Device and method for detecting membrane damage of a flat membrane module

A detection device and detection method technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation and other directions, can solve the problems of inability to realize online detection, small application range, insensitive detection, etc. The effect of online detection and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

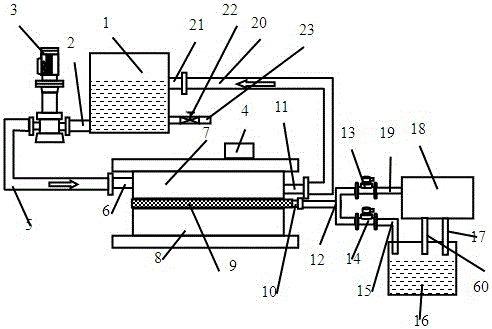

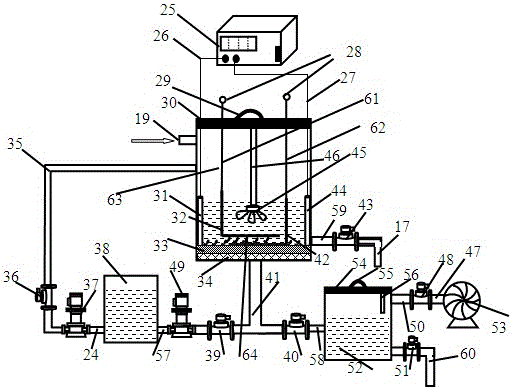

[0027] see figure 1 , is a schematic diagram of the overall structure of the membrane damage detection device of the flat membrane module of the present invention, the flat membrane module has a flat membrane 9, an upper splint 7 and a lower splint 8, and the flat membrane 9 is located between the upper splint 7 and the lower splint 8 to realize the filtration of the stock solution , the left side of the upper splint 7 is provided with a flat membrane module inlet 6, the right side is provided with a flat membrane module outlet 11, and the right side of the flat membrane 9 is provided with a flat membrane filtrate outlet 10.

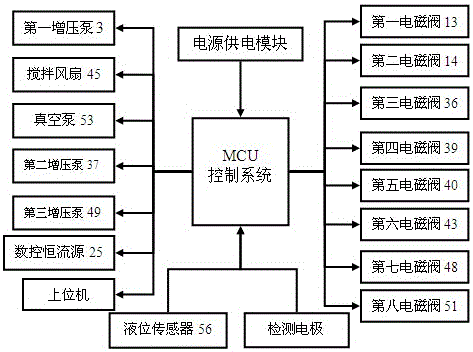

[0028] The membrane damage detection device of the flat membrane module of the present invention includes a raw liquid tank 1, a first booster pump 3, an MCU control box 4, a liquid storage tank 16, a bacteria concentration detection device 18, and a solenoid valve. The MCU control box 4 is placed on the upper surface of the upper splint 7. The MCU contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com