Method for curing artificial stone through microwave heating

A microwave curing and microwave heating technology, applied in the field of microwave applications, can solve the problems of large-scale artificial stone curing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

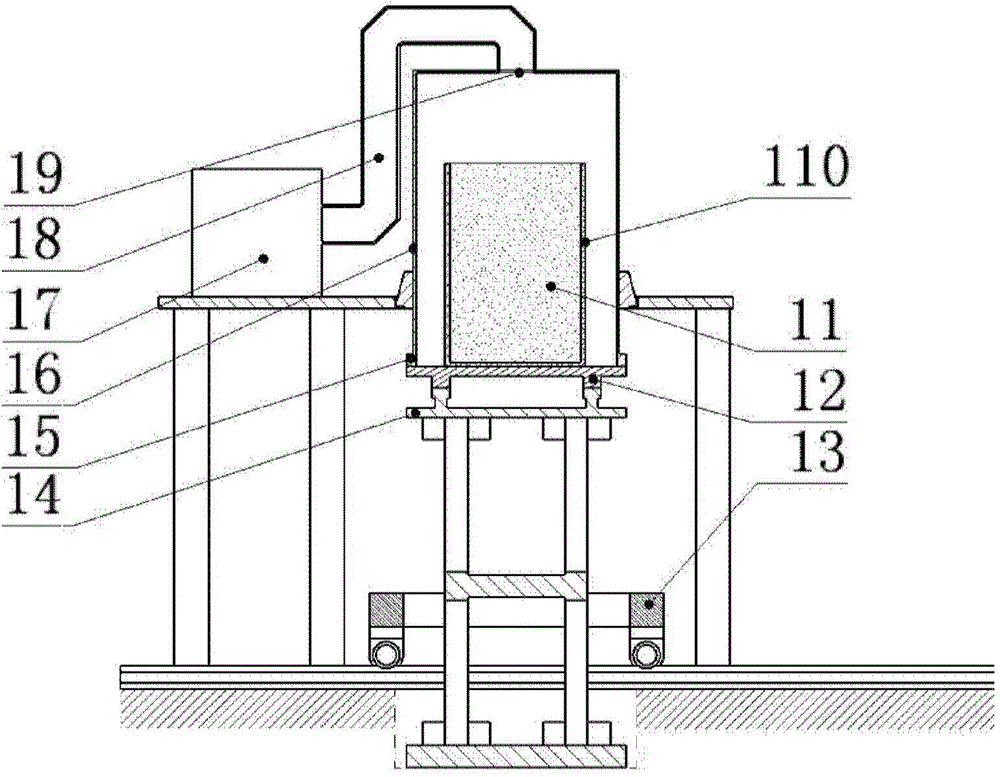

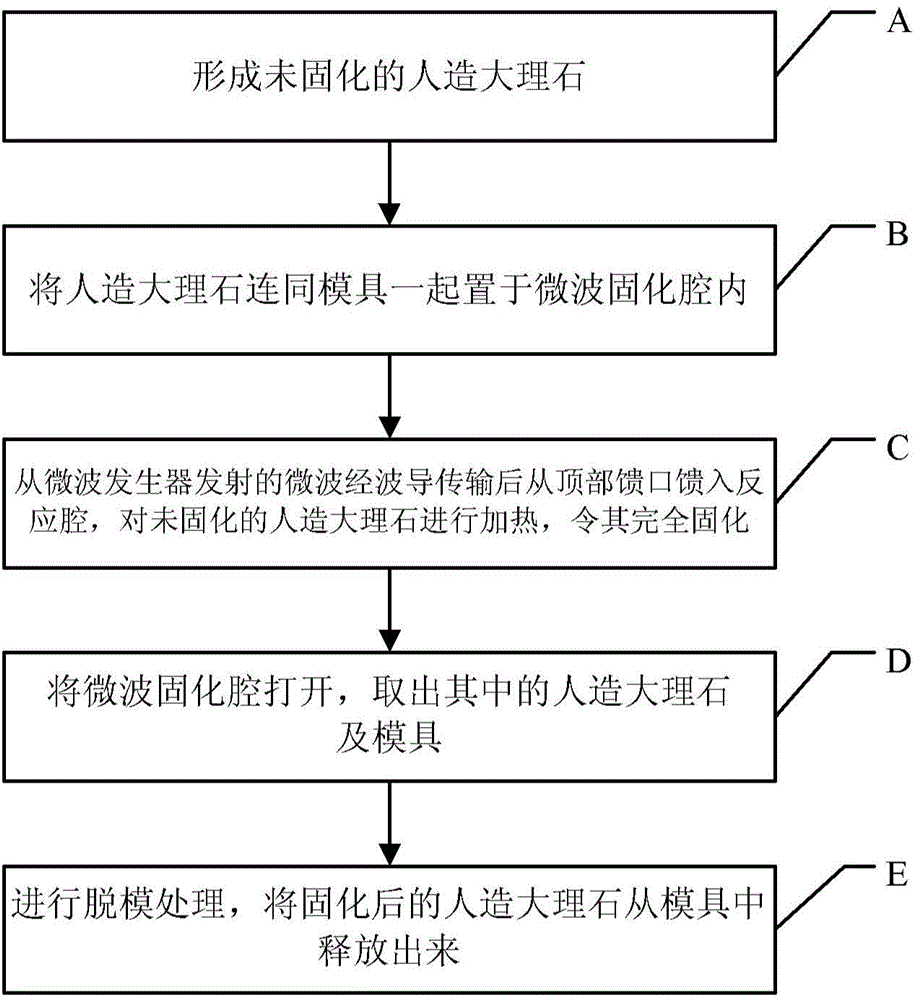

[0022] In the present invention, the artificial marble in the mold (or inner mold) is directly irradiated with microwaves of a specific frequency (between 300 and 1120 MHz, typically 915 ± 10 MHz) that have good penetrability to artificial marble, causing the internal The frictional movement between molecules converts microwave energy into kinetic energy and finally heat energy, so that the artificial marble is heated rapidly and the curing time is greatly shortened.

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0024] It should be noted that, in the following two embodiments, artificial marble blocks are used as an example for illustration. The artificial marble here refers to calcium carbonate, silicon dioxide or aluminum hydroxide powder as the main filler, unsa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com