Piezoelectric transformer based on single crystal surface cutting mode

A technology of piezoelectric transformer and single crystal surface, applied in the field of piezoelectric transformer, can solve the problems of low electromechanical coupling efficiency, low coupling efficiency, high driving voltage, etc., and achieve the effects of low operating frequency, high power density, and low calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following the described embodiment.

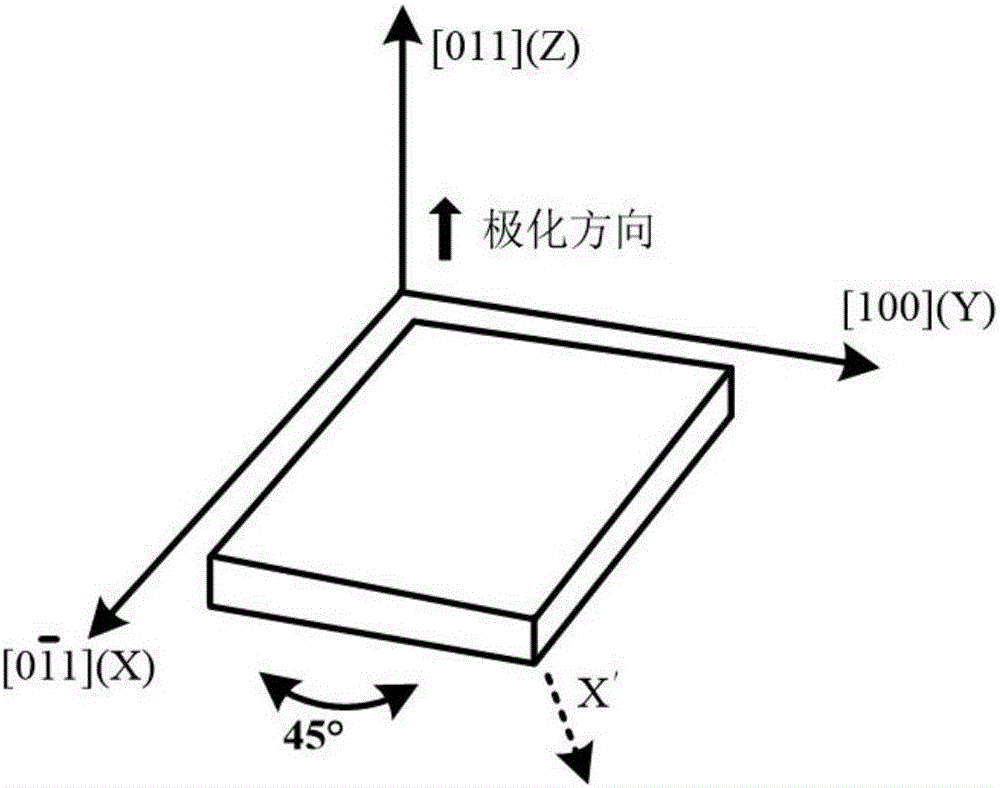

[0016] figure 1 It is a schematic diagram of the coordinates of the piezoelectric single crystal in the face-cut mode. The length, width and thickness directions of the face-cut mode piezoelectric single crystal are along the [011] c , [100] c and [011] c direction, polarization direction [011] c is defined as the coordinate axis Z, [011] c and [100] c The directions are defined as coordinate axes X and Y, respectively. All material constant symbols are based on this orthogonal coordinate system.

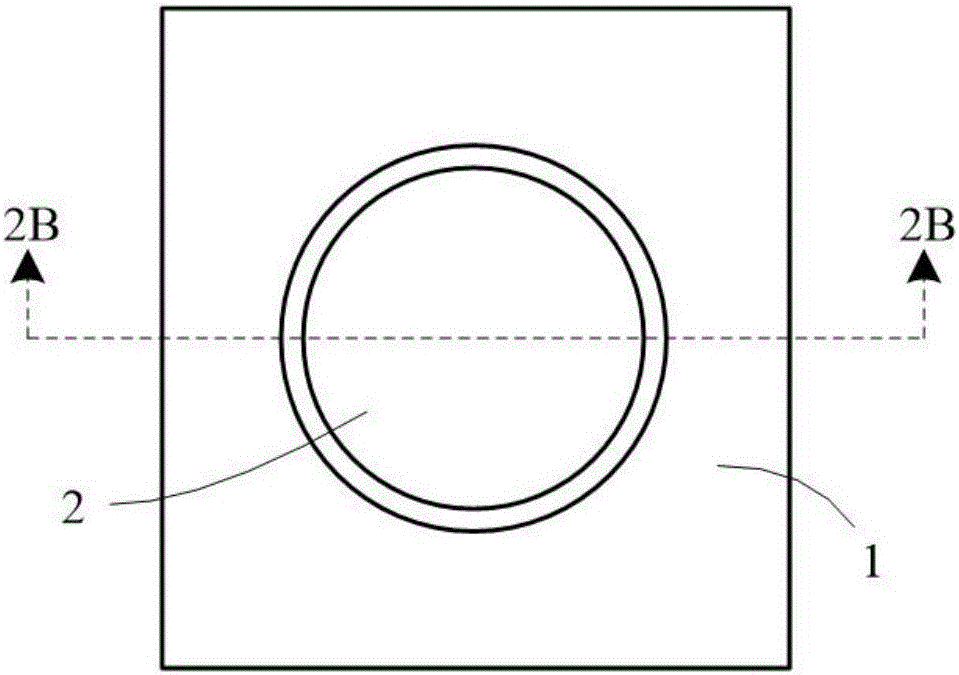

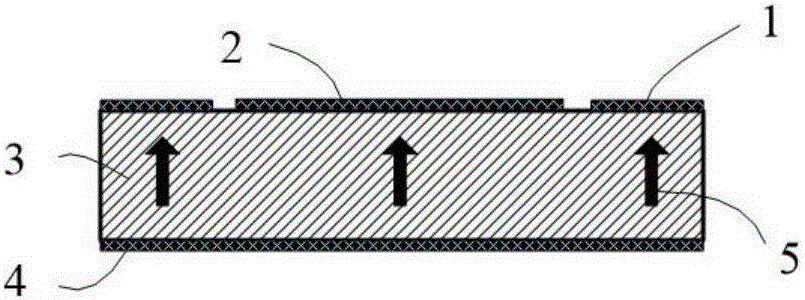

[0017] Such as Figure 2 to Figure 5 As shown, the piezoelect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com