A kind of annular adhesive and its synthesis method

A synthesis method and adhesive technology, applied in the direction of adhesives, etc., can solve the problems such as the reduction of the adhesion of the addition type silicone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

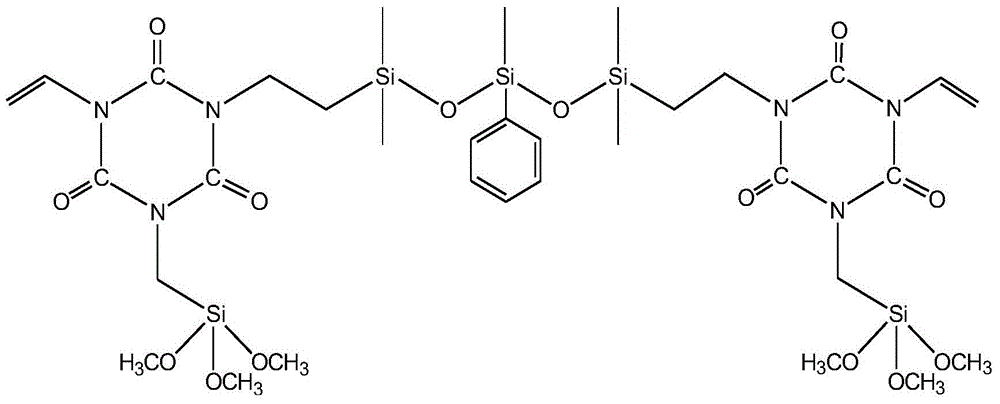

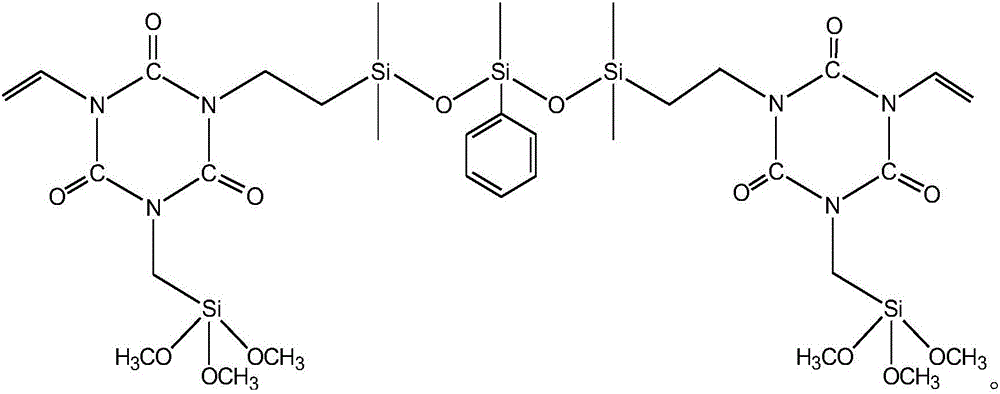

Image

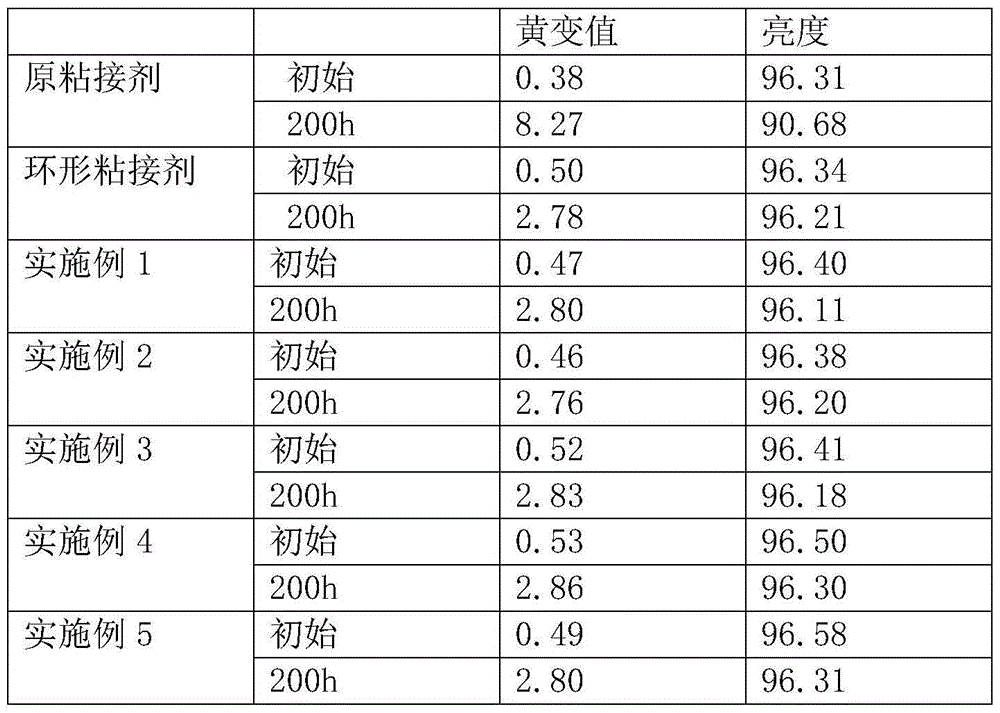

Examples

Embodiment 1

[0011] Keep the temperature of the oil bath at 70°C, add 50 grams of triallyl isocyanurate and 0.002 grams of platinum catalyst into a three-necked flask equipped with mechanical stirring, a condenser, and a constant pressure funnel, blow in nitrogen protection, and open the After stirring, 24 g of 1,1,3,5,5-pentamethyl-3-phenyltrisiloxane was slowly added dropwise into the three-necked flask, and the dropwise addition was completed within 0.5 hours, and the reaction was stirred for 3 hours. Then 24 g of trimethoxysilane was added dropwise into the three-necked flask, and the dropwise addition was completed within 0.5 hours. The stirring reaction was continued for 4 hours, the stirring reaction was stopped, and the low boilers were removed by distillation under reduced pressure. Cool down to room temperature, add 3 grams of activated carbon, stir and adsorb at room temperature for 12 hours, and obtain 84 grams of ring-shaped adhesive after filtration.

Embodiment 2

[0013] Keep the temperature of the oil bath at 80°C, add 50 grams of triallyl isocyanurate and 0.0025 grams of platinum catalyst into a three-necked flask equipped with mechanical stirring, a condenser, and a constant pressure funnel, blow in nitrogen protection, and open the