Industrial robot remote service and monitoring system

An industrial robot and remote service technology, applied in the field of industrial robot remote service and monitoring systems, can solve the problems of weak data security, lack of confidentiality, and low capacity for cluster management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of technical personnel.

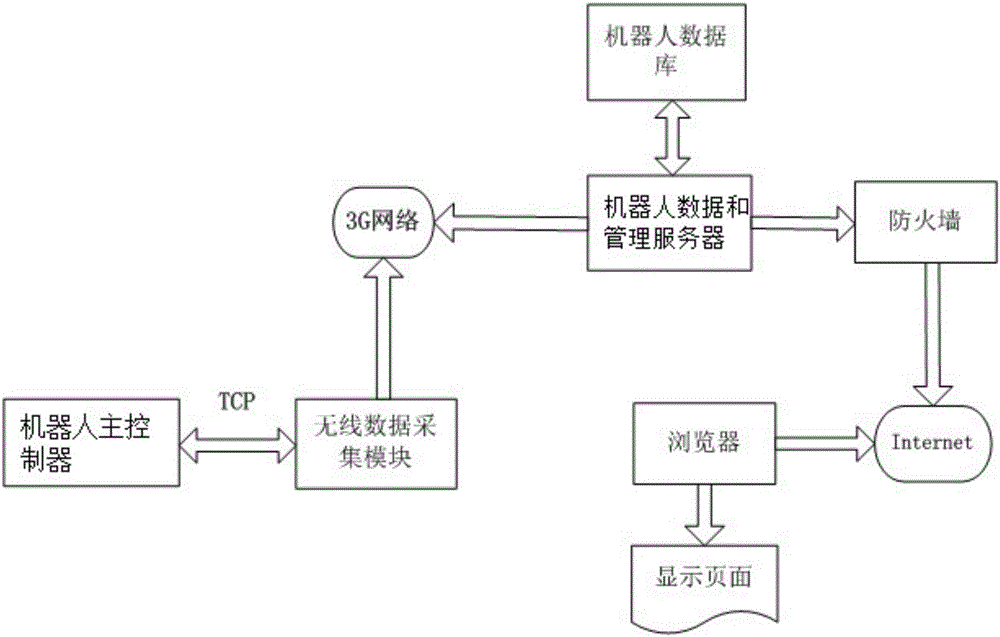

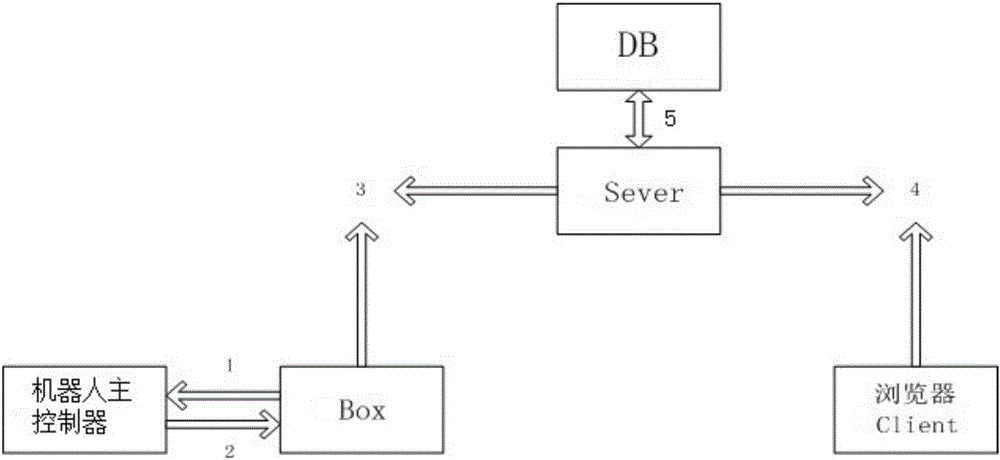

[0017] Such as figure 1 as shown, figure 1 DB in stands for robot database. Specific embodiments of the present invention are as follows:

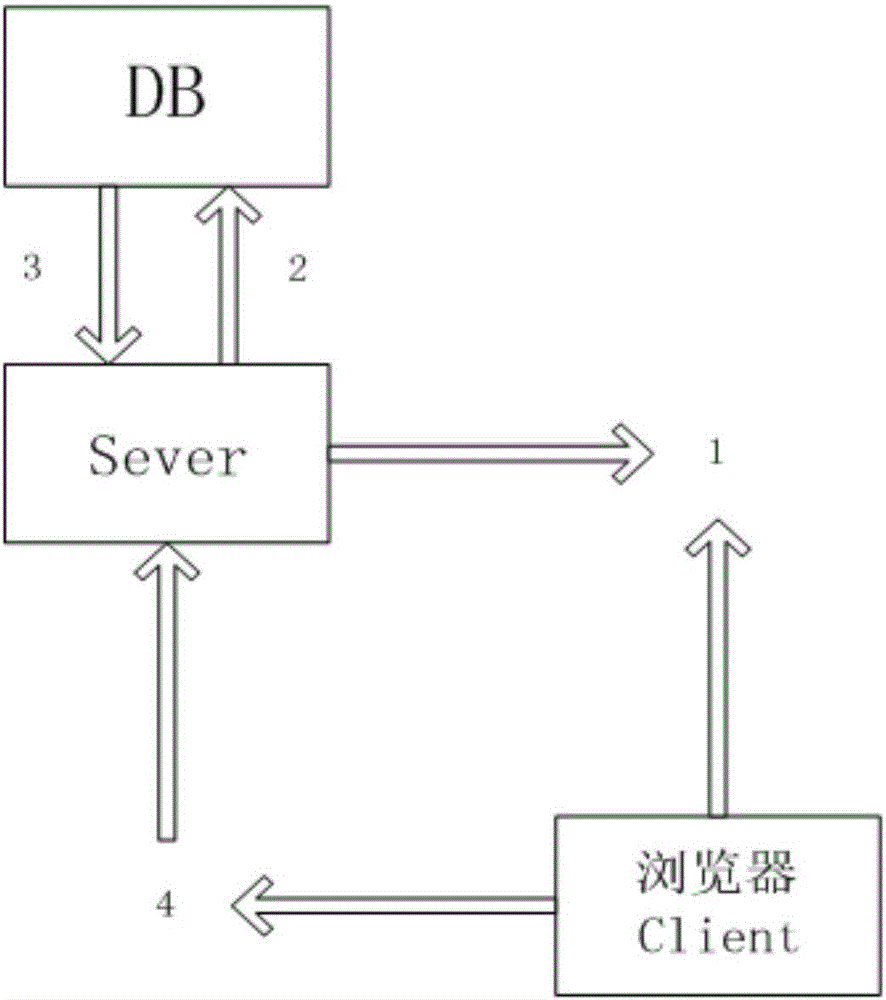

[0018] An industrial robot remote service and monitoring system, including a hardware data collector Box, a robot data and management server Server, and a WEB page access server, the hardware data collector Box sends a data request to the robot master controller in a polling manner, The main controller of the robot receives the request and responds and returns the data to the hardware data collector Box, which periodically sends the data to the robot data and management server Server t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com