Microchannel plate and preparation method thereof

A micro-channel plate and micro-channel technology, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of output, weak spatial resolution of micro-channel plates, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, characteristics and effects of a microchannel plate and its preparation method according to the present invention will be described below in conjunction with the preferred embodiments. , detailed below.

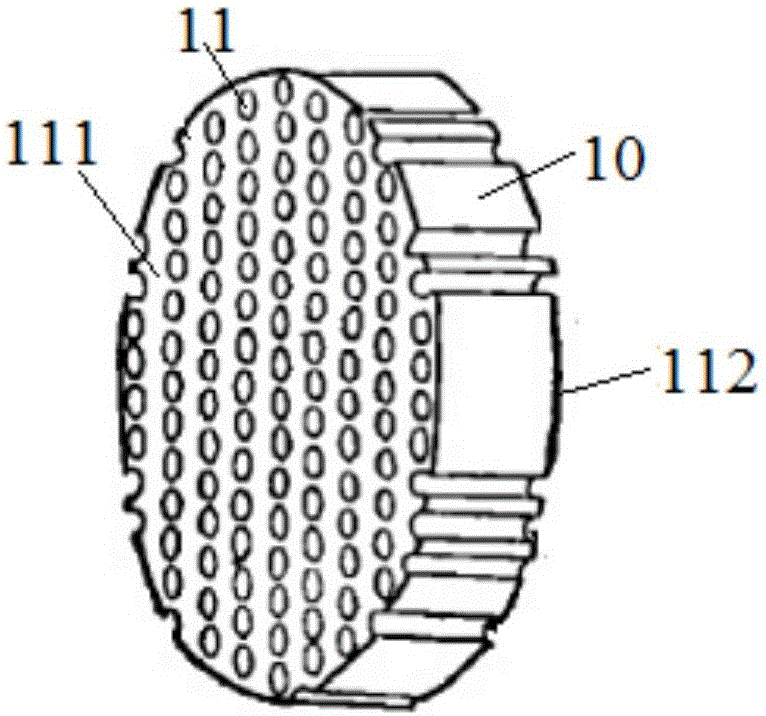

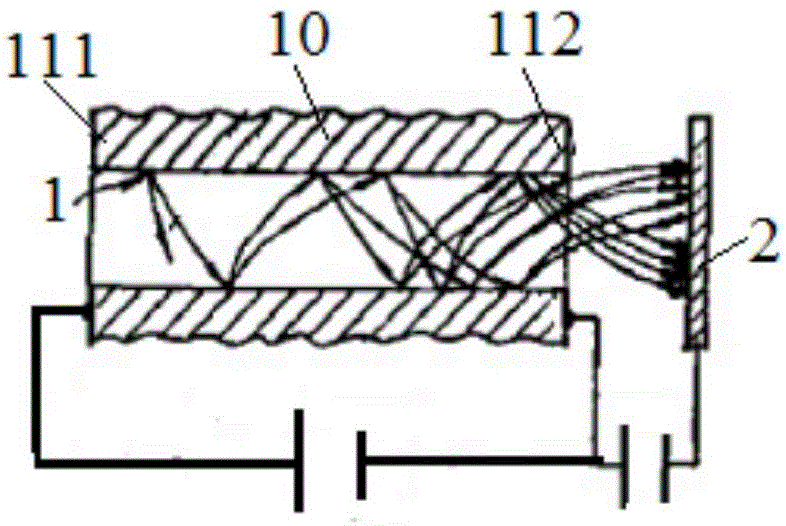

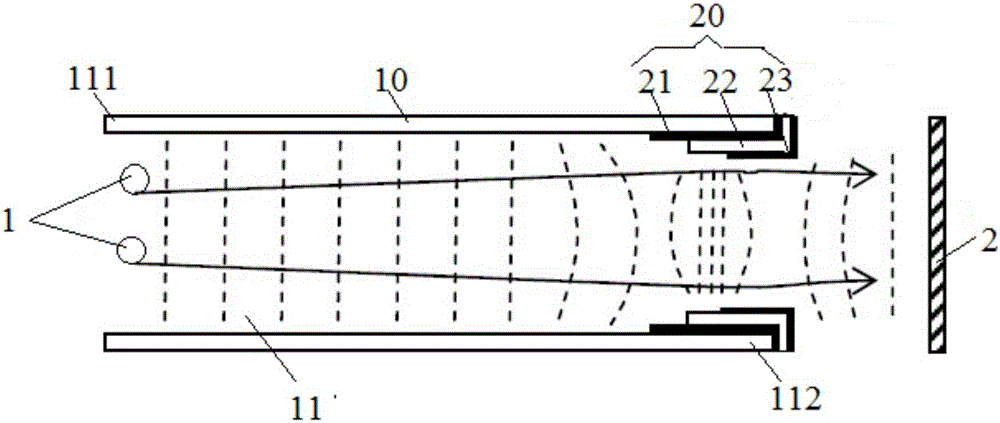

[0047] Such as figure 1 As shown, the structure schematic diagram of the microchannel plate provided by the first embodiment of the present invention. Specifically, combine figure 1 , figure 2 and image 3It can be known that the micro-channel plate provided in this embodiment includes: a substrate 10 and at least one thin film 20 . Substrate 10 is provided with a plurality of micro-channels 11, and one end of micro-channels 11 is input end 111, and the end face of described input end 111 is coated with conductive material (as nickel-chromium alloy, nichrome-iron or chromium etc. conductive material), d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com