S-waveband communication-in-motion double-frequency circularly polarized micro-strip antenna and array thereof

A technology of microstrip antenna and communication in motion, which is applied to the combination of antenna units, antennas, and radiating element structures with different polarization directions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

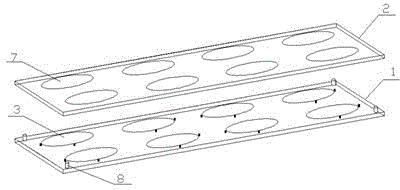

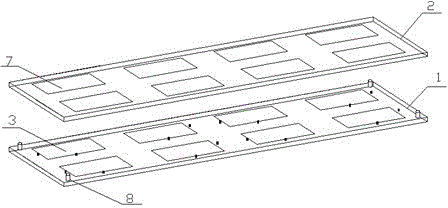

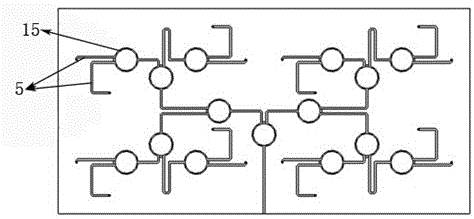

[0037] Specific implementation mode one: to combine figure 1 , image 3 , Figure 4 , Figure 5 with Image 6, the S-band dual-frequency circularly polarized microstrip antenna array of the present invention is made of a three-layer PTFE plate 1 etched with a metal floor 4, a radiation metal sheet 3, and a feed network 9 and a single layer of a parasitic metal sheet 7 etched with The PTFE plate 1 is supported and connected by nylon column pins 8 . The microstrip feeder 5 and the radiating metal sheet 3 are electrically connected through the metal via 6; the opening 10 corresponding to the center axis of the metal via 6 on the floor has an aperture larger than that of the metal via 6, and the metal floor 4 is electrically insulated from the metal via 6. The central axes of the corresponding radiating metal sheets 3 and the parasitic metal sheets 7 coincide respectively. The radius R3 of the metal via 6 = 0.8 mm; the radius R4 of the opening 10 corresponding to the centra...

specific Embodiment approach 2

[0039] Specific implementation mode two: combine figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , the S-band dual-frequency circularly polarized microstrip antenna array of the present invention is made of a three-layer PTFE plate 1 etched with a metal floor 4, a radiation metal sheet 3, and a feed network 9 and a single layer of a parasitic metal sheet 7 etched with The PTFE plate 1 is supported and connected by nylon column pins 8 . The microstrip feeder 5 and the radiating metal sheet 3 are electrically connected through the metal via 6; the metal floor 4 corresponds to the opening 10 at the central axis of the metal via 6, and the aperture is larger than the diameter of the metal via 6. The metal floor 4 and the metal via 6 are electrically connected. insulation. The central axes of the corresponding radiating metal sheets 3 and the parasitic metal sheets 7 coincide respectively. The radius R3 of the metal via 6 = 0.8 mm; the radius R4 of the opening 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com