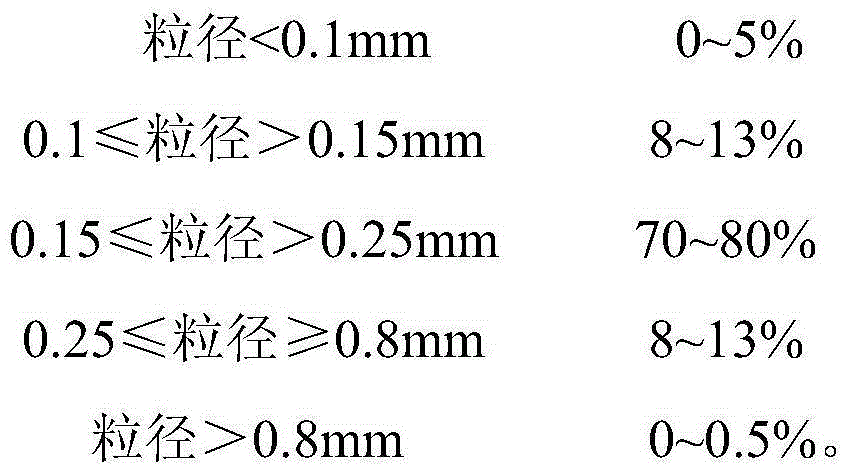

[0028] A. Coarse, medium and fine crushing of quartz raw materials from a place in Lingyuan to meet the particle size requirements of quartz raw materials for ultra-clear glass:

[0029]

[0030] B. The crushed quartz material is magnetically separated by a high-intensity magnetic field with a strong NdFeB magnetic rod, and the magnetic field strength is 3350GS.

[0031] C. The quartz material after magnetic separation is put into a crucible and calcined in a muffle furnace at a heating rate of 5°C / min, and kept at 470°C for 1h.

[0032] D. Put the calcined quartz material into the mixed acid pickling solution for acid leaching. Take 50g of calcined material and put it into a container filled with inorganic acid pickling solution. The volume (ml) ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com