The synthetic method of 2,3,3,3-tetrafluoropropene

A technology of tetrafluoropropene and synthesis method, applied in halogen substitution preparation, organic chemistry and other directions, can solve problems such as high price and low yield of target product, and achieve the effects of low production cost, high yield and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

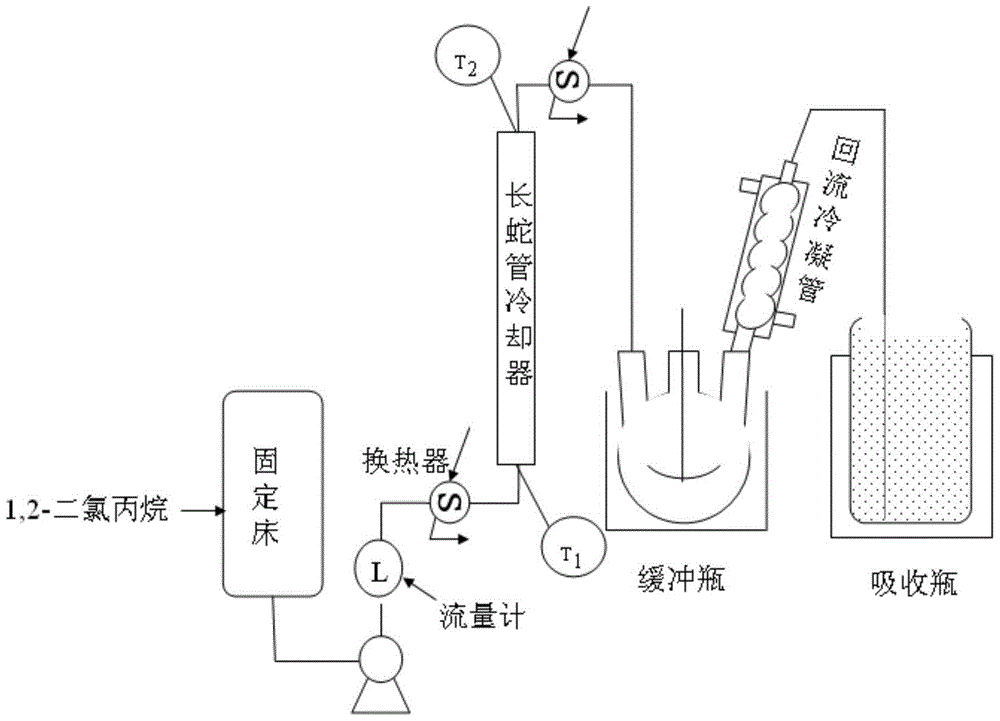

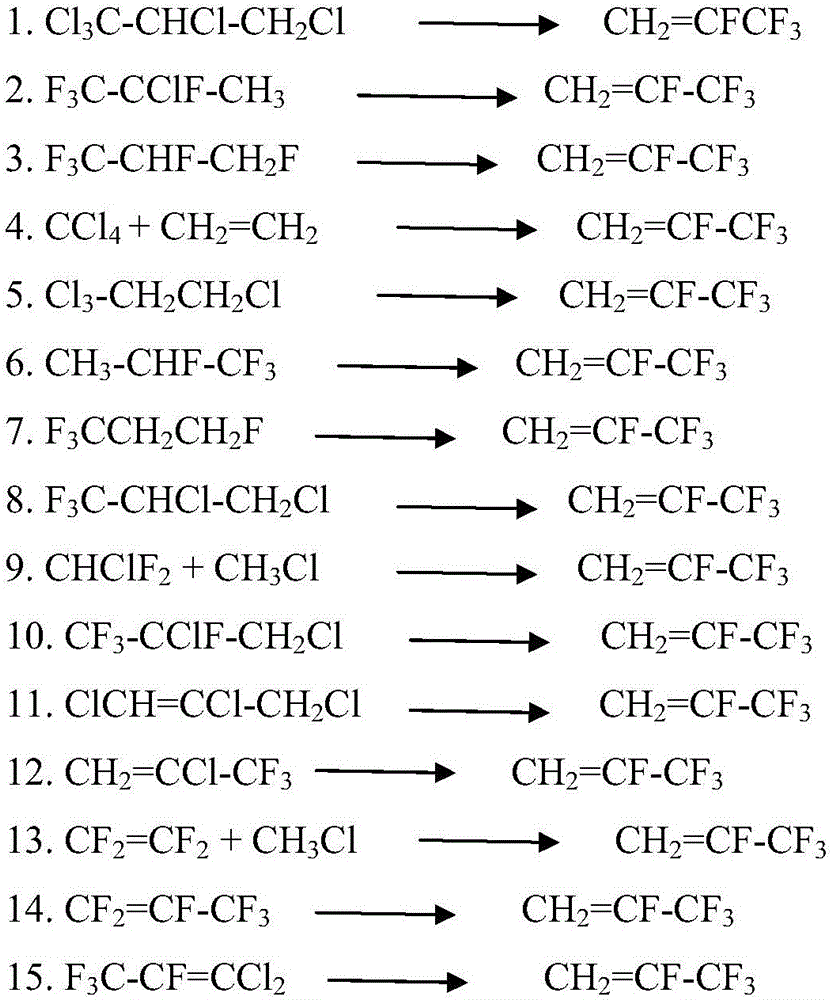

Method used

Image

Examples

example 1

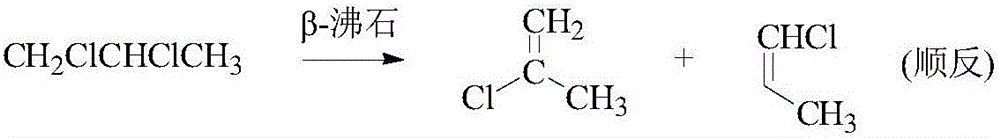

[0020] Example 1: Preparation of 2-chloropropene

[0021] Add 200 mL of β-zeolite to the fixed bed with a diameter of 25×1200 mm, and seal both ends with quartz stones. Preheat the fixed bed to 240°C, then add 1,2-dichloropropane at a rate of 0.5L / h, preheat to 180°C through the preheater, enter the fixed bed and crack at 240°C, and the cracked gas is cooled by the cooler Enter the buffer bottle, condense the cracked product into a liquid through the reflux condenser on the buffer bottle, and the non-condensable hydrogen chloride gas comes out from the top of the condenser and passes into the water to become hydrochloric acid. After 2 hours of continuous cleavage, 950g of liquid was obtained, which was sampled and analyzed (chromatographic column SE-30, column temperature 30°C, kept for 3 minutes, then raised to 150°C at 10°C / min, vaporization temperature 150°C, detector temperature 150°C) , 1,2-dichloropropane content 45.5%, cis 1-chloropropene 12%, trans 1-chloropropene 12%...

example 2