After stirring, 27 g of 1,1,3,5,5-pentamethyl-3-phenyltrisiloxane was slowly added dropwise into the three-necked flask, and the dropwise addition was completed within 0.5 hours, and the reaction was stirred for 3 hours. Then add 30 g of trimethoxysilane dropwise into the three-necked flask, and the dropwise addition is completed within 0.5 hour, and the stirring reaction is continued for 4 hours, then the stirring reaction is stopped, and the low boilers are removed by distillation under reduced pressure. Cool down to room temperature, add 3 grams of activated carbon, stir and adsorb at room temperature for 12 hours, and obtain 90 grams of ring-shaped adhesive after filtration.

Embodiment 3

[0015] Keep the temperature of the oil bath at 75°C, add 55 grams of triallyl isocyanurate and 0.003 grams of platinum catalyst into a three-necked flask equipped with mechanical stirring, a condenser, and a constant pressure funnel, blow in nitrogen protection, and open the After stirring, slowly drop 28 grams of 1,1,3,5,5-pentamethyl-3-phenyltrisiloxane into the three-necked flask, and complete the dropwise addition within 0.5 hours, and stir for 3 hours to react. Then 32 g of trimethoxysilane was added dropwise into the three-necked flask, and the dropwise addition was completed within 0.5 hours, and the stirring reaction was continued for 4 hours, then the stirring reaction was stopped, and the low boilers were removed by distillation under reduced pressure. Cool down to room temperature, add 3 grams of activated carbon, stir and adsorb at room temperature for 12 hours, and obtain 102 grams of ring-shaped adhesive after filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com