Impact damage rock sample preparation and assay method based on SHPB test

An impact damage and rock sample technology, applied in the field of impact damage rock sample preparation and measurement based on SHPB test, can solve the problems of inaccurate quantification and rock dynamic damage, and achieve the effect of comprehensive and reliable test data and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

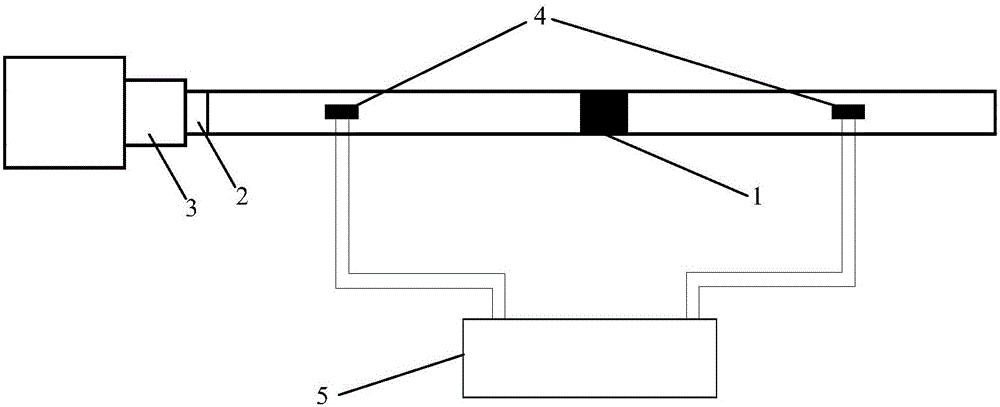

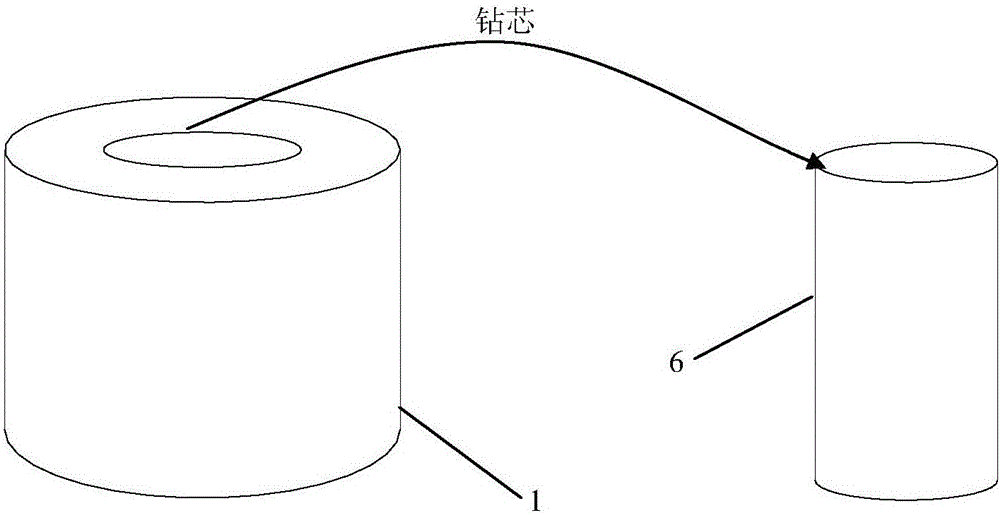

[0028] Embodiment 1: The rock sample preparation method for determining the damage degree includes: preparation of impact damaged rock samples, mesoscopic tests on impact damaged rock samples and macroscopic tests on impact damaged rock samples.

[0029] 1. The preparation of impact damaged rock samples includes the following steps:

[0030] a. Make multiple cylindrical rock samples with a diameter and length of 100mm, carefully polish the two end faces of the samples so that the non-parallelism and non-perpendicularity are less than 0.02mm, and apply a layer of butter to reduce the friction;

[0031] b. Use the SHPB device with a rod diameter of 100mm for experimental pre-impact, fix the position of the impact rod in the high-pressure gas chamber, select the appropriate air pressure for impact loading, and the air pressure value corresponding to the critical failure state where the specimen is broken and fragments are peeled off Determined as the critical pressure;

[0032]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com