Organic silicon adhesive for packaging LED (light-emitting diode) chip

A technology of LED chips and silicone adhesives, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., to achieve the effect of excellent hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

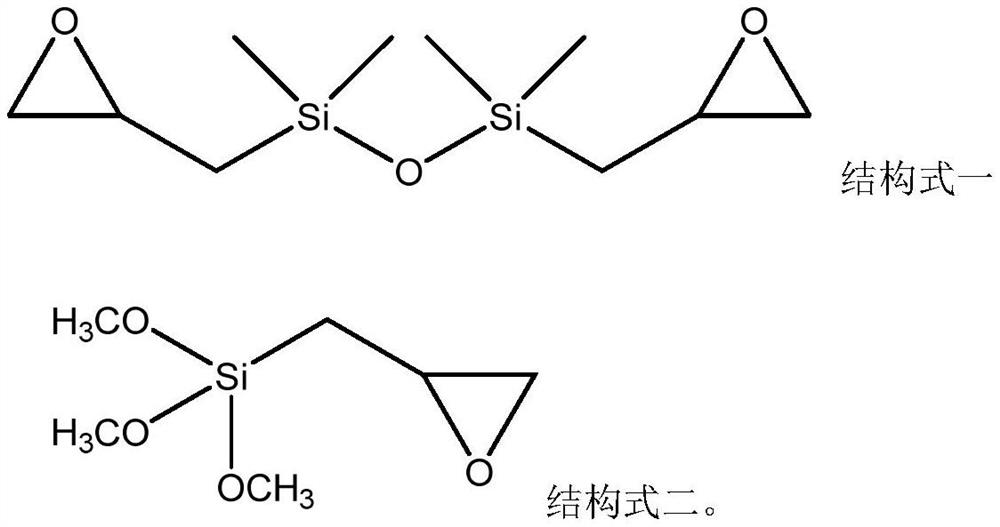

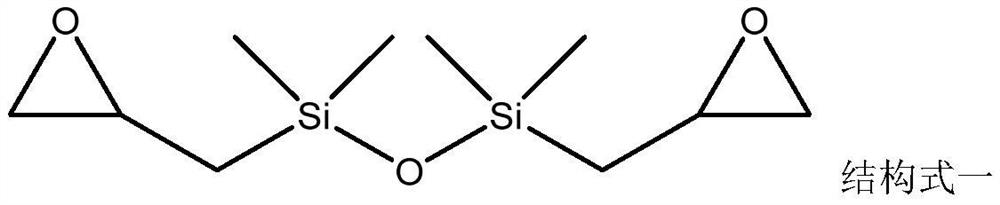

[0023] Methylphenyl vinyl silicone resin 800g (j+k+l=20; Wherein: j=5, k=5, l=10), platinum catalyst chloroplatinic acid alcohol solution (platinum content is 3000ppm) 1g, ring Oxygen-modified binder 50g Structural formula one, methylphenyl hydrogen-containing silicone resin 60ga=2, b=6, c=6, epoxy acrylic acid modified hydrogen-containing silicone oil 30g (n=10, m=10), inhibition Agent ethynyl cyclopentanol 1g.

Embodiment 2

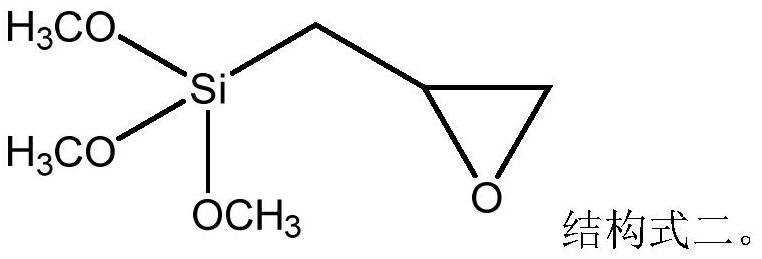

[0025] Methylphenyl vinyl silicone resin 950g (j+k+l=14; Wherein: j=1, k=1, l=12), platinum catalyst agent platinum-vinylsiloxane complex (platinum content 3000ppm) 3g, epoxy modified adhesive 150g structural formula 2, component B includes 70g of methyl phenyl hydrogen-containing silicone resin (a=2, b=3, c=6), epoxy acrylic acid modified hydrogen-containing Silicone oil 40g (n=20, m=20), inhibitor tetramethyltetravinylcyclotetrasiloxane 2g.

Embodiment 3

[0027] Methylphenyl vinyl silicone resin 900g (j+k+l=18; wherein: j=4, k=4, l=10), catalyst platinum olefin complex (platinum content is 3000ppm) 2g, epoxy modified 100g structural formula 1, component B includes 70g of methylphenyl hydrogen-containing silicone resin (a=2, b=6, c=6), 35g of epoxy acrylic modified hydrogen-containing silicone oil (n=10, m =20), inhibitor ethynyl cyclohexanol 1.5g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com