[0022] Example 2: By the same method and proportioning, the pyrolysis temperature was increased to 260°C, and 830 g of liquid was obtained after continuous pyrolysis for 2 hours, which was sampled and analyzed. The content of 1,2-dichloropropane is 32%, cis-1-chloropropene is 11%, trans-1-chloropropene is 11%, 2-chloropropene is 35.5%, and 3-chloropropene is 11.5%. The decrease in output means that there is polymerization or carbonization. When the fixed bed is disassembled, carbonization is found, so the cracking temperature should be less than 260°C.

example 3

[0023] Example 3: Preparation of 2,3,3,3-tetrachloropropene

[0024] Take out the β-zeolite, replace it with 200mL granular ferric chloride, heat it up to 220°C, preheat 1mol of 2-chloropropene and 3mol of chlorine gas at 0.5L / h to 160°C and 120°C respectively through a preheater, and then After being mixed by a static mixer, it is passed into a fixed bed, and the residence time is 20 seconds. The gas that comes out is cooled by a 20-meter long coil cooler, and the non-condensable hydrogen chloride gas goes out from the top of the cooler and is absorbed by water to be hydrochloric acid to obtain 105 g of liquid. Sampling analysis (chromatographic column SE-30, column temperature 80°C, keep for 3 minutes, then rise to 250°C at 30°C / min, vaporization temperature 250°C, detector temperature 250°C), 2,3,3,3-four Chloropropene 82%, 1,2,2,3,3,3-hexachloropropane 18%, 71-72°C fraction 2,3,3,3-tetrachloropropene was collected by vacuum fractional distillation to obtain 140g of produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com